Top 5 American-Made Pellet Mills for Your Small Business

Investing in American-made equipment provides businesses with superior quality and domestic support. The U.S. biomass pellets market continues its strong expansion. Market data from 2024 highlights this upward trend.

| Metric | Value |

|---|---|

| Market Valuation (End of 2024) | US$ 1,527.8 million |

| Market Volume Growth (2024) | 5.1% year over year |

A reliable pellet mill machine is essential for capitalizing on this growth. The top American-made models for small businesses include:

- Buskirk Engineering MILL-10

- CPM 3000 Series

- Freedom Equipment F-Series

- K-Pellet (K-Machine) KP150

- CME MILL-10

Key Takeaways

- The U.S. biomass pellets market is growing. This offers good chances for small businesses.

- Choosing an American-made pellet mill gives you good quality and local support.

- Match your pellet mill to your needs. Consider your raw material, how much you want to make, and your space.

- The die and rollers are very important. They affect how well the machine works and the quality of your pellets.

- Regular care keeps your pellet mill working well. Check parts often and keep them clean.

In-Depth Reviews of the Top 5 Pellet Mills

This section provides a detailed analysis of each model. We examine their performance, features, and ideal applications to help you make an informed decision for your business.

1. Buskirk Engineering MILL-10

The Buskirk Engineering MILL-10 stands out as a premier choice for small businesses and startups entering the pellet production market. Its design prioritizes versatility and ease of use. This makes it an excellent all-around performer for operators who may be new to pelletizing. The machine capably processes a wide range of biomass materials, from wood chips to agricultural waste.

Key attributes of the MILL-10 include:

- Compact Footprint: The unit requires minimal floor space, making it suitable for smaller workshops or facilities.

- Material Flexibility: It effectively handles various raw materials with simple adjustments, offering businesses operational agility.

- User-Friendly Operation: Buskirk designs its equipment for straightforward setup and maintenance, reducing the learning curve for new teams.

Best For: Small businesses and entrepreneurs needing a reliable, versatile, and cost-effective entry point into pellet production. Its adaptability is perfect for testing different feedstocks.

2. CPM 3000 Series

For businesses ready to scale up production, the CPM 3000 Series offers "Powerful pelleting in a smaller package." This series replaces the older CPM Century line with a modern, rugged design built for demanding, continuous operation. Its engineering focuses on efficiency. A single motor and a positive direct gear drive achieve 98% power transfer, which reduces energy loss and minimizes downtime. The 3000 Series serves diverse industries, including commercial animal feed, pet food, and industrial densification.

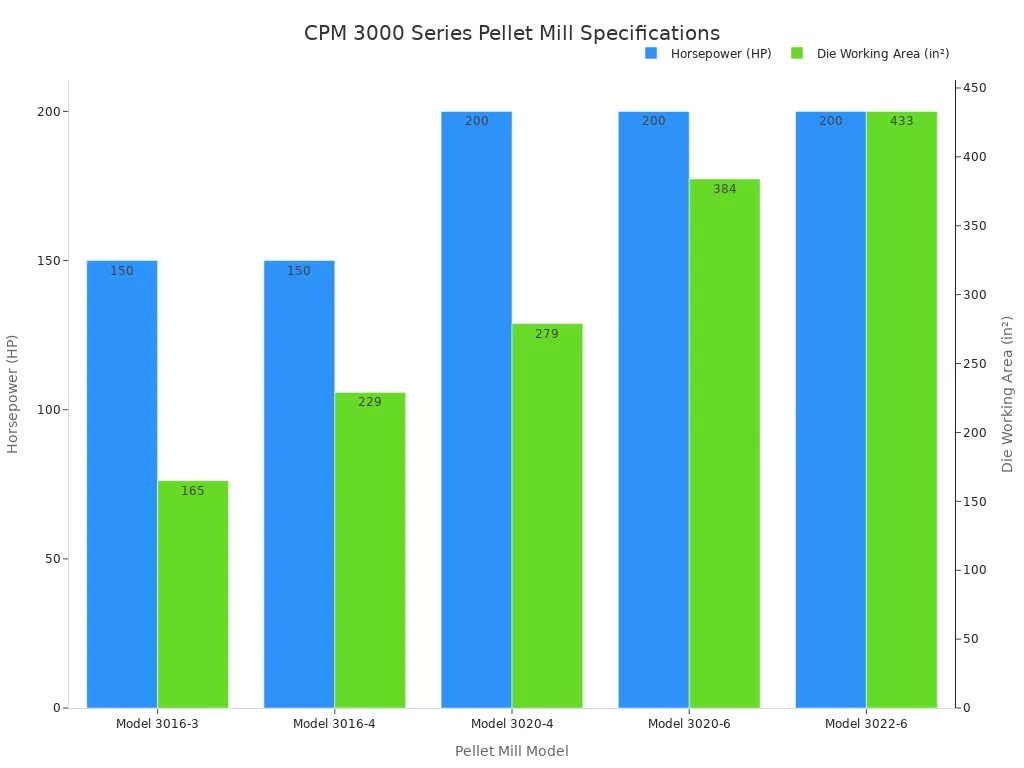

The series provides several configurations to match specific output needs. A modular gearbox accepts a wide range of die sizes, from 16 to 22 inches.

