ASTM A815 2507 Duplex Elbows The Ultimate Guide for Harsh Environments

In demanding industrial settings, piping system failure is not an option. Standard components like 904L Stainless Steel Pipe Fittings often fall short under extreme conditions. The ASTM A815 2507 Duplex Steel Elbow, however, delivers unparalleled performance where other materials fail. The market for duplex steel pipes reflects this, with projections showing a growth of USD 166.6 million by 2029. This elbow's unique composition provides the ultimate defense against severe corrosion and high mechanical stress, ensuring system integrity and operational safety.

Key Takeaways

- ASTM A815 2507 Duplex Elbows are very strong. They resist rust and damage in tough places.

- This steel has a special mix of materials. This mix helps it fight rust better than other steels.

- These elbows work well in many industries. This includes oil, gas, and water plants.

- Choosing these elbows saves money over time. They last longer and need fewer repairs.

- Proper welding and care are important. This keeps the elbows working their best.

What is 2507 Super Duplex Steel?

2507 Super Duplex, designated as UNS S32750, is a high-alloy stainless steel engineered for the most demanding applications. Its composition, rich in chromium, molybdenum, and nitrogen, gives it exceptional strength and corrosion resistance. Modern manufacturing relies on advanced methods to produce this robust material, ensuring consistent quality and performance. Key production techniques include:

- Laser Powder-Directed Energy Deposition (LP-DED)

- Selective Laser Melting (SLM)

- Cold Metal Transfer (CMT) Wire and Arc Additive Manufacturing (WAAM)

These processes create the foundation for a material built to withstand extreme conditions.

The ASTM A815 Standard for Fittings

The ASTM A815 specification governs wrought ferritic, ferritic/austenitic, and martensitic stainless steel fittings. This standard is critical because it mandates the requirements for manufacturing, chemical composition, mechanical properties, and testing. An ASTM A815 2507 Duplex Steel Elbow must adhere to these strict guidelines. This ensures every fitting provides the reliability and safety necessary for high-stakes industrial systems.

The Balanced Duplex Microstructure

The term "duplex" refers to the steel's two-phase microstructure, which contains a balanced mix of austenite and ferrite. An ideal 50:50 ratio optimizes the material's performance. This unique structure delivers significant advantages:

- It combines the beneficial properties of both austenitic and ferritic steels.

- The two-phase structure inhibits grain growth during heat treatment, which increases overall strength and toughness.

- It provides a superior combination of mechanical and corrosion resistance compared to single-phase stainless steels.

Defining Material Properties

A key metric for evaluating corrosion resistance is the Pitting Resistance Equivalent Number (PREN). This value predicts a material's ability to resist localized pitting corrosion, especially in chloride-heavy environments like seawater. 2507 Super Duplex steel excels in this area.

| Steel Grade | PREn Value |

|---|---|

| 2507 Super Duplex | > 40 |

💡 Note: Materials with a PREN value greater than 40 are considered essential for safe and stable operation in offshore and marine service, making 2507 the premier choice for these environments.

Why Choose an ASTM A815 2507 Duplex Steel Elbow?

Selecting the right component is crucial for the safety and efficiency of any high-stress piping system. An ASTM A815 2507 Duplex Steel Elbow offers a combination of properties that make it the definitive choice for harsh environments. Its advanced engineering provides solutions where conventional materials would quickly degrade and fail.

Unmatched Corrosion Resistance

The primary advantage of 2507 super duplex steel is its exceptional ability to resist corrosion. Its high chromium, molybdenum, and nitrogen content provides a robust defense against various corrosive agents. In chloride-rich environments, 2507 super duplex stainless steel is superior to both 904L and 2205 grades. It demonstrates excellent resistance to:

- Chloride pitting and crevice corrosion

- Chloride stress corrosion cracking (SCC)

- General corrosion in acidic solutions

This material also excels in challenging chemical processing environments. For instance, 2507 shows superior corrosion resistance in sulfuric acid mixed with chloride ions compared to 904L. It can even operate in dilute hydrochloric acid, an environment where 316L steel is unsuitable due to its high susceptibility to corrosion.

Application Insight: The NACE MR0175/ISO 1515 standard approves 2507 super duplex for use in H₂S-containing environments, making it a trusted material for sour service in oil and gas production.

