Find the Perfect Asparagus Optical Sorter for You

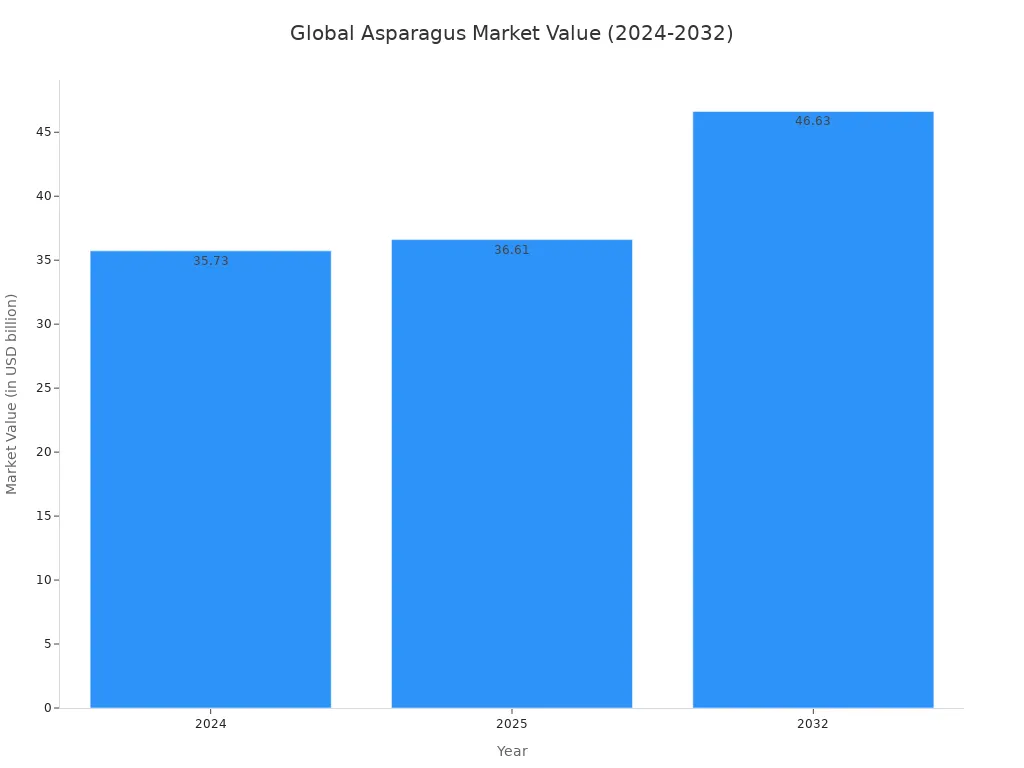

Selecting the right asparagus optical sorter is a critical decision for modern producers. The global asparagus market is projected to reach USD 46.63 billion by 2032, driven by strong consumer demand for fresh, high-quality produce. Growers must evaluate three core factors to make an informed choice. These include specific sorting criteria like quality and size, required processing capacity, and the machine's integration with existing production lines.

Define Your Core Sorting Needs

The first step in selecting an asparagus optical sorter is to define your operation's specific requirements. A clear understanding of your sorting goals ensures the chosen machine delivers maximum value. Producers must evaluate their needs across quality, size, and color to establish a baseline for equipment performance.

Quality and Defect Detection

Maintaining high product quality is essential for market competitiveness. Modern sorters use advanced machine vision and artificial intelligence to identify imperfections in real-time. This technology allows the machine to detect a wide range of common asparagus defects.

Key Defects to Target: An effective sorter should accurately identify and remove spears with issues like:

- Freeze injury: Bent spears that break down and show internal discoloration.

- Wind damage: Spears that bend due to uneven drying from heavy winds.

- Mechanical injury: Abrasions from rocky soils that cause spears to become contorted.

- Insect damage: Curvature caused by pests like cutworms feeding on one side.

- Cutting knife damage: Nicks from harvesting that lead to poor development.

Diameter and Length Grading

Consistent sizing is a critical parameter for packaging, pricing, and meeting buyer specifications. An optical sorter automates this labor-intensive task with exceptional precision. It measures the diameter and length of each spear, sorting them into predefined categories. These classifications often follow established industry standards.

| Classification | USDA Diameter (inches) | California Minimum Diameter (inches) |

|---|---|---|

| Small | 5/16 to < 8/16 | 3/16 |

| Medium | 8/16 to < 11/16 | N/A |

| Large | 11/16 to < 14/16 | 7/16 |

| Jumbo | N/A | 13/16 |

| Colossal | N/A | 1 |

Color and Freshness Sorting

Color is a primary indicator of freshness for consumers. Sorters analyze the spectral data of each spear to grade it based on color. This process ensures that only spears with a vibrant, uniform green color proceed to packaging. The machine effectively rejects spears that are yellowing, browning, or show signs of wilting, protecting brand reputation and reducing waste.