| Model | Horsepower | Die Working Area | Key Options |

|---|---|---|---|

| 3016-3 | 150 HP | 165 in² | Enforcer |

| 3016-4 | 150 HP | 229 in² | Enforcer |

| 3020-4 | 200 HP | 279 in² | Enforcer, RSM |

| 3020-6 | 200 HP | 384 in² | Lineator, Enforcer, RSM |

| 3022-6 | 200 HP | 433 in² | Lineator, Enforcer, RSM |

Advanced features are available on select models to enhance performance and simplify maintenance. These options include:

- Splash lubrication for consistent gear protection.

- Remote roll adjusting (lineator) for precise control.

- Roll speed measurement (RSM) for process optimization.

Pricing information requires direct contact with a CPM representative. The company also offers refurbished units with a guarantee, providing a potential cost-saving alternative for budget-conscious buyers.

Best For: Growing businesses that require high-volume, continuous production and industrial-grade durability. Its efficiency and robust build support demanding operational schedules.

3. Freedom Equipment F-Series

Freedom Equipment carves out a unique space in the market by combining quality machinery with exceptional customer support. While the F-Series mills are known for their robust construction, the company’s reputation for service excellence is a major selling point. Customer testimonials frequently praise the company for its "great customer service" and "prompt delivery."

This focus makes their F-Series pellet mill machine an attractive option for businesses that value a seamless procurement process and reliable post-sale support. The company demonstrates a clear commitment to client satisfaction.

One customer noted a proactive response from the company to resolve an issue: "I'm going to call you to resolve this, I want to make sure you have a 5-star experience... Let me make this right!"

This level of attentiveness provides peace of mind. Buyers can trust that they are investing in a partnership, not just a piece of equipment. The F-Series itself is built for durability and consistent performance, making it a solid workhorse for small to medium-sized operations.

Best For: Business owners who prioritize a smooth purchasing experience, fast shipment times, and a strong, supportive relationship with their equipment supplier.

4. K-Pellet (K-Machine) KP150

K-Machine builds the KP150 for precision and durability. This model appeals to operators who require consistent performance with specific or challenging feedstocks. The KP150 is not a generalist machine. It is a specialist tool engineered for reliability in dedicated production environments. Its robust construction minimizes vibration and wear, which translates to a longer operational lifespan and lower maintenance costs over time.

Key characteristics of the KP150 include:

- Heavy-Duty Build: The machine features a reinforced frame and high-quality components designed to withstand the rigors of continuous use.

- Precision Engineering: Its die and roller assembly is manufactured to tight tolerances. This ensures uniform pellet density and quality, which is critical for specialized applications like animal feed or premium biofuels.

- Simplified Mechanics: The design prioritizes mechanical reliability over complex electronic controls, making it easier to service and troubleshoot for mechanically inclined teams.

This Pellet Mill Machine delivers consistent pellet quality from a stable, powerful platform. It is an excellent choice for businesses that have already identified a primary feedstock and need a machine to process it efficiently day after day.

Best For: Businesses with a defined production focus, such as a single type of animal feed or biomass, that value mechanical robustness and consistent output over operational flexibility.

5. CME MILL-10

Colorado Mill Equipment (CME) positions the CME MILL-10 as a highly accessible, American-made entry point for non-wood pelletizing. This machine is specifically engineered for a range of softer materials. Its specifications make it a strong contender for agricultural businesses and specialty producers. With a price point of $7,900.00 and current in-stock availability, it presents a strong value proposition for new operations needing to get started quickly.

The unit runs on a 10 HP, 3-phase motor and offers a variable production capacity to match different operational scales.

| Specification/Material | Detail |

|---|---|

| Motor | 10 HP, 3-phase |

| Production Capacity | 80 to 600 lbs per hour |

| Die Inner Diameter | 8” Flat |

| Compatible Materials | Alfalfa, Corn, Hemp, Oats, Plastics, Poultry Litter, Soybean Meal, Fertilizer |

The CME MILL-10 is a capable Pellet Mill Machine for its intended applications. Its focused design ensures efficiency when processing the listed compatible materials.

⚠️ Important Note: The manufacturer explicitly states this model is not designed for processing wood. Businesses planning to produce wood pellets should consider other models.

Best For: Farms, feed producers, and specialty manufacturers focusing on non-wood materials like hemp, alfalfa, or fertilizers who need a cost-effective and readily available machine.

