7 Pro-Approved Building Sealants for Any Outdoor Job

Selecting the wrong sealant invites costly water damage, rot, and failed paint jobs. Professionals often prefer a high-performance MS Polymer building sealant, such as BoPin MS-240, for its all-weather reliability on windows and siding. A proper product choice protects a home from the elements.

This guide helps homeowners and contractors select the right pro-grade sealant. The goal is completing the job correctly the first time.

Paintable Versatility vs. Ultimate Weatherproofing

Choosing the right sealant often comes down to a key trade-off. A project may require a paintable finish for aesthetic cohesion or demand absolute waterproofing above all else. Understanding the strengths of each category is critical for a successful outcome.

High-Performance Paintable Sealants

Professionals choose high-performance paintable sealants for jobs requiring a seamless, color-matched finish. These products create a durable, paintable bond on surfaces like wood trim, fiber cement, and vinyl siding. Modern advancements have led to hybrid products that eliminate old compromises.

MS Polymer sealants represent the current state-of-the-art technology. They are based on a hybrid chemistry, combining the best properties of silicone and polyurethane. Unlike traditional polyurethanes, MS Polymers are isocyanate-free, making them a safer choice for applicators. This evolution offers superior performance:

- Silicones: Excellent weather resistance but generally not paintable.

- Polyurethanes: Strong, paintable adhesion but contain isocyanates.

- MS Polymers: The best of both, offering paintability, flexibility, and a safer chemical profile.

| Sealant Type | Paintability | Typical Lifespan | Notes |

|---|---|---|---|

| Polyurethane | Good | 5-15 Years | Allows for a color-matched finish after curing. |

| MS Hybrid | Excellent | 15+ Years | Combines polyurethane's paintability with silicone's durability. |

| Advanced Latex | Excellent | 5-10 Years | Often called a "painter's caulk"; paint-ready quickly. |

100% Silicone Sealants

When a job demands maximum protection from the elements and painting is not required, 100% silicone is the undisputed champion. It is the ideal choice for sealing gaps around windows, doors, and vents on non-porous surfaces like glass, metal, and vinyl.

Note: Silicone creates an incredibly durable, flexible, and waterproof seal. Its chemical structure provides exceptional resistance to weathering, moisture, and environmental pollutants, making it perfect for high-exposure areas.

Key advantages of 100% silicone include:

- Permanent Waterproofing: It forms a non-porous barrier that effectively locks out water.

- Lasting Flexibility: The material adapts to structural movements caused by temperature changes, preventing cracks.

- UV & Temperature Resistance: It withstands extreme heat, cold, and direct sunlight without shrinking or degrading.

- Mold & Mildew Resistance: Many formulas contain fungicides, making them ideal for moisture-prone locations.

The 7 Best Outdoor Sealants for 2026

Professionals evaluate sealants based on adhesion, flexibility, and job-specific requirements. The following products represent the top choices in their respective categories for 2026, delivering reliable performance for any outdoor project.

🏆 Best Overall: BoPin MS-240 All-Weather Sealant

BoPin MS-240 earns the top spot for its exceptional versatility and cutting-edge technology. As an MS Polymer, it combines the paintability of polyurethane with the superior weather resistance of silicone. This advanced formula provides a durable, flexible seal on a wide range of building materials without the use of hazardous isocyanates. Its all-weather application capabilities make it a dependable choice for year-round projects. Applicators can use it in temperatures as low as -5°C. The sealant becomes water-ready in just 2-3 hours, achieving a full cure and maximum strength within 24-48 hours.

Primary Applications: BoPin MS-240 excels in sealing joints around windows, doors, siding, and trim. Its excellent paintability allows for a seamless, professional finish that integrates perfectly with the surrounding surfaces.

