Finding the Perfect Cardamom Sorter for Your Needs

Selecting the right sorter is a critical investment. It directly impacts product market value and operational efficiency. The global cardamom market shows strong growth projections, underscoring the need for superior processing. A high-quality cardamom sorting machine helps businesses capitalize on this expanding market opportunity.

| Year | Market Value (USD Billion) |

|---|---|

| 2024 | 1.51 |

| 2032 | 2.38 |

Understanding Core Sorting Technologies

The first step in choosing a sorter is understanding the technology that powers it. Different machines use distinct methods to identify and separate cardamom based on specific quality attributes. Processors can achieve comprehensive quality control by selecting a machine with the right technology, or a combination of technologies, to meet their specific sorting goals.

Color Sorters (CCD) for Visual Defects

Color sorters equipped with Charged-Couple Device (CCD) cameras are the industry standard for identifying visual imperfections. These machines use high-resolution cameras to scan each cardamom pod as it passes through the inspection zone. Advanced software then analyzes these images in real-time, comparing them against pre-defined quality parameters set by the operator.

This technology excels at detecting:

- Discoloration: Yellow, brown, or black pods.

- Blemishes: Spots, insect damage, or physical marks.

- Maturity: Immature or shriveled green pods.

- Foreign Material: Sticks, stones, or other contaminants with a contrasting color.

When the system identifies a defective pod, it signals a high-speed pneumatic ejector to release a precise puff of compressed air, removing the unwanted item from the main product stream. The accuracy and efficiency of these machines are critical performance indicators. Modern sorters achieve exceptional accuracy rates, ensuring a high-purity final product while minimizing the loss of good pods.

Key Performance Metrics 📈 When evaluating a CCD sorter, focus on its sorting accuracy, throughput (capacity), and carryover ratio. The carryover ratio (e.g., 12:1) indicates how many bad items are rejected for every one good item that is accidentally rejected, measuring the machine's precision.

Below are typical specifications for a single-chute cardamom sorting machine and a multi-chute model series, illustrating how capacity scales with machine size.

| Parameter | Value |

|---|---|

| Sorting Accuracy (%) | ≥99.9 |

| Capacity (kg/hour) | 400kg–500kg |

| Carryover Rate (bad:good) | ≥12:1 |

| Voltage | 220V/50Hz |

| Weight (kg) | 350 |

| Dimension (L*W*H) mm | 910*1620*1550 |

Note: These parameters are based on sticky rice with impurity within 2% and may vary for different materials and impurity levels.

| Model | Channels | Throughput (t/h) | Accuracy (%) | Optimized Carryover |

|---|---|---|---|---|

| ZM3 | 192 | 2–5 | 99.99 | ≥12:1 |

| ZM4 | 256 | 2.5–6 | 99.99 | ≥12:1 |

| ZM5 | 320 | 3.5–8 | 99.99 | ≥12:1 |

Note: These parameters are for reference only and may vary based on raw material types and contamination rates.

Size and Shape Sorters for Grading

Cardamom's market value is heavily influenced by pod size. Larger, more uniform pods command higher prices. Size and shape sorters are essential for grading cardamom into consistent lots that meet specific market demands.

Common industry grades are determined by the diameter of the pod.

| Grade | Size |

|---|---|

| Small | 6mm to 8mm |

| Medium | 8mm to 10mm |

| Large | >10mm |

| Bold | >8mm |

| Super Bold | >10mm |

The most common technology for this task is the mechanical vibratory screen, or sifter. These machines use a multi-deck system with screens of varying mesh sizes. The process is straightforward yet effective:

- Feeding: Cardamom is fed into an inlet hopper at the top of the machine.

- Vibration: A powerful motor generates an adjustable tumbling motion, causing the pods to move in a spiral pattern across the screen surfaces.

- Separation: As the pods travel, smaller ones fall through the mesh openings to a lower deck, while larger pods remain on top.

- Discharge: Each deck funnels its separated size grade to a distinct outlet, resulting in precisely sorted batches.

This mechanical method is highly efficient for classifying large volumes of cardamom and removing unwanted particles like fine dust or broken pieces.

X-Ray and Infrared (IR) for Purity

For the highest level of product safety, processors turn to X-ray and Infrared (IR) technologies. These systems inspect for contaminants that are invisible to the naked eye and may not be caught by color or size sorters.

X-ray inspection systems are masters at detecting foreign bodies based on density. The system passes low-energy X-rays through the cardamom. Denser materials absorb more X-rays than the less-dense organic pods. This differential absorption creates a contrast on a grayscale image, allowing the system to identify and reject contaminants like:

- Metal fragments (wires, shavings)

- Glass shards

- Stones and rubble

- High-density plastics and bone

Essentially, if a contaminant is denser than water, an X-ray system can likely detect it, even if it is hidden inside the cardamom pod itself.

