Everything You Need to Know About Black Bean Sorters

An excellent choice for a black bean sorter requires a careful evaluation of four key factors. Processors must analyze sorting technology, performance metrics, operational costs, and overall usability. This guide examines these criteria. It helps select the best black beans sorting machine for specific operational needs.

What Are the Core Sorting Technologies?

Processors primarily use three types of sorting technology to ensure black bean quality. Each technology offers distinct methods for identifying and removing defects. The choice depends on the product's fragility and the specific contaminants targeted for removal.

Chute-Type Color Sorters

Chute-type sorters use gravity to move black beans down channels at high speed. As beans pass through a detection zone, high-resolution cameras scan them. An image processing system identifies impurities based on color, size, and shape. High-pressure air jets then precisely eject defective beans from the main stream. This type of black beans sorting machine offers significant processing power, with throughput varying by model.

| Model | Throughput (t/h) |

|---|---|

| TD-1 | 1-3 |

| TD-4 | 2.5-6.5 |

| TD-8 | 6-14 |

| TD-10 | 8-16 |

Belt-Type Color Sorters

Belt-type sorters provide a gentler alternative for more fragile products. The beans travel on a stable, horizontal belt, which minimizes impact and reduces breakage.

💡 Pro Tip: The stable transmission of a belt sorter is ideal for preserving the integrity of delicate products. It significantly reduces the risk of collision and damage during the sorting process.

This method ensures that the final product remains intact, which is crucial for maintaining high market value.

Advanced Sorting Technologies (IR, X-ray)

Advanced technologies like Infrared (IR) and X-ray go beyond visual inspection. X-ray inspection machines identify foreign materials based on density differences. This allows them to detect contaminants that cameras cannot see, such as:

- Glass fragments

- Stones

- High-density plastics

- Metal pieces

This capability is critical for food safety, as agricultural products can contain potentially toxic elements like Chromium (Cr) and Arsenic (As). An advanced black beans sorting machine enhances product quality and helps producers meet stringent safety demands for premium food.

How to Evaluate a Black Beans Sorting Machine

Operators must assess several key performance indicators to select the right equipment. A thorough evaluation of accuracy, capacity, and sensor technology ensures the chosen machine aligns with production goals and quality standards. This analysis forms the foundation for a successful investment.

Sorting Accuracy and Rejection Ratio

Sorting accuracy measures a machine's ability to correctly identify and remove defects. The industry benchmark for high-quality sorters is exceptionally high. Modern machines, especially those with deep learning capabilities, can achieve an accuracy of 99.99% when sorting for issues like wormholes or discoloration. This level of precision is critical for delivering a premium final product.

A closely related metric is the rejection ratio, sometimes called the carry-over rate. It quantifies the amount of good product mistakenly ejected along with the defects. An ideal black beans sorting machine minimizes this ratio.

Note: A low rejection ratio is crucial for profitability. Ejecting too many good beans directly impacts yield and revenue. Operators should test machines with their own product to verify both accuracy and the rejection ratio before purchasing.

Capacity and Throughput

Capacity, or throughput, refers to the volume of black beans a machine can process in a given time, usually measured in kilograms or tons per hour. This metric is fundamental. It must match or exceed the facility's production requirements. A mismatch can create bottlenecks or leave expensive machinery underutilized.

