The Smart Farmer's Choice an Asparagus Optical Sorter Guide

Farmers find the "best" asparagus optical sorter matches their farm's unique needs. The agricultural sorting machinery market projects approximately 7% CAGR, showing a trend toward automation. Choosing the right machine hinges on a clear understanding of sorting criteria, technology, and potential return on investment for the operation.

Note: A smart selection process directly boosts farm efficiency and profitability. 📈

The Business Case for an Asparagus Optical Sorter

Investing in sorting technology is a strategic business decision. It moves a farm's operations from a labor-intensive model to a technology-driven one. This shift provides a clear competitive advantage by improving efficiency, quality, and market access. The right machine delivers a strong return by addressing key operational challenges.

Reduce Labor Costs and Increase Throughput

Manual sorting requires a large team and limits processing speed. An asparagus optical sorter automates this critical step, allowing growers to reallocate labor to other essential tasks. This automation drastically improves operational efficiency and boosts the volume of asparagus processed per hour. The difference in productivity is substantial.

| Sorting Method | People Required | Throughput (tons per hour) |

|---|---|---|

| Optical Sorting | 3 | 4 - 6 |

| Traditional Hand Sorting | 12 | 1 - 1.5 |

Maximize Marketable Yield with Precision

Human sorters can miss minor defects during long shifts. Optical sorters use advanced cameras and sensors to analyze each spear. They detect subtle color variations, blemishes, and shape irregularities with exceptional accuracy. This precision recovers spears that might otherwise be discarded, increasing the total marketable volume from every harvest.

Command Higher Prices with Consistent Quality

Buyers and retailers value product uniformity. Consistent batches of asparagus that meet specific size and grade requirements are more attractive in the marketplace. This reliability allows growers to build a reputation for excellence and command higher prices for their premium product.

A reputation for consistent, high-grade asparagus directly translates to better market positioning and increased revenue. 💰

Meet Strict Retail and Export Standards

Export markets offer significant opportunities but come with strict import regulations. Key markets like Japan and the European Union enforce specific rules that growers must follow.

- Japan:

- Requires a phytosanitary certificate for all consignments.

- Conducts import inspections upon arrival.

- European Union (EU):

- Requires phytosanitary certificates for fresh produce.

- Enforces strict Maximum Residue Limits (MRLs) for agrochemicals.

Growers must also account for tariffs on their products.

| Market | Asparagus Type | Tariff Rate |

|---|---|---|

| Japan | Fresh or chilled | 3.0% |

| European Union | Fresh or chilled | 10.2% |

An asparagus optical sorter ensures every spear meets these complex standards, securing access to lucrative international markets.

Essential Features of a Modern Asparagus Sorter

Modern sorters offer sophisticated analysis of each spear. They go far beyond simple manual inspection. An asparagus optical sorter evaluates multiple attributes simultaneously to ensure every spear is categorized correctly. Understanding these core features helps growers select a machine that meets their specific quality and market demands.

Sorting by Diameter and Length

Diameter and length are the most fundamental sorting criteria. They directly determine the product's grade and market value. Sorters use high-resolution cameras and laser scanners to measure each spear with sub-millimeter precision. This automated process guarantees uniformity within each box, a key requirement for retail and food service buyers.

Pro Tip: Precise size grading allows growers to create multiple product tiers from a single harvest, maximizing revenue from different market segments. 🎯