🛡️ Best for Extreme Weather: GE Supreme Silicone Window & Door

When a project demands uncompromising waterproofing and long-term durability against the elements, GE Supreme Silicone is the professional standard. This 100% silicone formula offers permanent flexibility, meaning it will not crack, shrink, or break down when exposed to severe temperature fluctuations. It forms an impenetrable barrier against water and air intrusion. The sealant also provides 10-year mold-free product protection, making it ideal for areas with high moisture.

| Attribute | Performance | Detail |

|---|---|---|

| Flexibility | Permanent | Absorbs joint movement from thermal expansion. |

| Weather Resistance | Extreme | Withstands UV radiation, ozone, and harsh weather. |

| Paintability | Not Paintable | Designed for areas where a color match is not needed. |

| Lifespan | Lifetime Guarantee | Offers a long-term, maintenance-free seal. |

Its primary limitation is that it is not paintable. Professionals reserve it for applications where its clear or stock color appearance is acceptable, such as sealing metal flashing, vents, and non-painted vinyl window frames.

🧱 Best for Concrete & Masonry: Loctite PL Polyurethane Concrete Crack & Masonry Sealant

Concrete and masonry require a sealant with exceptional toughness and adhesion. Loctite PL Polyurethane is specifically engineered for these demanding, porous surfaces. This sealant creates a durable, flexible bond that withstands harsh weather and foot traffic. It is the ideal solution for repairing cracks and filling control joints in horizontal and vertical surfaces. Its polyurethane chemistry ensures it cures to a firm, yet pliable, consistency.

This product demonstrates excellent adhesion to common masonry materials, including:

- Concrete

- Brick

- Stucco

Critical Function: By sealing cracks in driveways, foundations, and walkways, Loctite PL prevents water from penetrating the surface. This protection is vital for stopping the destructive freeze-thaw cycles that cause further damage to concrete structures.

🌲 Best for Wood Siding & Trim: DAP Dynaflex Ultra Advanced Exterior Sealant

Wood surfaces present a unique challenge due to their natural expansion and contraction with changes in temperature and humidity. DAP Dynaflex Ultra is engineered specifically for this movement. This advanced sealant provides a flexible, crack-proof seal that protects wood siding, fascia, and trim from moisture intrusion and paint failure. Its formulation ensures it adheres strongly to wood and cedar, creating a durable barrier that moves with the substrate.

The product's performance stems from its innovative WEATHER MAX Technology. This system provides exceptional, long-lasting protection against the elements.

- Lasting Flexibility: It maintains resilience in both hot and cold climates, preventing cracks and breaks.

- Crack Resistance: The formula is guaranteed not to crack, crumble, chalk, or bubble over time.

- UV Protection: It offers superior resistance to UV radiation, which prevents color fading and yellowing.

Pro Tip: DAP Dynaflex Ultra also includes a lifetime mold, mildew, and algae resistance guarantee. This feature is critical for wood applications, where trapped moisture can lead to rot and decay.

The sealant is paint-ready in just one hour, allowing contractors and homeowners to complete jobs quickly without sacrificing quality. Its ability to prevent cracks in the caulk line ensures a long-lasting, professional paint finish.

💰 Best Budget-Friendly Performer: DAP Alex Plus Acrylic Latex Caulk Plus Silicone

For general-purpose outdoor sealing on a budget, DAP Alex Plus is a trusted industry staple. Often called a "painter's caulk," this product combines the easy application and paintability of an acrylic latex with the added durability and waterproofing of silicone. It offers reliable performance for sealing gaps and joints with minimal movement, such as around trim and siding.

While it may not offer the extreme flexibility of an MS Polymer or 100% silicone, its performance far exceeds typical entry-level caulks. It provides a strong, durable seal that is ready for painting in just 30 minutes.

A key indicator of its quality is its professional certification. DAP Alex Plus exceeds ASTM C834 standards for elastomeric sealants, a specification that guarantees a certain level of performance and reliability. This makes it a dependable choice for less demanding applications where both cost and quality are important.

Its primary advantages are its low cost, fast paint-ready time, and easy water cleanup. This makes it an excellent choice for sealing small cracks and gaps before an exterior paint job.

🌿 Best Eco-Friendly Option: Ecos-TDS Air and Vapor Barrier Sealant

For projects where environmental impact and indoor air quality are top priorities, Ecos-TDS Air and Vapor Barrier Sealant is the leading choice. This product is specifically formulated to be non-toxic, containing zero VOCs (Volatile Organic Compounds), solvents, or isocyanates. It is an ideal sealant for creating airtight seals in a building's envelope without introducing harmful chemicals into the living space.