Infrared (IR) sorters, particularly those using Short-Wave Infrared (SWIR), analyze the chemical and molecular structure of materials. This technology is excellent for distinguishing cardamom pods from foreign organic matter like shells, hulls, or other plant materials that may have a similar color and size. It can also detect variations in moisture content, helping to identify improperly dried pods.

Matching Machine Capacity to Your Production Volume

Selecting a machine with the right capacity is essential for maintaining a smooth and efficient workflow. A sorter that is too small creates bottlenecks during peak seasons. A sorter that is too large results in unnecessary capital expenditure and higher operational costs. The goal is to match the machine's throughput directly to your production volume.

How to Calculate Your Throughput Needs

Processors should base their throughput calculations on peak production, not daily averages. Cardamom harvests are highly concentrated. Several factors create significant spikes in volume that a sorting system must handle.

Key production variables include:

- Harvest Concentration: Approximately 66% of the annual yield can occur within a concentrated four-month period.

- Plantation Age: Peak agronomic yield often occurs in mature, 20-year-old stands.

- Climatic Conditions: Rainfall and humidity levels directly influence harvest size and timing.

- Agricultural Practices: Techniques like shade lopping can alter yield patterns.

To calculate your required throughput, determine your maximum daily processing volume during these peak times. Divide this total weight (in kilograms) by your daily operational hours. The result is your required throughput in kilograms per hour (kg/h). This figure provides a reliable benchmark for choosing a machine.

Balancing Sorting Speed and Accuracy

Machine capacity is often presented as a range (e.g., 2–5 tons per hour). This reflects the inherent trade-off between sorting speed and sorting accuracy. Running a cardamom sorting machine at its absolute maximum speed can sometimes compromise its precision. Ejectors may struggle to keep up, potentially leading to a higher carryover ratio.

The optimal operational point is where the machine processes the maximum volume possible while still meeting the required quality standards. Sacrificing accuracy for speed can devalue the final product and negate the benefits of sorting.

Processors should test a machine at various speeds during a demonstration. This helps them identify the "sweet spot" that balances throughput with the high accuracy needed to maximize profitability and product quality.

Key Features of a High-Performance Cardamom Sorting Machine

Beyond core technology, specific features determine a machine's daily performance and long-term value. Processors should examine the ejector system, software interface, and physical design. These elements directly influence operational efficiency, product quality, and overall profitability.

Ejection System Precision and Efficiency

The ejection system is where sorting decisions become reality. High-performance machines use high-speed ejectors that react instantly to signals from the control system. These systems typically employ precise jets of compressed air to remove defective pods or foreign materials from the product stream. An efficient system ensures maximum removal of unwanted items. It also minimizes the accidental rejection of good cardamom, protecting profits. Some systems also use air jets for automatic cleaning of the sorting channels.

Intuitive Software and Control Interface

Modern software simplifies the operation of a complex cardamom sorting machine. An intuitive, user-friendly interface allows operators to adjust sorting parameters with ease. Key features include:

- Pre-set Profiles: Operators can save hundreds of sorting profiles for different grades or contamination levels, enabling a 'one-button' start for various batches.

- Multiple Sorting Modes: The software offers different modes, such as single-color or multi-color sorting, for maximum flexibility.

Remote Capabilities 🌐 Advanced systems offer remote access through cloud connectivity. Technicians can perform remote diagnostics and maintenance, while managers can monitor performance from a mobile device or tablet. This functionality significantly reduces downtime.

Design for Easy Cleaning and Maintenance

Proper sanitation is non-negotiable in food processing. A well-designed machine facilitates quick and thorough cleaning. Manufacturers use food-grade materials like Stainless Steel 304, which is non-porous and corrosion-resistant, to comply with food safety standards like FDA and EU 1935/2004. Top-tier machines also feature tool-less removal of food-contact components. This allows operators to quickly disassemble chutes, belts, and dividers for deep cleaning, ensuring hygiene and maximizing operational uptime.

Budgeting and Calculating Return on Investment (ROI)

An effective budget requires a comprehensive view of all expenses associated with a cardamom sorting machine. Processors must look beyond the initial purchase price to understand the Total Cost of Ownership (TCO). This approach provides a more accurate financial picture and prevents unexpected costs down the line. A thorough TCO analysis is the foundation for calculating a realistic Return on Investment (ROI).

Evaluating the Total Cost of Ownership

The initial sticker price is only one part of the total investment. A complete financial assessment includes all direct and indirect costs over the machine's lifespan. Processors should account for several key factors.

- Initial Purchase Price: This varies significantly based on technology, capacity, and features.

- Installation and Training: Costs for installation, testing, and commissioning are crucial. Expenses for training operators and maintenance staff are also significant and depend on the equipment's complexity.

- Operational Costs: These include electricity consumption, compressed air usage, and routine spare parts.

- Maintenance and Support: Consider the cost of service contracts, warranty coverage, and the availability of technical support.