At-a-Glance: Comparing the Top 5 Models

Choosing the right equipment requires a clear comparison of each model's strengths. This section consolidates the key details of the top five American-made mills. It allows for a direct, side-by-side evaluation to help you identify the best fit for your business objectives.

Model Comparison Table

The table below summarizes each Pellet Mill Machine, highlighting its ideal application, standout feature, and typical power range. Use this as a quick reference guide to narrow down your options based on your specific production needs.

| Model | Best For | Key Feature | Power Range (HP) |

|---|---|---|---|

| Buskirk MILL-10 | Startups & versatile use | Compact footprint, material flexibility | 10 HP |

| CPM 3000 Series | High-volume, continuous operation | Direct gear drive, industrial durability | 150 - 200 HP |

| Freedom F-Series | Businesses prioritizing support | Exceptional customer service | Varies |

| K-Pellet KP150 | Specialized, consistent production | Heavy-duty, precision engineering | Varies |

| CME MILL-10 | Non-wood materials (e.g., hemp) | Cost-effective, focused application | 10 HP |

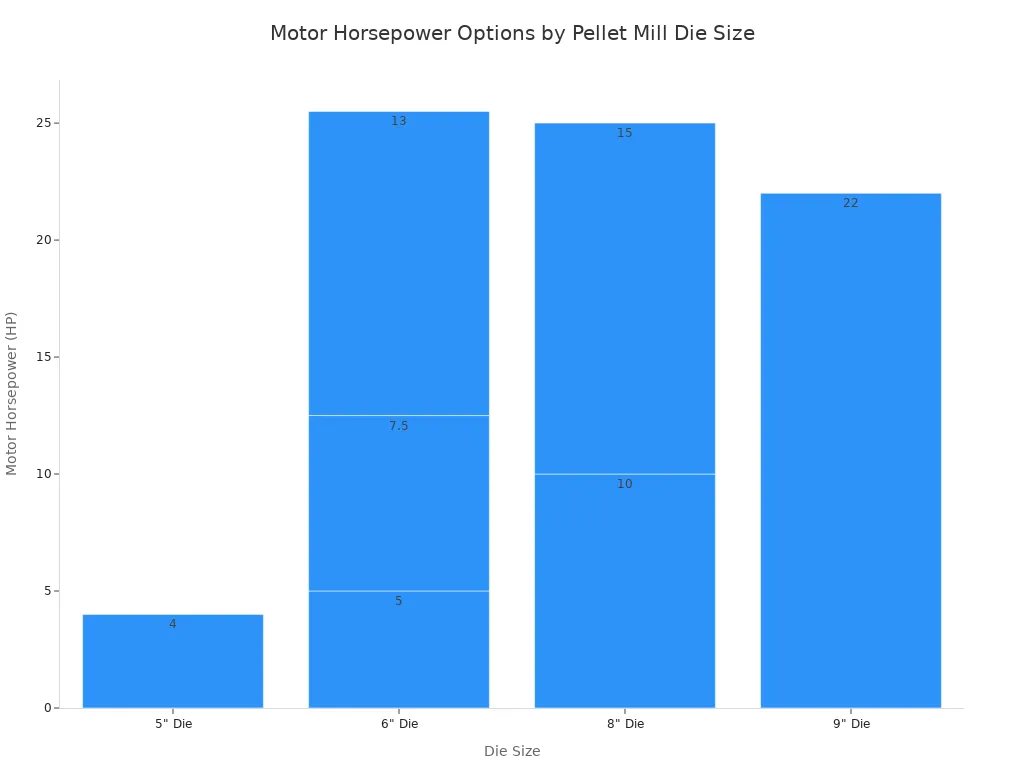

💡 Pro Tip: The horsepower (HP) of a mill's motor is a critical factor. It directly impacts production capacity and the types of materials you can process. A higher horsepower generally allows for larger die sizes and greater output.

Motor power requirements often scale with the die size of the machine. Smaller dies may only need 4-10 HP, while larger, industrial-scale units demand significantly more power. Matching the motor to your operational goals ensures efficiency and prevents equipment strain.

This visual comparison shows a clear trend. Businesses must assess their power availability and production targets when selecting a model. An underpowered machine will struggle, while an overpowered one represents an unnecessary expense.

Key Factors for Your Pellet Mill Machine

Selecting the right equipment involves more than comparing models. A business must analyze its specific operational context. Key considerations include the type of raw material, production volume goals, and facility limitations. A thorough assessment of these factors ensures the chosen Pellet Mill Machine aligns with your business needs.

Assess Your Raw Material

The type and condition of your feedstock directly influence mill performance and pellet quality. Different materials have unique properties. A wide variety of biomass can be pelletized.