Its primary function is to stop air and vapor leakage around windows, doors, and wall penetrations. By creating a continuous, flexible membrane, it improves a home's energy efficiency and prevents moisture from entering the wall cavity.

| Feature | Specification | Benefit |

|---|---|---|

| VOC Content | Zero | Safe for indoor air quality; no off-gassing. |

| Odor | None | Ideal for use in occupied spaces. |

| Composition | Toxin-Free | Contains no hazardous isocyanates or solvents. |

| Function | Air & Vapor Barrier | Enhances energy efficiency and moisture control. |

While not designed for high-movement expansion joints, Ecos-TDS excels at its intended purpose: providing a safe, effective, and permanent air seal. Professionals choose it for green building projects and for clients sensitive to chemical odors.

💧 Best for Gutters & Flashing: OSI Gutter & Seam Sealant

Gutters and flashing demand a sealant that can withstand constant water exposure and adhere tenaciously to metal surfaces. OSI Gutter & Seam Sealant is a professional-grade product specifically engineered for these high-stakes applications. This elastomeric sealant creates a completely waterproof and weatherproof seal on common gutter materials, including aluminum, galvanized steel, and vinyl. Its formula is designed to remain flexible, accommodating the expansion and contraction of metal components caused by temperature changes.

The sealant’s robust composition allows it to perform reliably in various climates. After it has fully cured, the OSI Gutter & Seam Sealant has a specified service temperature range of 40 to 120 degrees Fahrenheit, ensuring it will not fail during hot summers or cold winters. It cures to a tough, rubbery consistency that effectively seals out water and dirt.

Key Application: This sealant excels at creating durable, watertight seals on gutter seams, end caps, and drop outlets. Its ability to bond dissimilar materials also makes it the top choice for sealing flashing around chimneys, vents, and skylights.

Professionals rely on this product for its specific capabilities in water-shedding systems. Its primary uses include:

- Sealing joints and connections in metal or vinyl gutters.

- Repairing leaks in downspouts and elbows.

- Adhering flashing to roofing, siding, and brick.

- Waterproofing overlaps in sheet metal applications.

Its specialized formula ensures long-term protection against leaks, making it an essential tool for any roofing or gutter installation project.

Choosing the Right Building Sealant for Your Job

Selecting the ideal building sealant requires a careful evaluation of the project's specific demands. Professionals consider three primary factors: joint movement, surface material, and the need for a paintable finish. A methodical approach ensures the chosen product delivers a durable, long-lasting seal.