The table below highlights its resilience against various chemicals.

| Chemical/Environment | Resistance Specifics |

|---|---|

| Chloride Solutions | High resistance, even at elevated temperatures |

| H₂S Environments | Approved for sour service in Oil & Gas (NACE MR0175) |

| Organic Acids | Formic and Acetic acid at high concentrations |

| Alkaline Solutions | High concentrations and temperatures |

| Sulphuric Acid | Concentrations below approximately 25% |

Superior Mechanical Strength

The balanced duplex microstructure gives 2507 super duplex steel a significant mechanical advantage. Its strength is approximately twice that of common austenitic stainless steels like 304 and 316L. This high strength allows for the design of piping systems with thinner walls, reducing both weight and overall material cost without compromising safety or performance.

The mechanical properties of 2507 steel provide the integrity needed to handle high-pressure flows and resist physical deformation.

| Property | Minimum Value |

|---|---|

| Yield Strength | ≥550 MPa (79,800 psi) |

| Tensile Strength | ≥800 MPa (116,000 psi) |

This impressive strength ensures that fittings maintain their structural integrity under extreme mechanical stress, preventing leaks and catastrophic failures in critical applications.

Performance in Extreme Temperatures

2507 super duplex steel maintains its excellent properties across a wide range of temperatures. It is recommended for continuous service at temperatures up to 300°C (572°F), with some standards permitting use up to 316°C (600°F).

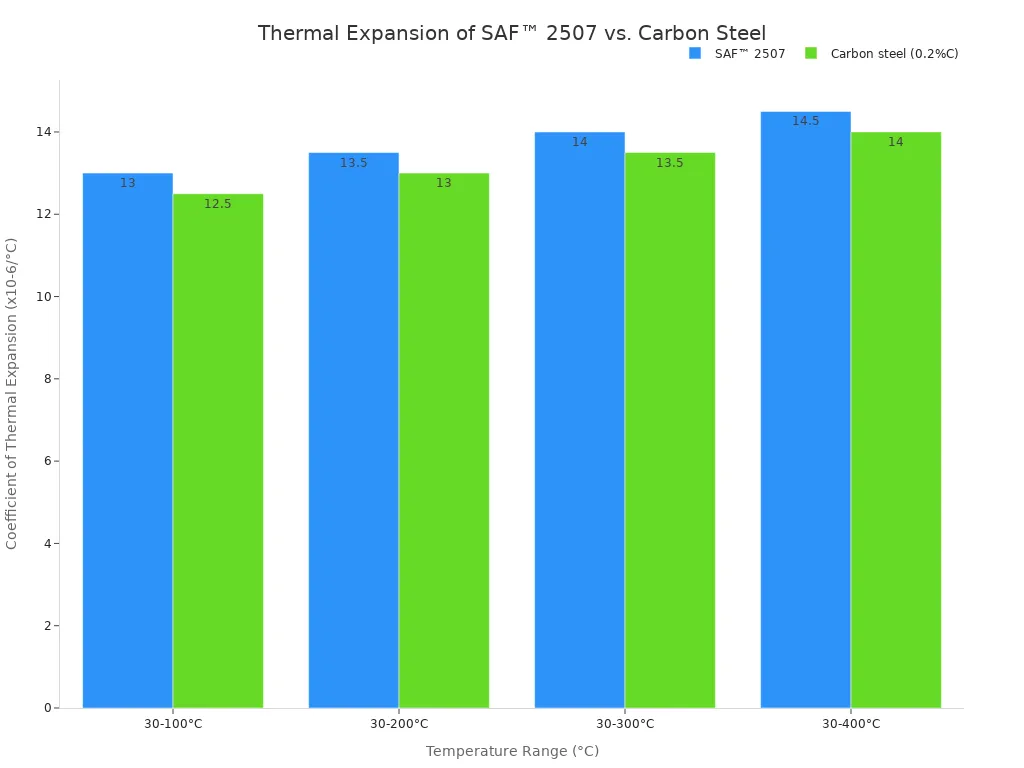

A key design advantage is its low coefficient of thermal expansion, which is very close to that of carbon steel.

This similarity reduces thermal stress in systems that combine both duplex and carbon steel components. It minimizes the risk of distortion or failure during thermal cycling, making it a reliable and predictable material for equipment that experiences frequent temperature fluctuations.

Long-Term Cost-Effectiveness

While the initial purchase price of an ASTM A815 2507 Duplex Steel Elbow may be higher than that of standard stainless steel fittings, a true cost analysis extends over the entire service life of the component. The concept of Total Cost of Ownership (TCO) reveals the superior financial value of 2507 super duplex steel. This forward-thinking approach considers not just the upfront expense but also the long-term operational and maintenance costs.

Industries like oil and gas and chemical processing see significant long-term savings. On offshore platforms, for example, the exceptional corrosion resistance of duplex steel minimizes the need for frequent repairs and replacements in harsh marine environments. This reduction in maintenance activities directly lowers labor costs, material expenses, and, most importantly, costly operational downtime. A system that remains online and productive generates far more value than one that requires constant service interruptions. The reliability of 2507 fittings prevents failures, protecting assets and personnel while ensuring process integrity.