Key Features of an Asparagus Optical Sorter

After defining your sorting needs, the next step involves examining the machine's technical components. The hardware and software features determine the sorter's efficiency, accuracy, and ease of use. Understanding these key features helps producers compare different models effectively.

Sensor and Camera Technology

The "eyes" of an asparagus optical sorter are its sensors and cameras. This technology is the foundation of its sorting capability. High-resolution cameras capture detailed images of each spear from multiple angles as it passes through the machine. These cameras work alongside specialized sensors, such as:

- RGB (Red, Green, Blue) Cameras: These full-color cameras are excellent for identifying variations in color, which helps grade freshness and detect yellowing or browning.

- Infrared (IR) and Near-Infrared (NIR) Sensors: These sensors detect properties invisible to the naked eye. They can identify subsurface defects, moisture content, and subtle differences in texture that indicate quality issues.

- 3D Laser Scanners: These systems create a three-dimensional model of each spear. This allows for precise measurement of diameter, length, and curvature, ensuring accurate size grading.

The combination of these technologies provides a comprehensive view of each spear, enabling the machine to make sorting decisions based on a complete quality profile.

Ejection System Precision

Once the sorter identifies a spear for removal, the ejection system physically separates it from the main product flow. The precision of this system is critical. A high-precision system uses targeted air jets to remove only the defective spear without disturbing adjacent good spears.

Minimizing Good Product Loss The precision of an ejection system directly impacts the rate of good product being accidentally rejected. Advanced systems enhance quality assurance and are designed to minimize these false reject rates. Precise data analysis allows for real-time analytics and comparison with historical data, which improves quality control and prevents false rejections. This data collection also contributes to overall process improvements, leading to fewer errors over time.

Operators must balance detection sensitivity with productivity. This balance is often achieved through careful tuning during installation, which ultimately reduces the accidental rejection of valuable products and maximizes yield.

Software and User Interface

The software is the brain of the operation, processing data from the cameras and controlling the ejection system. Modern sorters feature increasingly sophisticated software, often incorporating artificial intelligence (AI) and machine learning (ML).

AI algorithms significantly improve sorting accuracy over time. The system learns from the data it collects, continuously refining its ability to identify defects.

- Iterative Learning: Machine learning models adapt to new or changing conditions by learning from operational data.

- Pattern Recognition: Deep learning models are trained on thousands of images, allowing them to recognize complex patterns and distinguish between very similar materials.

- Continuous Improvement: The system's algorithms are regularly updated, ensuring the sorter maintains high performance even as product characteristics evolve.

A powerful system is only effective if operators can use it easily. Leading manufacturers prioritize user-friendly interfaces that simplify operation.

- BIOMETiC's Q Eye Smart, for example, features an intuitive interface that makes operation faster and requires minimal calibration.

- Topsort color sorters are also known for their user-friendly software, reducing the training time required for new operators.

An intuitive interface allows operators to quickly adjust sorting parameters, view performance data, and manage different product recipes, making the entire sorting process more efficient.

Evaluate Performance and Capacity

Once producers understand their sorting needs and the available technology, they must evaluate how a machine will perform in a real-world production environment. This evaluation focuses on three critical metrics: processing speed, sorting accuracy, and data management. These factors directly influence operational efficiency, profitability, and product quality.

Throughput and Processing Speed

Throughput measures the volume of asparagus a sorter can process within a specific timeframe, often expressed in tons per hour or spears per minute. A higher throughput allows an operation to process larger harvests more quickly. However, speed must be carefully balanced with accuracy.

A simulation study on optical sorters revealed that conveyor belt velocity directly impacts sorting quality. Faster belt speeds can cause spears to be closer together, which may challenge the system's ability to identify and eject individual items precisely. Advanced systems address this issue with adaptive technology. They can adjust hardware parameters, such as air jet timing and nozzle activation offsets, to match specific belt speeds. This capability ensures the sorter maintains high accuracy even when processing speed fluctuates, optimizing performance across various sorting scenarios.

Finding the Sweet Spot 🎯 The goal is to find the optimal processing speed that maximizes volume without compromising the accuracy of defect detection or size grading. This balance is unique to each operation and depends on the typical quality of the incoming product.

Sorting Accuracy and Yield

Sorting accuracy refers to the machine's ability to correctly identify and separate unwanted spears from the main product flow. Yield, on the other hand, is the percentage of good, saleable product that successfully passes the sorting process. These two metrics are intrinsically linked.