Assessing Movement and Flexibility Needs

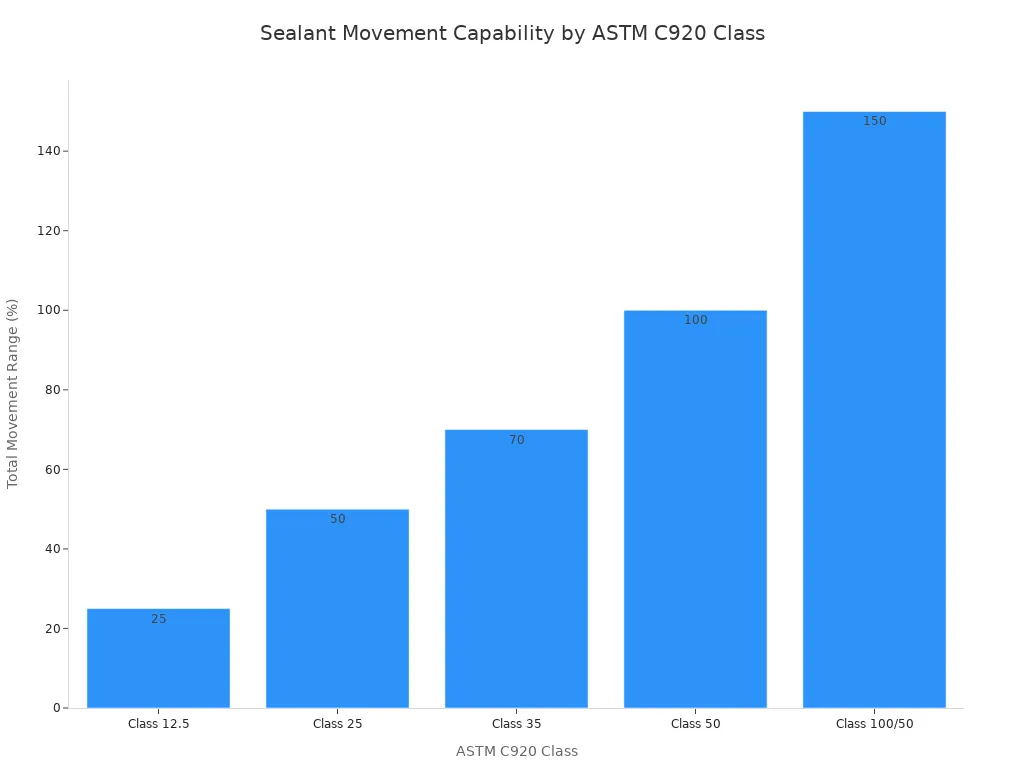

Building materials naturally expand and contract with temperature changes. A sealant must accommodate this movement to prevent failure. For example, a long concrete slab can move significantly between summer and winter, requiring a highly flexible building sealant. The industry measures this capability using the ASTM C920 standard, which classifies products based on their tested movement capacity.

- Class 12.5: Handles ±12.5% movement, suitable for low-movement interior joints.

- Class 25 & 35: Manages ±25% to ±35% movement, common for window perimeters.

- Class 50 & 100/50: Accommodates ±50% or greater movement, necessary for expansion joints and curtain walls.

Choosing a building sealant with the correct movement class prevents cracks and adhesion failure over time.

Matching Sealant to Surface Material

A sealant’s chemical formula must be compatible with the surface, or substrate, to create a strong bond. Some materials, like treated wood or certain plastics, may require primers or specialized formulas. Porous surfaces like concrete and brick need a sealant that can adhere effectively, while metal panels demand a product that can handle their high rate of thermal expansion.

Advanced hybrid sealants like MS Polymers offer excellent versatility. They bond well to a wide range of common building materials without special preparation.

| Sealant Type | Common Compatible Materials |

|---|---|

| MS Polymer | Wood, Vinyl, Fiber Cement, Metal, Masonry |

| Polyurethane | Concrete, Brick, Stucco, Wood |

| 100% Silicone | Glass, Metal, Vinyl, Tile (Non-Porous) |

| Acrylic Latex | Wood Trim, Drywall, Painted Surfaces |

Considering Paintability Requirements

For projects where aesthetics are key, paintability is a non-negotiable feature. A paintable building sealant allows for a seamless, color-matched finish on surfaces like siding, trim, and fascia. Most paintable sealants, including advanced acrylics and MS Polymers, are designed for compatibility with water-based latex or acrylic paints. In contrast, 100% silicone sealants are not paintable and are best reserved for applications where their clear or stock color is acceptable. Always check the product label to confirm paint compatibility and cure times before application.

Pro Application Tips for a Permanent Seal

Even the best sealant will fail if applied improperly. Professionals follow a precise method to ensure the product adheres correctly and creates a lasting, weatherproof barrier. These steps transform a good product into a great result.

Step 1: Prepare the Surface

Proper surface preparation is the most critical step for achieving a permanent bond. The sealant needs a clean, dry, and sound substrate to adhere to. Any contaminants will compromise the seal's integrity.

Pro Tip: For old sealant removal, a utility knife and a putty knife are essential tools. After scraping away the bulk of the old material, a specialized sealant remover can dissolve any remaining residue.

Before applying new sealant, applicators must ensure the joint is completely free of:

- Old caulk or sealant

- Dust, dirt, and debris

- Oil, grease, or wax

- Loose paint or rust

A final wipe with a solvent like isopropyl alcohol on a clean cloth removes any lingering contaminants. The surface must be completely dry before application begins.