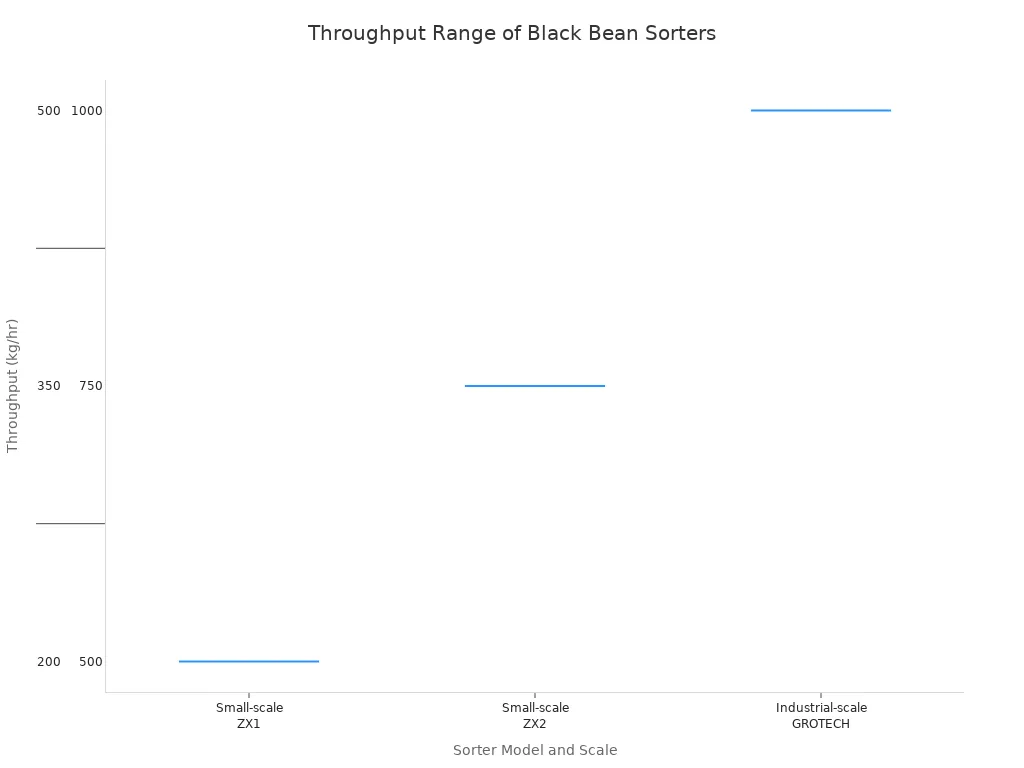

Throughput varies significantly based on the machine's scale. Small-scale operations may only need a sorter that handles a few hundred kilograms per hour. Industrial-scale facilities require robust systems capable of processing many tons per hour.

| Scale of Operation | Typical Throughput Range (kg/hr) |

|---|---|

| Mini Sorters | 10–200 |

| Small to Medium Operations | 200–1,000 |

| Industrial-Scale | 5,000–30,000+ |

The following chart illustrates how throughput capabilities expand from smaller models to large industrial machines.

Choosing the right capacity involves planning for future growth. A black beans sorting machine should not only meet current needs but also accommodate anticipated increases in production volume.

Camera and Sensor Resolution

The effectiveness of a black beans sorting machine depends heavily on its "eyes"—the cameras and sensors. Resolution determines the smallest defect size the machine can detect. Higher resolution allows the system to identify minuscule imperfections that would otherwise be missed.

Modern sorters feature impressive capabilities:

- Ultra-fine detection: Some systems can spot stains and imperfections as small as

0.04 mm. - High-resolution optics: Other advanced sorters have an optical resolution capable of discerning features at

0.5x0.5 mm. - Standard precision: Even standard ultra-high resolution systems reliably detect defects and foreign objects down to

1 mm.

This level of detail is essential for removing subtle defects like small spots, cracks, or embedded foreign material. High-resolution sensors empower processors to meet the strictest quality standards demanded by premium markets. They ensure the final product is uniform, clean, and free of blemishes.

What Are the Financial Considerations?

A smart investment in a black beans sorting machine extends beyond the initial price tag. Processors must conduct a thorough financial analysis. This involves calculating the complete cost over the machine's lifespan and projecting the financial returns it will generate. A clear financial picture justifies the purchase and ensures long-term profitability.

Calculating Total Cost of Ownership (TCO)

The purchase price is only the beginning. The Total Cost of Ownership (TCO) provides a comprehensive view of all expenses associated with the sorter. A careful TCO calculation prevents unexpected costs and allows for accurate budgeting. Key components include:

- Acquisition Costs: The initial purchase price of the machine.