When compared to other high-performance materials, the economic advantages become even clearer. Nickel alloys, for instance, are often considered for extreme environments, but they come at a premium. Super Duplex 2507 offers a more balanced financial solution.

- Nickel alloys are typically two to three times more expensive than Super Duplex 2507.

- Super Duplex 2507 provides similar corrosion resistance to some nickel alloys in many demanding applications.

- The combination of high performance and a more accessible price point makes an ASTM A815 2507 Duplex Steel Elbow a highly cost-effective choice.

- Its lower lifecycle costs are a result of its exceptional durability and resistance to both corrosion and high-pressure conditions.

💡 Strategic Insight: Investing in a material's durability upfront is fundamentally more economical than repeatedly paying for maintenance, repairs, and downtime. The long service life of 2507 super duplex steel makes it a strategic investment in operational stability and financial predictability.

Key Advantages in Harsh Environments

The true value of 2507 super duplex steel becomes evident in its performance under extreme operational stress. Its unique properties provide three critical advantages that ensure reliability where other materials would fail. These benefits directly address the most common and severe challenges found in demanding industrial settings.

Resisting Pitting and Crevice Corrosion

Pitting and crevice corrosion are localized forms of attack that can rapidly perforate standard stainless steels, especially in chloride-rich environments like seawater. The high chromium, molybdenum, and nitrogen content in 2507 super duplex steel provides a powerful defense against these threats. Its high Pitting Resistance Equivalent Number (PREN) is a direct indicator of this capability.

💡 Critical Temperature Performance: Laboratory tests confirm the material's resilience. According to the ASTM G48 standard, 2507 super duplex steel has a Critical Pitting Temperature (CPT) of approximately 78°C in 6% ferric chloride, showcasing its stability at elevated temperatures.

This robust resistance prevents small, localized failures from escalating into major leaks or system-wide integrity issues.

Preventing Stress Corrosion Cracking (SCC)

Stress Corrosion Cracking is a dangerous failure mechanism caused by the combined action of tensile stress and a specific corrosive environment. 2507 super duplex steel’s balanced microstructure makes it highly resistant to SCC. This is particularly important in applications involving hot chloride solutions or sour gas. Tests demonstrate that 2507 steel maintains its ductility in chloride solutions saturated with hydrogen sulphide at temperatures up to 95°C. This indicates excellent resistance to cracking, ensuring long-term safety in oil and gas production and chemical processing.

Withstanding High-Pressure Flows

The superior mechanical strength of 2507 super duplex steel directly translates to an exceptional ability to handle high-pressure conditions. An ASTM A815 2507 Duplex Steel Elbow maintains its structural integrity under intense internal pressures that would deform or rupture weaker materials. This high strength offers several key benefits:

- Ensures reliable containment of high-pressure fluids and gases.

- Allows for system designs with thinner walls, reducing weight and cost.

- Prevents catastrophic failures in critical, high-stress points of a piping system.

This combination of corrosion resistance and strength makes it the definitive choice for ensuring operational safety and efficiency.

Critical Industrial Applications

The superior properties of ASTM A815 2507 Duplex Steel Elbows make them indispensable across several of the world's most challenging industries. Their reliability ensures operational integrity where system failure would have catastrophic consequences.

Oil & Gas: Offshore and Subsea

The oil and gas sector operates in extremely corrosive and high-pressure environments. ASTM A815 2507 Duplex Elbows provide the necessary strength and corrosion resistance for these demanding conditions. They are a primary choice for subsea systems that face constant exposure to seawater and intense pressures. Key applications include:

- Offshore platforms and heat exchangers

- High-pressure RO-plant and seawater piping

- Injection and ballast water systems

- Fire-fighting systems

These fittings ensure long-term reliability in critical infrastructure, from the Aasta Hansteen gas field's subsea manifolds to the mooring systems of floating wind farms.

Chemical Processing Plants

Chemical processing plants handle a wide range of aggressive substances that can quickly degrade standard materials. The robust chemical resistance of 2507 super duplex steel makes it essential for maintaining safety and preventing leaks. These elbows are vital in systems exposed to corrosive agents like organic acids, sulfur compounds, and various chloride solutions. They are frequently specified for use in bleaching equipment, PVC strippers, and chemical manufacturing reactors where material integrity is paramount.