- Wood and Forestry Waste: Sawdust is an ideal material due to its fine particle size. Wood chips, shavings, and leaves are also excellent feedstocks, though some may require crushing.

- Agricultural Residues: Materials like rice husk, corn straw, and alfalfa are abundant and suitable for pelletizing. They provide a great alternative for businesses without access to forestry products.

- Energy Crops: Grasses such as miscanthus and switchgrass are grown specifically for biomass. They offer high yields and efficient processing.

The moisture content of your raw material is critical. For optimal results, most materials should have a moisture level between 10% and 15%. This range ensures proper compression and durable pellets. However, some materials like rice straw produce high-strength pellets at 10% to 14% moisture.

Calculate Your Capacity Needs

A clear understanding of your production targets prevents over-investing or buying an undersized machine. Businesses can calculate their needs with a simple process.

- Estimate Your Target Volume: First, determine the daily or monthly quantity of pellets your operation requires.

- Define Your Operating Hours: Decide how many hours per day the machine will run.

- Calculate Hourly Rate: Divide the target daily volume by the number of operating hours. This gives you the required hourly production capacity.

For example, small farms or local feed producers often find that a machine with a capacity of 100–500 kg/hr meets their needs effectively.

Check Power and Space Requirements

A pellet mill machine is a significant piece of industrial equipment with specific utility needs. Before purchasing, confirm your facility can support the machine. Check the voltage and phase requirements of any model you consider. Many manufacturers can customize motors to match regional electrical standards. While larger units require 3-phase power, some smaller models can operate on single-phase electricity, a key benefit for workshops or garages. Also, review the machine's footprint to ensure it fits within your available floor space.

Understand Die and Roller Types

The die and rollers are the heart of any pellet mill machine. Their design and condition directly determine production efficiency and final pellet quality. The precision and material quality of these components are critical for optimal performance.

Rollers compress the raw material and force it through the die. The design of the roller shell significantly impacts the entire process.

- Specialized roller designs can reduce overall energy consumption.

- Textured surfaces and increased surface area decrease friction. This allows for tighter pressing and creates stronger, better-bonded pellets.

- High-quality alloy steel extends the life of the rollers and ensures consistent pellet sizes.

- Proper alignment of the rollers with the die minimizes energy loss and prevents uneven wear on the components.

The die is a metal plate with holes that shapes the compressed material into uniform pellets. The lifespan of both dies and rollers depends on several manufacturing and operational factors.

💡 Maximizing Component Life Abrasive materials and high-fiber feedstocks like layer feed accelerate wear. In contrast, a small amount of fat (1.5-4%) in the formulation acts as a lubricant, reducing friction. An operator's skill is also vital. Regular checks of the die-roller gap and cleaning magnets can dramatically extend the life of these critical parts. Manufacturing quality, especially the use of high-chrome steel and proper heat treatment, provides the foundation for durability.

Choosing the right die and roller combination for a specific feedstock is essential. This ensures consistent pellet quality, improves feed conversion for animals, and boosts overall productivity for the business.

The Buskirk Engineering MILL-10 offers the best balance of performance and value for most small businesses needing a versatile entry point in 2025. For operations with higher volume needs or requiring robust, continuous operation, the CPM 3000 Series is the superior investment.

💡 Final Takeaway: Choosing an American-made pellet mill machine provides businesses with quality construction and reliable domestic support, securing a strong foundation for future growth.

FAQ

What is the difference between a flat die and a ring die mill?

A flat die mill uses a stationary, horizontal die with rollers pressing material downward. It is common in smaller machines like the CME MILL-10. A ring die mill uses a vertical, rotating die with internal rollers, offering higher capacity and efficiency for industrial use like the CPM 3000.

How much maintenance does a pellet mill require?

Regular maintenance is crucial for performance. Operators should perform daily checks on the die and rollers for wear. Routine tasks also include lubricating bearings and cleaning magnets to remove metal debris. This extends the life of critical components and ensures consistent pellet quality.

Can one mill process both wood and agricultural feed?

Some versatile models, like the Buskirk MILL-10, can handle various materials. However, machines are often optimized for specific feedstocks. A mill designed for softer agricultural materials may not handle dense wood. Businesses should select a mill based on their primary raw material for best results.

What other equipment is needed for pellet production?

A complete production line requires more than just the pellet mill. Key equipment includes a hammer mill for reducing material size, a dryer to control moisture content, and a cooler to harden the finished pellets. Conveyors are also necessary to move material between stages.

See Also

Essential Industrial Vacuum Cleaners: Top 6 Picks for Your Business

Choosing the Best Nameplate Supplier: Key Factors for 2025 Success

Indispensable Industrial Checkweighers: The Top 3 for Food Plants

Silent Versus Open Frame 6kW Diesel Generators: Which One Fits Your Needs?

Ampoule Filling Production Lines: A Comprehensive Manufacturer Comparison Guide