Step 2: Cut the Tip for the Perfect Bead

The size of the sealant bead should match the size of the gap. A common mistake is cutting the nozzle tip too large, which wastes material and creates a messy joint. Professionals cut the tip at a 45-degree angle. This angled cut allows the tip to act as a smoothing tool as the bead is applied. The opening should be slightly smaller than the joint to be filled. This ensures the sealant is forced into the gap, creating a stronger bond.

Step 3: Apply with Consistent Pressure

A uniform bead is the hallmark of a professional job. Achieving this requires a steady hand and consistent pressure on the caulk gun. A high-quality gun with a smooth-piston mechanism provides superior control.

To lay a perfect bead, professionals follow a specific technique:

- Hold the caulk gun at a consistent 45-degree angle to the joint.

- Squeeze the trigger gradually to start an even flow of sealant.

- Maintain constant pressure on the trigger while moving at a steady speed.

- Push the bead into the joint rather than pulling it along the surface.

This method ensures the sealant fills the gap completely from the bottom up, eliminating air pockets and creating a solid, durable seal.

Step 4: Tool the Bead for a Pro Finish

Tooling is the final step that separates an amateur job from a professional one. This process involves smoothing the freshly applied sealant bead. It serves two critical functions. First, it creates a clean, concave profile that looks neat and sheds water effectively. Second, it forces the sealant into the joint, ensuring full contact with both surfaces for maximum adhesion. This eliminates air voids and strengthens the bond.

Applicators should tool the bead within 5-10 minutes of application, before the sealant begins to form a skin. The technique requires a light, consistent touch. The goal is to glide over the bead in one continuous motion, removing a small amount of excess material. This action shapes the sealant into a uniform, professional-looking joint.

Pro Tip: For a perfectly smooth finish, especially with sticky 100% silicone, professionals often use a tooling agent. A light mist of denatured alcohol or a specialized tooling spray on the bead and the tool prevents the sealant from sticking, allowing for an effortless glide.

Several options exist for tooling a bead. Each offers a different level of control and finish.

- Caulking Spatula: A dedicated plastic or metal tool designed to create a perfect profile.

- Wet Finger: A common method, but it can be messy and less precise.

- The Back of a Spoon: A simple household item that can create a consistent concave shape.

Proper tooling is the finishing touch that guarantees a durable, watertight, and aesthetically pleasing seal. It transforms a simple bead of caulk into a high-performance barrier that protects the structure for years.

A project's specific needs dictate the final product choice. Professionals select advanced polymer sealants for jobs requiring paintable versatility. They trust 100% silicone for ultimate weatherproofing on unpainted surfaces. Investing in a quality building sealant and using the correct application technique is the key to protecting a home from the elements. This combination ensures a durable, long-lasting result.

Seal it right, and you'll only have to seal it once.

FAQ

What is the difference between caulk and sealant?

Professionals distinguish the two by flexibility. Sealants are highly elastic materials designed to accommodate significant joint movement. Caulks are typically more rigid, making them suitable for filling static gaps and cracks. Sealants offer superior weather resistance for dynamic joints.

How long does sealant take to cure?

Cure times depend on the sealant type, temperature, and humidity. Many products are water-ready in a few hours. A full cure, where the sealant reaches maximum strength, can take 24 hours to several days. Always check the manufacturer's specific instructions.

Can applicators apply new sealant over old sealant?

No. Professionals never apply new sealant over old material. The new product will not bond correctly to the old, failing sealant, leading to a weak seal. Complete removal of the old bead is essential for creating a durable, long-lasting repair.

Why is 100% silicone not paintable?

The surface of cured silicone is extremely smooth and non-porous. This low surface energy prevents paint from forming a proper bond. Paint will bead up and easily peel or flake off. Choose a paintable MS Polymer or advanced latex for color-matched areas.

See Also

Silicone Sealant: The Unsung Hero of Modern Home Construction and Decor

Fortifying Doors and Hinges: Protecting Homes from Wildfires and Floods

Leading Precoating Materials: Enhancing Filtration System Performance for 2025

Homeowner's Guide: Perfectly Matching Hinge Finishes with Door Hardware Aesthetics

Essential Safety Practices for Secure Nitric Acid Storage and Handling