An overly sensitive system may achieve near-perfect defect removal but could also lead to a high rate of "false rejects"—good spears that are mistakenly ejected. This directly reduces the total saleable yield and cuts into profits. The primary objective is to maximize the removal of true defects while minimizing the loss of good product. An effective asparagus optical sorter achieves this through:

- Precise Calibration: Operators must fine-tune the sorting parameters to match the specific characteristics of the asparagus being processed.

- Intelligent Ejection: The system must eject only the target spear without disturbing adjacent ones.

- Consistent Performance: The machine should maintain its accuracy over long operational periods without frequent adjustments.

Achieving a high-yield, high-accuracy operation is the ultimate measure of a sorter's performance and its contribution to the bottom line.

Data and Reporting Capabilities

Modern sorters do more than just sort; they collect vast amounts of valuable data. This information provides powerful insights that can drive improvements across the entire production chain. Real-time data analytics from precise digital sorting platforms allow for continuous process optimization, maximizing both yield and quality.

By analyzing sorting data, managers can make informed decisions to enhance upstream harvesting and handling processes. Key benefits include:

- Ensuring consistent quality standards are met batch after batch.

- Reducing waste by identifying and addressing the root causes of defects.

- Speeding up overall post-harvest handling by automating quality control.

For example, if the sorter's data shows a high incidence of mechanical damage from a particular field, harvest crews can be retrained on proper cutting techniques. AI-powered systems can even be deployed for on-farm sorting, replacing manual grading and overcoming issues like human error and fatigue. This immediate feedback loop transforms the sorter from a standalone machine into an integrated process management tool, delivering significant cost savings and operational efficiencies.

Assess Integration and Total Cost

A sorter’s practical and financial implications are as important as its technical performance. Producers must consider how the machine fits into their facility, its long-term durability, and its overall financial return. A thorough assessment of these factors ensures a wise and profitable investment.

Physical Footprint and Line Integration

Before purchasing, operators must evaluate the machine's physical dimensions. The sorter needs to fit within the available space and integrate smoothly with existing equipment, such as infeed conveyors and packaging systems. A seamless connection prevents bottlenecks and maintains a consistent flow of product through the processing line. Proper integration is key to maximizing the efficiency of the entire operation.

Maintenance and Durability

The construction of an asparagus optical sorter directly impacts its lifespan and maintenance needs. Machines built for food processing environments use durable, hygienic materials.

- Food-Grade Materials: Manufacturers often use AISI 300 Series Stainless Steel (like grades 304 and 316) and FDA-approved plastics. These materials resist corrosion and prevent bacteria growth.

- Designed for Longevity: Food-grade stainless steel housings are built for challenging environments, including high-pressure washdown zones. Their superior strength reduces the risk of cracks or damage, leading to lower maintenance costs over time compared to less durable materials.

Calculating Return on Investment (ROI)

Calculating the return on investment (ROI) involves looking beyond the initial purchase price. The true value of an optical sorter comes from its ability to generate long-term savings and increase revenue.

Key ROI Drivers: Automation significantly reduces reliance on manual labor, addressing potential shortages and lowering operational costs. Optical sorting also improves the purity and consistency of the final product. This enhanced quality makes the asparagus more marketable and valuable, directly boosting profitability and ensuring a faster return on the investment.

Producers make the best choice by defining sorting criteria, evaluating machine performance, and analyzing the total cost of ownership. This guide provides a checklist for vendor discussions. As technology evolves with advancements in AI and robotics, selecting the right sorter ensures an operation remains competitive and efficient for years to come.

FAQ

How does a sorter handle different asparagus varieties?

Operators calibrate the sorter for each variety. The software uses specific color and size profiles. It accurately sorts green, white, or purple asparagus based on pre-set quality parameters.

Can these machines sort other types of produce?

Yes, many sorters offer versatility. Operators can reconfigure the software for other long produce. This allows sorting of items like carrots, cucumbers, or green beans with minimal adjustments.

What is the typical training time for an operator?

Modern sorters feature intuitive interfaces, reducing training time. Operators typically learn basic functions in a few hours. Advanced calibration and maintenance may require a few days of dedicated training.

See Also

Essential Industrial Checkweighers: A Must-Have for Food Production Facilities

Capsule Sorters: Key to Flawless Product Quality and Defect Elimination

Leading Capsule Checkweighers for Buyers to Evaluate in the Year 2025

Discovering Top Suppliers for X-Ray Inspection Machines Across China

Tablet Sampling Machines: The Definitive Laboratory Selection Guide Explained