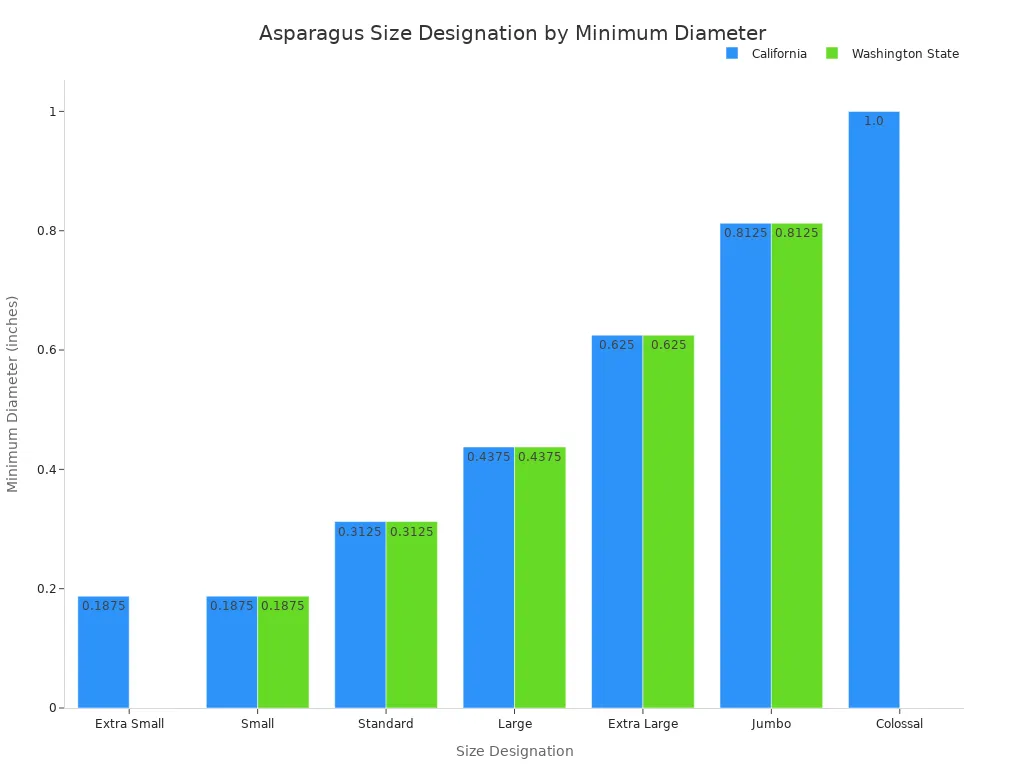

Market standards for diameter can vary by region. Growers must configure their sorters to match the specific requirements of their target buyers. For example, size designations in California differ from those in Washington State.

Comparison of California & Washington State Size Designations

A sorter can be programmed to classify spears into common industry grades, ensuring compliance and market acceptance.

| Size Designation | Minimum Diameter (inches) |

|---|---|

| Small | 3/16 |

| Standard | 5/16 |

| Large | 7/16 |

| Extra Large | 10/16 |

| Jumbo | 13/16 |

| Colossal | 1 |

Detecting Color and Blemishes

Quality is more than just size. Sorters use advanced RGB (Red, Green, Blue) and infrared (IR) cameras to assess the color and surface integrity of each spear. This technology identifies a wide range of imperfections that impact grade and shelf life.

- Color Grading: Machines can distinguish between green, white, and purple asparagus. They also detect yellowing or fading, which can indicate age or stress.

- Blemish Detection: The system identifies and flags spears with insect damage, rust spots, scarring, or mechanical bruising.

- Tip Quality: Sorters analyze the spear tip for signs of opening or decay, which are critical quality indicators.

Advanced systems utilize hyperspectral imaging (HSI) to see beyond what the human eye can. HSI technology detects minute chemical changes in a spear. This allows the machine to identify the early stages of rot or physiological stress by observing spectral changes influenced by moisture levels and photosynthetic activity. This early detection prevents compromised spears from entering the premium supply chain.

Analyzing Spear Shape and Curvature

Spear straightness is crucial for efficient packing and consumer appeal. Bent or misshapen spears are difficult to bunch and can lead to package damage. Modern sorters use multiple cameras or 3D imaging to create a complete topographical map of each spear.

This 360-degree analysis allows the system to measure curvature along the entire length of the spear. The machine then sorts the spears based on pre-defined straightness parameters. This ensures that only straight, uniform spears are packed for premium markets, while curved spears can be diverted for processing or value-added products.

| Spear Characteristic | Sorting Action |

|---|---|

| Straight or Slight Curve | Accepted for premium bunching |

| Significant Bend or "J" Shape | Diverted to processing grade |

| Twisted or Deformed | Culled or sent to lower grade |

Evaluating Sorter Technology and Performance

Choosing the right machine requires a deep dive into its technical specifications. Growers should assess a sorter's performance based on its processing speed, precision, and underlying technology. These factors directly influence operational efficiency and the return on investment.

Throughput Capacity (Tons/Hour)

Throughput capacity measures how many tons of asparagus the machine can process per hour. This metric is critical for matching the sorter to a farm's scale. A small farm may not need the highest capacity, while a large commercial operation requires a machine that can keep pace with peak harvest volumes without creating bottlenecks. Evaluating a sorter’s throughput ensures it aligns with current and future production goals.

Sorting Accuracy and Error Rate

Accuracy determines how well the machine classifies spears based on set criteria. Research shows computer vision techniques can achieve an overall accuracy of 90.2%. A key related metric is the 'false reject rate'—the percentage of good products incorrectly discarded. Leading manufacturers minimize this with advanced techniques.

- Innovative ejection algorithms reduce mistaken rejections.

- New calibration and tracking algorithms improve machine consistency.

Some advanced sorters are designed to achieve a false reject rate of less than 1%, maximizing the marketable yield from every harvest.

Camera, Sensor, and Software Capabilities

The sorter's "eyes" and "brain" are its camera, sensors, and software. Modern systems use machine learning approaches, like Support Vector Machines (SVM), to improve accuracy over time. The software analyzes huge datasets of spear images, allowing the asparagus optical sorter to learn from sample variations and reduce errors. This continuous learning ensures the machine adapts and maintains high performance season after season.

Ease of Use and System Integration

Advanced technology must be accessible to the farm team. Sorters with intuitive, user-friendly interfaces, sometimes mimicking smart device apps, allow operators to create and manage sorting programs easily. A sorter is also part of a larger system. It must integrate seamlessly with existing equipment like conveyors and packing lines to create an efficient, automated workflow from field to box.