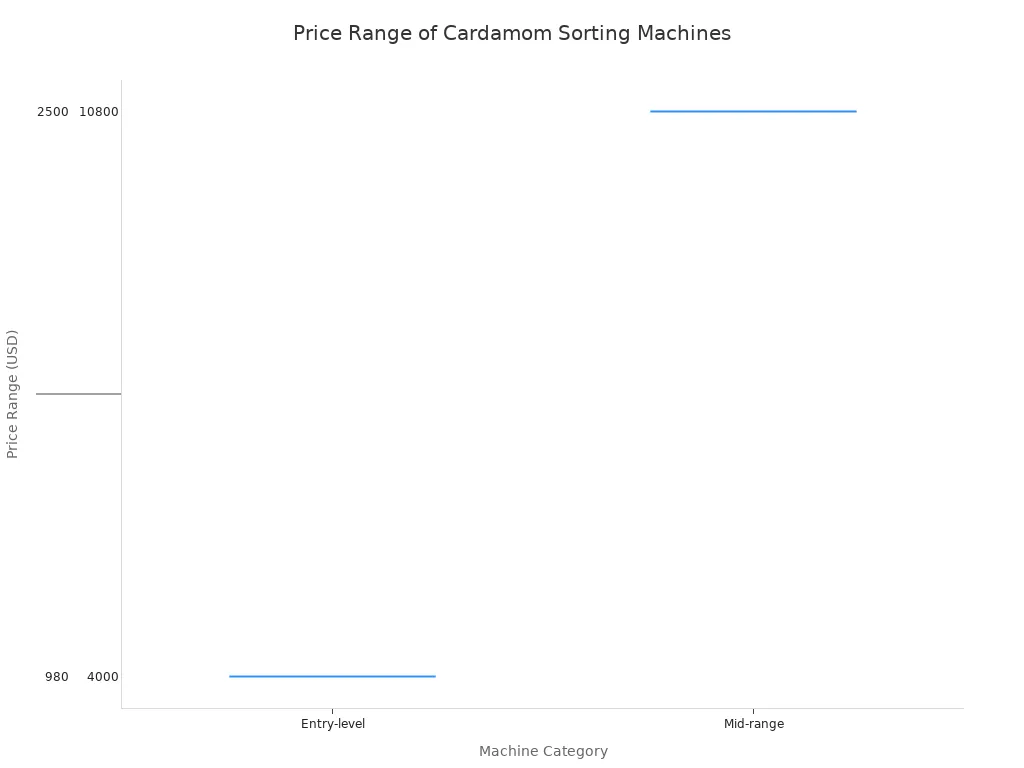

The price of a sorter can range widely, reflecting its capabilities.

| Category | Price Range | Example Machine Type |

|---|---|---|

| Entry-level | $980 - $2,500 | Automatic Grain Cardamom Beans Color Sorter, Double Layer Cardamom Vibration Sorting Machine |

| Mid-range | $4,000 - $10,800 | Single Chute Multi-function CCD Color Sorter, Cardamom Sorter, Wenyao 64 Channel, New Food Grade Sorting Machine |

| High-end | $28,000 - $36,666 | Professional Chute Style Fennel Pepper Cardamom Condiment Color Sorting Machine, Cashew Cardamom Colour Sorter Machine |

Calculating Your Potential ROI

Calculating the potential ROI helps justify the investment. It measures the profitability of the machine by comparing the financial gains against the total cost.

ROI Formula 💡

ROI (%) = [(Financial Gain - Total Cost of Investment) / Total Cost of Investment] x 100

Key financial gains include:

- Increased Revenue: Higher prices for consistently graded, high-purity cardamom.

- Reduced Labor Costs: Automation significantly decreases the need for manual sorting.

- Minimized Product Loss: Efficient ejection systems reduce the amount of good product that is wasted.

By quantifying these benefits and subtracting the TCO, a processor can determine how quickly the machine will pay for itself and begin generating profit.

Processors choose correctly by aligning machine technology with business goals.

Final Checklist ✅ A final check includes requesting demos, seeking references, and reviewing warranty agreements, which typically offer 12–24 months of coverage.

A well-chosen sorter elevates product quality through uniform grading, reduces labor costs, and maximizes profitability.

FAQ

What is the most important factor when choosing a sorter?

Processors should align the machine's technology with their specific sorting needs. This ensures the sorter meets business goals for color, size, or purity.

How much maintenance do these machines require?

Maintenance needs vary by model. Daily cleaning is essential for hygiene. Operators perform regular checks on ejectors and cameras to prevent downtime and ensure consistent performance.

Can one machine sort for both color and size?

Some advanced sorters combine technologies. Processors often use separate machines for color and size. This approach provides more specialized and efficient results for each task.

See Also

Capsule Sorters: Essential Technology for Flawless Product Quality Assurance

Selecting the Ideal Tablet Sampling Machine for Your Laboratory Needs

Top Capsule Checkweighers: A Buyer's Guide for the Year 2025

Selecting the Optimal A1 A2 Milk Test Kit for Dairy Operations

Three Essential Industrial Checkweighers for Every Modern Food Processing Plant