Berries Optical Sorter Innovations for 2026

The global specialty fruits market, reaching USD 128.8 billion in 2024, faces significant challenges. Post-harvest losses can reach 45% for delicate crops like strawberries, impacting profitability. A modern berries optical sorter directly addresses this waste. It uses advanced AI and hyperspectral imaging to assess internal quality, enhancing pack-out and efficiency.

AI and Machine Learning: The New Brains of Sorting

Artificial intelligence (AI) and machine learning (ML) represent the new cognitive engine powering the next generation of sorting equipment. These advanced systems move far beyond basic color and size grading. They introduce an element of learning and adaptation. The sorter's "brain" continuously improves its performance, making decisions with a level of speed and nuance that is impossible for human inspectors. This intelligence is the key to unlocking unprecedented levels of quality control and efficiency.

Predictive Defect Analysis

The most significant leap forward in AI-driven sorting is predictive defect analysis. This technology allows sorters to identify issues before they become visible to the naked eye. AI models analyze subtle data points from images to forecast the development of defects. This proactive approach is a game-changer for extending shelf life and reducing waste.

Leading technology firms are already deploying these solutions.

- Intello Labs uses computer vision and AI for precise food quality assessment.

- Their Intello FruitSort machine employs 360-degree cameras to detect a wide range of defects.

- The Intello Sort system then physically segregates produce based on size, color, and quality for different supply chain needs.

These AI systems can identify the earliest signs of common berry issues. They detect microscopic problems that signal future decay, giving processors a critical advantage. Specific defects that AI can predict include:

- Dehydration and shrivel

- Micro-cracks and stem tears

- Incipient mold growth

- Mummy berry infection sites and disease progression

Deep learning models, such as Convolutional Neural Networks (CNNs), are vastly superior to older machine vision algorithms. They achieve this through several key advantages:

- Speed: Models like ResNet can classify a berry in as little as 5.2 milliseconds, dramatically outpacing manual sorting.

- Accuracy: Deep learning minimizes false positives by understanding context, ensuring good fruit is not wasted.

- Data Integration: CNNs uniquely process information across multiple spectral and spatial dimensions, a task where traditional algorithms struggle.

Case in Point: A real-world case study tested a YOLOv8 deep learning model for strawberry defect detection. The system achieved a mean average precision (mAP) of 0.945. It proved especially effective at identifying subtle Class C defects that human inspectors often miss. This demonstrates how AI integration directly improves quality control and reduces waste in a commercial setting.

Self-Optimizing Sorting Parameters

A modern berries optical sorter no longer requires constant manual calibration. AI-powered systems now feature self-optimizing parameters that automatically adjust to changing conditions. The machine learns from the fruit it processes and refines its sorting criteria in real time. This ensures peak performance whether sorting different berry varieties or handling fruit from a new harvest.

These intelligent systems use a combination of powerful imaging and exclusive algorithms to deliver consistent grading. Key features enabling this autonomy include:

- AI-Driven Seasonal Compensation: Algorithms automatically adjust for natural variations in berry size, color, and defect patterns that occur between different growing seasons.

- Rapid Variety Changeover: The system uses specialized presets for strawberries, blueberries, and raspberries, drastically cutting the downtime needed to switch between product runs.

- Continuous Self-Learning: The AI records grading data on-site, constantly improving its ability to classify different defects and making system adjustments simple for operators.

For example, a machine like the Magnus sorter uses gentle O-shaped belts and minimal drop heights specifically for delicate raspberries. At the same time, its AI interprets data from cameras and lasers to sort by internal and external qualities. This fusion of intelligent software and specialized hardware allows a single production line to handle diverse products with optimal precision and care. The system learns the unique characteristics of each berry type, ensuring that sorting is both accurate and gentle.

Advanced Imaging in the Modern Berries Optical Sorter

If AI is the brain of a modern sorter, then advanced imaging systems are its superhuman eyes. By 2026, the technology moves far beyond simple color cameras. A modern berries optical sorter uses a fusion of sensors to see the invisible. Optical sensors, high-speed cameras, and sophisticated algorithms work together on the conveyor line. High-speed cameras capture detailed images of each fruit from multiple angles for comprehensive analysis. This allows for the rapid, non-destructive analysis of attributes like color, size, shape, and surface defects, providing a significant improvement over manual sorting. These systems build a complete digital profile of every single berry, assessing qualities both inside and out.