Desalination and Water Treatment

Desalination plants use reverse osmosis to produce fresh water, a process that creates highly concentrated and corrosive brine. ASTM A815 2507 Duplex Elbows excel in this environment. Their high chromium, molybdenum, and nitrogen content provides exceptional resistance to pitting and chloride stress corrosion cracking. This durability translates directly into significant operational and financial benefits.

💡 Proven Performance: In desalination applications, 2507 duplex steel offers a 65% longer equipment lifespan compared to standard duplex grades. One Middle East plant even reduced its annual maintenance costs by 35% after upgrading to 2507 components.

This makes 2507 the premier material for high-pressure pumps and brine concentrators, ensuring long-term performance and cost-effectiveness.

Pulp and Paper Manufacturing

The pulp and paper industry presents significant material challenges due to its use of aggressive bleaching chemicals and high-temperature processes. ASTM A815 2507 Duplex Elbows provide a robust solution, offering exceptional durability in these corrosive environments. The material's high mechanical strength and superior corrosion resistance make it ideal for critical equipment.

2507 super duplex steel excels in specific process conditions where other materials falter:

- Acidic Chlorine Environments: It delivers corrosion resistance comparable to high-alloyed austenitic grades while providing much higher mechanical strength.

- Hot Water and Chlorides: The duplex microstructure makes it extremely resistant to stress corrosion cracking in warm, chloride-heavy water (above 50°C), a common point of failure for standard austenitic steels.

This resilience ensures longer service life for key components, reducing maintenance needs and preventing costly production halts.

Marine and Shipbuilding

Marine environments are relentlessly corrosive, with constant saltwater exposure demanding the highest level of material performance. ASTM A815 2507 Duplex Elbows are a premier choice for shipbuilding and offshore applications, ensuring the longevity and safety of critical systems. Their outstanding resistance to pitting, crevice corrosion, and chloride-induced cracking makes them indispensable for seawater handling.

💡 Did You Know? The high strength of 2507 super duplex steel allows for the construction of lighter components without sacrificing durability, a key advantage in shipbuilding where weight reduction is crucial.

This material is specified for a wide range of demanding marine applications, including:

- Ship hulls and structural elements for offshore platforms

- Propellers, shafts, and fasteners

- Pump components and other marine equipment

- Seawater piping for desalination plants

Using these high-performance elbows protects vital marine assets from premature failure, ensuring operational reliability on the high seas.

Technical and Fabrication Guide

Understanding the technical specifications of 2507 super duplex steel is essential for ensuring its successful application and fabrication. Proper handling preserves the material's unique properties and guarantees long-term performance in demanding environments.