Your Step-by-Step Selection Checklist

Selecting an optical sorter is a significant capital investment. A structured evaluation process ensures the chosen machine aligns perfectly with a farm's operational realities and financial goals. This checklist guides growers through a methodical approach, from internal assessment to final vendor selection.

Step 1: Define Your Operational Needs

A successful selection process begins with a thorough internal audit. Growers must first quantify their specific requirements to create a clear benchmark for evaluating different sorters. This foundational step prevents overspending on unnecessary capacity or underspending on a machine that fails to meet production demands.

Key questions help define these needs:

- Harvest Volume: What is the peak daily and hourly volume of asparagus that requires processing? The sorter must handle this peak without creating a bottleneck.

- Product Mix: Does the farm produce green, white, or purple asparagus? The sorter's cameras and software must be capable of handling the specific varieties grown.

- Quality Grades: How many different grades (based on diameter, length, color, and straightness) does the operation need to sort for?

- Market Requirements: What are the specific quality standards for the farm's primary buyers, including retail, food service, and export markets?

Meeting market requirements often involves adhering to voluntary but critical certification programs. These programs establish clear standards for food safety and handling that a sorter can help enforce.

Good Agricultural Practices (GAP) and Good Handling Practices (GHP) are programs that help ensure a safer food system. Many major food distributors now require GAP and GHP certification from their producers. These programs set standards for worker hygiene, water quality, and other operational factors. Farms must develop a food safety plan and pass a third-party inspection. An optical sorter is a key tool for consistently meeting the quality benchmarks these programs demand.

Step 2: Calculate Your Potential ROI

An optical sorter is a tool for profitability. A return on investment (ROI) calculation provides the financial justification for the purchase. It compares the total cost of ownership against the projected financial gains. A positive ROI demonstrates the investment's value as a strategic asset.

The calculation involves two main components: total investment and financial returns.

| ROI Component | Description |

|---|---|

| Investment Costs | Includes the machine's purchase price, shipping, installation fees, operator training, and projected annual maintenance costs. |

| Financial Returns | Includes direct labor cost savings, revenue from increased marketable yield, price premiums for consistent quality, and access to new, higher-paying markets. |

A simple way to conceptualize the ROI is with the formula:

ROI (%) = (Net Financial Gain - Total Investment Cost) / Total Investment Cost * 100

A detailed analysis provides a clear timeline for when the sorter will pay for itself and begin generating net profit for the operation. 📈

Step 3: Vet Vendors and Request Demos

The long-term success of an optical sorter depends heavily on the manufacturer. A reliable vendor provides not just a machine, but also robust support, training, and service. Growers should thoroughly investigate potential suppliers before making a commitment.

The vetting process should follow a clear sequence:

- Research the Market: Identify leading global manufacturers. Some companies, like Maf-Roda, provide a comprehensive range of solutions for asparagus grading and weighing, expanding their offerings through strategic acquisitions of specialized firms like Strauss. Researching these vendors reveals their expertise and the breadth of their technology.

- Create a Shortlist: Based on initial research, create a shortlist of 2-3 vendors whose machines appear to meet the operational needs defined in Step 1.

- Ask Detailed Questions: Engage with sales representatives. Inquire about throughput, sorting accuracy, software capabilities, warranty, service response times, and the availability of spare parts.

- Request a Demonstration: This is the most critical part of the vetting process. A demo validates a manufacturer's claims.

Actionable Insight: Always request a product demonstration using your own asparagus. Shipping a representative sample to the vendor allows you to see exactly how the machine will perform with your crop's specific characteristics. This real-world test is the best way to confirm sorting accuracy and efficiency.

A thorough evaluation of the technology and the vendor behind it empowers growers to make a confident, informed decision that will benefit their operation for years to come.

A grower's final decision hinges on three factors: sorting accuracy, throughput capacity, and reliable vendor support. Investing in the right asparagus optical sorter is a strategic move enhancing efficiency and profitability. This guide empowers growers to confidently select a machine, securing their competitive advantage in the market.

FAQ

Can one sorter handle green, white, and purple asparagus?

Yes. Advanced sorters use RGB cameras and specific software programs. Growers easily configure the machine to accurately grade green, white, and purple varieties based on unique parameters.

How much maintenance does an optical sorter require?

Sorters require daily cleaning of cameras and belts. Vendors provide preventive maintenance schedules. Following these guidelines ensures consistent performance and protects the grower's investment. 🛠️

How difficult is it to operate an asparagus sorter?

Modern sorters have user-friendly interfaces similar to smart devices. Vendors offer complete operator training. Farm teams can quickly learn to manage sorting programs and daily functions.

See Also

Essential Industrial Checkweighing Machines for Optimal Food Production Facilities

Capsule Sorters: Key Equipment for Effective Pharmaceutical Defect Elimination

Leading Capsule Checkweighers for Informed Purchasing Decisions in 2025

Tablet Sampling Machines: A Comprehensive Guide for Laboratory Equipment Selection

Comparing Top Ampoule Filling Production Line Manufacturers for Your Needs