Hyperspectral Imaging for Internal Quality

The most revolutionary imaging technology is hyperspectral imaging (HSI). While a standard camera sees three colors (red, green, and blue), an HSI sensor captures data across hundreds of narrow wavelength bands. This process creates a unique spectral signature, or "fingerprint," for each berry. This fingerprint reveals the berry's chemical composition without ever touching it.

Processors use this data to measure key indicators of taste and quality that were previously only discoverable through destructive lab testing. AI models analyze the spectral data to quantify these internal attributes in real time.

How It Works: A model can correlate a berry's spectral reflectance at a specific wavelength, like 570 nm, to its acidity. For example, a simplified model might look like

PH = 1.515 * R570 - 0.2733 + 1.434. Similarly, sugar content (Brix) can be accurately predicted by analyzing other spectral bands. Validation tests show these models achieve high accuracy, with predicted values closely matching those from traditional lab measurements.

This technology allows processors to sort berries based on consumer experience, ensuring every clamshell is filled with fruit that meets a specific flavor profile.

| Internal Quality Metric | How HSI Measures It | Benefit for Processors and Consumers |

|---|---|---|

| Brix (Sugar Content) | Correlates spectral data to sugar concentration. | Guarantees consistent sweetness and flavor. |

| Acidity (pH) | Analyzes light reflectance to determine acid levels. | Ensures a balanced taste profile, avoiding overly tart fruit. |

| Firmness/Turgor | Detects subtle changes in light scatter related to water content. | Reduces mushy berries in the final pack and improves shelf life. |

| Dry Matter | Measures the berry's solid content versus its water content. | Identifies more robust, flavor-dense fruit. |

3D and Structured-Light Scanning

While HSI looks inside the berry, 3D and structured-light scanning create a perfect topographical map of its exterior. This technology overcomes the limitations of 2D cameras, which can misinterpret size and shape. The system projects a pattern of harmless light (often infrared) onto the berry. Cameras then analyze how this pattern deforms across the berry's surface to calculate its exact dimensions, volume, and shape.

This detailed 3D model enables far more precise grading for:

- Accurate Sizing: The sorter can categorize blueberries by precise volume, not just diameter. This ensures uniformity in packaging for a premium look and feel.

- Shape Defect Detection: It instantly identifies misshapen, creased, or compressed berries that 2D cameras might miss.

- Damage Analysis: The system can spot subtle flat spots or indentations caused by impacts during harvesting or transport.

A Leap in Precision: 3D scanning allows a sorter to differentiate between a large, round berry and a long, thin berry of the same weight. This volumetric data is critical for high-value export markets where visual perfection and packaging consistency are paramount.

Chlorophyll Fluorescence for Ripeness

Chlorophyll fluorescence (CF) is an advanced technique that offers a direct biological measurement of ripeness. As a berry ripens, the chlorophyll in its skin breaks down. This natural process emits a tiny, invisible glow of light when stimulated by a specific light source on the sorter. Highly sensitive sensors measure the intensity of this fluorescence.

A strong fluorescence signal indicates high levels of chlorophyll, meaning the berry is under-ripe. A weak or non-existent signal means the chlorophyll has degraded, and the berry is ripe or even over-ripe.

This method is superior to simple color sorting for several reasons:

- Objective Measurement: It measures a biological process, not just surface color, which can be affected by sun exposure or variety.

- Detects Uneven Ripening: It can identify berries that are colored on one side but still green and unripe on the other.

- Optimizes Harvest Timing: Data from CF can inform growers about the overall ripeness of a batch, helping to optimize picking schedules.

By using chlorophyll fluorescence, processors can guarantee that every berry in the final package has reached its peak flavor and texture, dramatically improving consumer satisfaction.