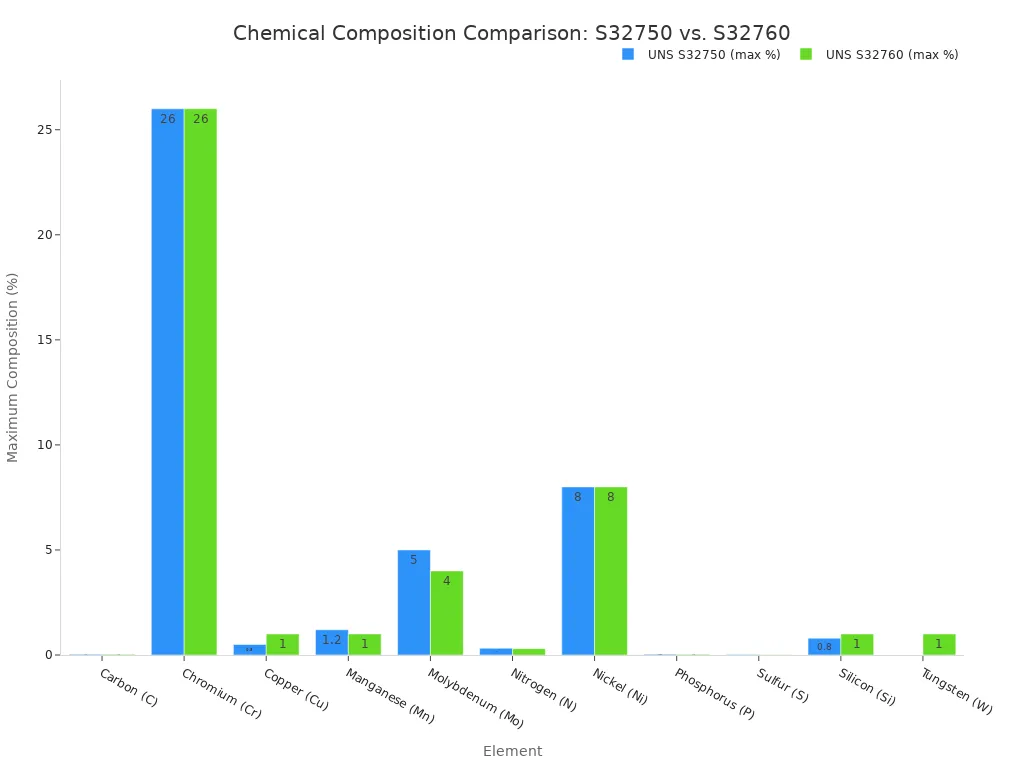

Chemical Composition of UNS S32750

The exceptional performance of UNS S32750 originates from its precisely controlled chemical composition. The high levels of chromium, molybdenum, and nitrogen are fundamental to its superior corrosion resistance and strength.

| Element | Range (%) |

|---|---|

| Chromium (Cr) | 24.0 – 26.0 |

| Molybdenum (Mo) | 3.0 – 5.0 |

| Nitrogen (N) | 0.24 – 0.32 |

While often grouped with other super duplex grades, UNS S32750 has a distinct chemical balance. For example, compared to its counterpart UNS S32760, it contains no added tungsten and has a lower maximum copper content. These subtle differences optimize its performance for specific corrosive conditions.

Mechanical Property Benchmarks

ASTM A815 sets clear benchmarks for the mechanical properties of 2507 duplex elbows to ensure they can withstand high-pressure and high-stress service. These fittings deliver impressive strength and ductility.

| Property | Minimum Value |

|---|---|

| Yield Strength | 550 MPa (80,000 psi) |

| Tensile Strength | 800 MPa (116,000 psi) |

| Elongation | 15% |

💡 Quality Assurance: To verify these properties, standards mandate hardness testing. Manufacturers perform Brinell or Rockwell hardness tests on material samples from each production lot to confirm compliance and material integrity.

Best Practices for Welding and Forming

Fabricating 2507 super duplex steel requires careful procedures to maintain its balanced microstructure and performance characteristics.

- Welding: Proper welding is critical. Fabricators should use a recommended filler metal, such as 2507/P100, to ensure the weld maintains the correct duplex structure.

- Heat Control: Careful control of heat input is necessary to prevent the formation of undesirable phases that could reduce toughness and corrosion resistance.

- Post-Weld Heat Treatment (PWHT): PWHT is generally recommended after welding. This process helps restore the material's mechanical properties and corrosion resistance in the heat-affected zone, ensuring the entire component performs as designed.

Following these guidelines is key to unlocking the full potential of an ASTM A815 2507 Duplex Steel Elbow.

The combination of high strength, superior corrosion resistance, and durability makes the ASTM A815 2507 Duplex Steel Elbow the definitive choice for critical systems. These fittings ensure operational safety, minimize downtime, and provide long-term reliability in the world's most challenging industrial environments. The future for duplex steel is promising, driven by ongoing product innovations and growing demand in emerging markets.

💡 Strategic Move: Investing in these high-performance fittings is a forward-thinking decision to protect assets and ensure process integrity for years to come.

FAQ

What makes 2507 a "super duplex" steel?

Super duplex 2507 contains higher levels of chromium, molybdenum, and nitrogen than standard duplex grades. This enhanced composition gives it superior strength and exceptional corrosion resistance. Its Pitting Resistance Equivalent Number (PREN) is above 40, classifying it for the most severe service environments.

Can you weld 2507 duplex steel?

Yes, fabricators can weld 2507 duplex steel. The process requires specific procedures to maintain its properties. Welders must use appropriate filler metals and control heat input carefully. Post-weld heat treatment is often recommended to ensure optimal performance of the welded area.

Is 2507 duplex steel magnetic? 🧲

Yes, 2507 duplex steel is magnetic. Its two-phase microstructure contains a significant amount of ferrite, which is a magnetic phase. This property distinguishes it from common austenitic stainless steels like 304 or 316, which are generally non-magnetic.

Why is the ASTM A815 standard important for these elbows?

The ASTM A815 standard acts as a quality guarantee. It mandates strict requirements for manufacturing, chemical balance, and mechanical strength. Adherence to this standard ensures every 2507 elbow provides the reliability and safety necessary for high-pressure, critical industrial systems.

See Also

Mastering Pass Partition Plate Welding: Expert Techniques for 2025 Success

Industrial Semi-Welded Plate Heat Exchangers: A Comprehensive Guide for 2025

Optimizing Heat Exchange: Steel Processing Techniques for Consistent Performance

ASME BPVC Section VIII: Material Selection for Pressure Vessel Integrity

Revolutionary Materials: Transforming the Future of Heat Exchanger Supply Chains