- Operating Costs: Expenses from energy consumption and routine maintenance.

- Personnel Costs: The investment in staff training and operation.

- Downtime: Lost revenue from periods when the machine is not operational.

- Disposal Costs: Expenses to remove the asset at the end of its life.

Evaluating these factors gives a true financial measure of the equipment.

Estimating Your Return on Investment (ROI)

Return on Investment (ROI) measures the profitability of the black beans sorting machine. It compares the net profit generated by the sorter to its total cost. A positive ROI confirms the equipment is a valuable asset. Operators can calculate ROI with a simple formula.

(Net Profit / Total Investment) x 100 = ROI (%)

For example, a sorter costs $200,000 and generates an annual net profit of $50,000 from increased yield and quality. The ROI would be 25% ($50,000 ÷ $200,000 x 100). This powerful metric demonstrates the sorter's financial benefit, making it a crucial part of the decision-making process.

What Practical Factors Should You Consider?

Beyond performance metrics, practical considerations heavily influence a sorter's long-term value. Processors should evaluate the machine's daily usability, maintenance demands, and the quality of manufacturer support. These factors ensure smooth integration into existing workflows and maximize operational uptime.

Ease of Use and Programming

A modern black beans sorting machine should simplify operations, not complicate them. User-friendly interfaces are essential for efficient production. Many systems feature intelligent software with intuitive controls. Key features include:

- A smart touchscreen interface for easy navigation.

- Real-time monitoring of the sorting process.

- Simple adjustment capabilities to optimize sorting parameters.

This design allows operators to track performance and make necessary changes with minimal effort. An intuitive graphical user interface reduces the learning curve and helps minimize operational errors.

Maintenance and Cleaning

Consistent maintenance is critical for keeping sorting equipment in peak condition. Regular cleaning prevents dust and debris from interfering with sensors and ejectors. Operators should follow a structured maintenance schedule. Daily tasks often involve using an air gun to clean dust from chutes and nozzles and wiping the sorting box glass. Monthly procedures may include deeper cleaning of circuit boards and verifying the function of each ejector valve. A well-maintained machine delivers reliable accuracy day after day.

Manufacturer Support and Training

Reliable manufacturer support is a crucial safety net. Leading suppliers offer comprehensive assistance, including technical support, software updates, and spare parts replacement. This continuous support maximizes uptime throughout the product's life. Training is another vital component. Some manufacturers provide highly efficient training programs.

“We can install, train, and start sorting in the same day. With only two hours of training, a new operator will be 100 percent proficient.”

Processors should also verify the warranty. Standard warranties typically cover one to two years, with some offering extended coverage for critical components.

Processors make the right choice by balancing technology, performance, cost, and usability. A final checklist helps guide this decision:

- Define your quality standards.

- Calculate your capacity needs.

- Test machines with your own beans.

- Compare the total cost of ownership.

A well-chosen sorter is a powerful investment, positioning operations for future efficiency gains from AI and Industry 4.0 integration.

FAQ

Can one sorter handle different types of beans?

Yes. Modern sorters have programmable settings. Operators create and save sorting profiles for various beans. This feature allows one machine to handle black beans, soybeans, and more.

How does lighting affect sorting accuracy?

Consistent lighting is crucial for accurate sorting. LED lighting provides stable, long-lasting illumination. This ensures cameras capture clear images, which improves the machine's defect detection capabilities.

What is the typical lifespan of a black bean sorter?

A well-maintained black bean sorter can operate for over a decade. Its lifespan depends on build quality, operating hours, and consistent adherence to the manufacturer's maintenance schedule.

See Also

Capsule Sorters: Essential Technology for Flawless Product Quality and Defect Elimination

Key Capsule Checkweighers for Smart Buyers to Evaluate in the Year 2025

Three Indispensable Industrial Checkweighers for Optimal Food Plant Operations

Defining Pharmaceutical Checkweighers: Understanding Their Crucial Features and Functions

Tablet Sampling Machines Unveiled: A Comprehensive Guide for Laboratory Selection