Gentle Handling and Mechanical Precision

An optical sorter's advanced imaging and AI are only effective if the mechanical handling system preserves the fruit's quality. By 2026, innovations in gentle handling are just as critical as the sorter's digital brain. The focus shifts to minimizing impact at every stage, from ejection to final packaging. This mechanical precision ensures that the delicate nature of berries is respected throughout the sorting process, preventing bruising and preserving value.

Soft Robotic Ejection Systems

Traditional sorters often use puffs of air to eject defective fruit, which can cause bruising. The future lies in soft robotic systems that handle berries with unparalleled gentleness. These systems use compliant materials and intelligent designs to mimic the softness of a human touch.

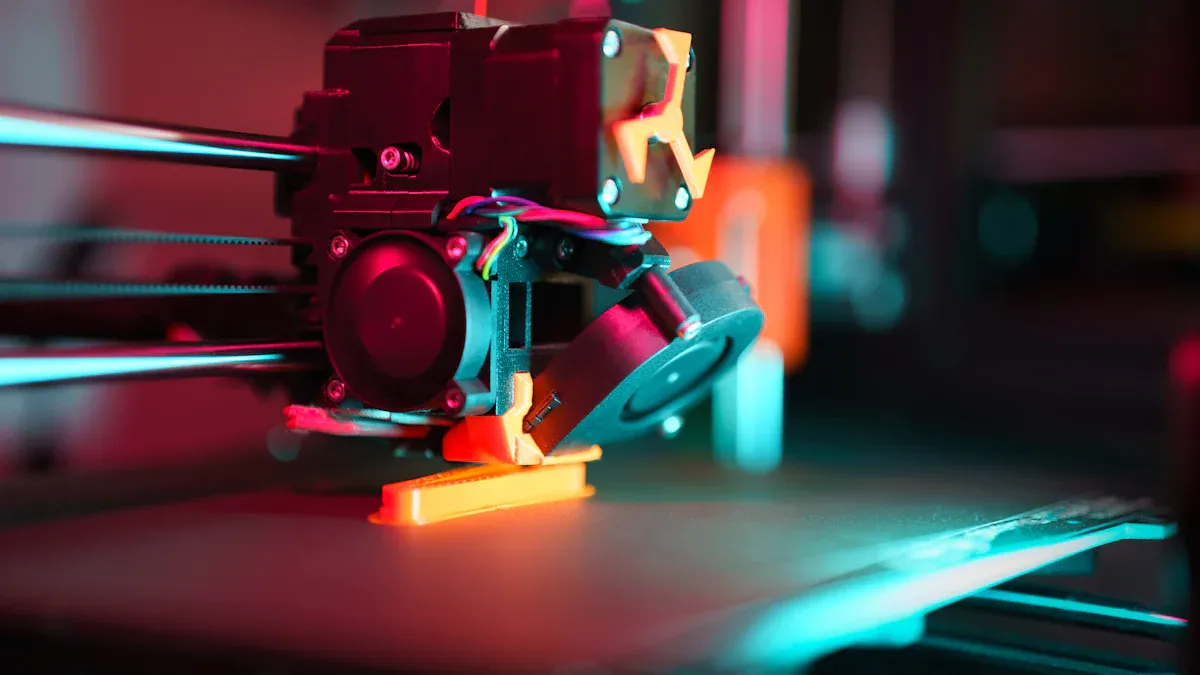

Engineers design these soft ejectors using materials like thermoplastic elastomers (TPEs) and silicone. These materials are ideal for 3D printing complex, flexible structures. The designs often feature an enveloping grasp rather than a pinching motion. This approach distributes pressure evenly across the berry's surface. A gripper might use a bellows-like actuator to gently surround and lift a berry, applying force as low as 0.5 Newtons. This method drastically reduces physical damage, such as red drupelet reversion (RDR) in blackberries, ensuring that only truly defective fruit is removed without harming acceptable ones.

Automated Infeed and Distribution

After sorting, the journey is not over. Automated infeed and distribution systems create a seamless, efficient flow from the sorter to the packaging line. These systems replace manual handling, which reduces labor costs and minimizes human error. Automation is key to maintaining the high quality established by the berries optical sorter.

Automated distribution offers several key advantages for processors:

- Enhanced Efficiency: Systems can operate 24/7, handling high volumes of fruit rapidly and increasing overall throughput.

- Reduced Labor Costs: Automation minimizes the need for manual sorting and handling, freeing up employees for more strategic, value-added tasks.

- Improved Accuracy: Technologies like RFID tags and barcode scanners ensure berries are routed to the correct packaging or processing lines, reducing costly errors and improving customer satisfaction.

By integrating these systems, processors can create a highly efficient and scalable operation. This streamlined workflow reduces operational costs, optimizes order fulfillment, and ensures that the perfectly sorted berries reach consumers in pristine condition.

Industry 4.0: Data, Analytics, and Connectivity

Modern sorting equipment transcends mechanical function, evolving into connected data hubs central to the Industry 4.0 framework. The integration with Internet of Things (IoT) platforms enables real-time monitoring and diagnostics. This digital transformation improves operational efficiency for processors and aligns with broader trends of automation and sustainability in the food market. These systems provide a constant stream of actionable intelligence, turning the sorting line into a strategic asset.

Real-Time Yield and Quality Reporting

Sorters now generate valuable live data on fruit quality and processing efficiency. Each piece of fruit is evaluated for key attributes, providing a detailed overview of the entire batch.

- Size and Shape: Systems confirm repeatability within ±0.5mm for precise size grading.

- Color and Texture: Ripeness and firmness are assessed for consistency.

- Defect Types: The presence of mold, contaminants, or damage is logged with up to 98% accuracy.

This real-time feedback empowers growers to optimize every load. By analyzing quality reports directly from the line, they can make immediate adjustments to harvesting practices, reduce waste, and maximize their marketable yield. The focus shifts from simple quantity to verifiable quality.

Enhanced Traceability with Blockchain

Blockchain technology offers a revolutionary approach to supply chain transparency. It creates an immutable, distributed ledger that logs every transaction from the farm to the consumer. This system allows all stakeholders to contribute information, achieving comprehensive visibility. Data security is enhanced, as the decentralized nature of blockchain inherently protects against tampering and unauthorized access.

This capability is crucial for food safety and rapid recalls. Pilot programs have demonstrated remarkable results.

- Walmart and IBM used blockchain to trace mangoes from Mexico to the US.

- The system reduced tracing time from nearly a week to just 2.2 seconds.

By integrating data from IoT devices, blockchain provides a verifiable record of a berry's journey, ensuring its origin and quality are never in doubt.

The future of berry sorting in 2026 is defined by the integration of AI-powered analysis, non-destructive internal quality measurement, and sophisticated robotic handling. Adopting these innovations is crucial for achieving superior product quality and profitability. However, growers face several barriers when considering a new berries optical sorter.

- High Costs: The initial investment and unclear return on investment can be a significant hurdle.

- Integration Challenges: New technology must work seamlessly with existing farm systems without causing downtime.

- Lack of Agricultural Understanding: Vendors must demonstrate they understand the real-world demands and limitations of farming operations.

FAQ

How does a modern berries optical sorter improve profitability?

It boosts pack-out quality and cuts food waste. Automation also lowers labor costs, directly increasing profit margins and providing a faster return on investment.

Can these new sorters integrate with existing production lines?

Yes, manufacturers design modern sorters for seamless integration. They use modular components and standard data protocols to connect with existing equipment, minimizing operational downtime.

What is the main driver for adopting these innovations?

Consumer demand for consistent, high-quality fruit is the primary driver. These technologies help growers meet strict retail standards and gain a competitive advantage in the market.

See Also

Essential Folder Gluer Innovations for Modern 2025 Carton Production Lines

Top Capsule Checkweighers: Key Considerations for Buyers in the Year 2025

Capsule Sorters Explained: Vital for Effective Defect Elimination in Production

Three Essential Industrial Checkweighers: A Must-Have for Every Food Processing Plant

Significant Updates: Understanding Bearing Box Freight Classification Changes and Impacts