Optimizing the Food Supply Chain with AI for Less Waste

Globally, around one-third of all food produced is lost or wasted. The artificial intelligence food industry confronts this challenge directly. It uses data to make highly accurate predictions and automate key decisions. AI-driven tools enhance demand forecasting and streamline inventory management, ensuring food reaches consumers before spoiling.

How the Artificial Intelligence Food Industry Prevents Waste at the Source

Waste reduction begins long before food reaches a store shelf. The artificial intelligence food industry provides powerful tools to optimize operations at the earliest stages of the supply chain: on the farm, in the processing facility, and during distribution. By embedding intelligence into these foundational steps, producers can prevent losses, improve quality, and create a more efficient system from the ground up.

Precision in Agriculture and Production

Precision agriculture uses technology to make farming more accurate and controlled. AI is the engine driving this transformation, turning raw data into actionable strategies that boost yields and minimize pre-harvest losses. Drones and on-ground sensors equipped with AI algorithms constantly monitor crop health with incredible detail.

These systems provide farmers with critical alerts and insights:

- Early Disease and Pest Detection: AI analyzes multispectral images from drones to find subtle signs of plant stress or insect damage invisible to the human eye. This allows for targeted treatment instead of broad, wasteful pesticide application.

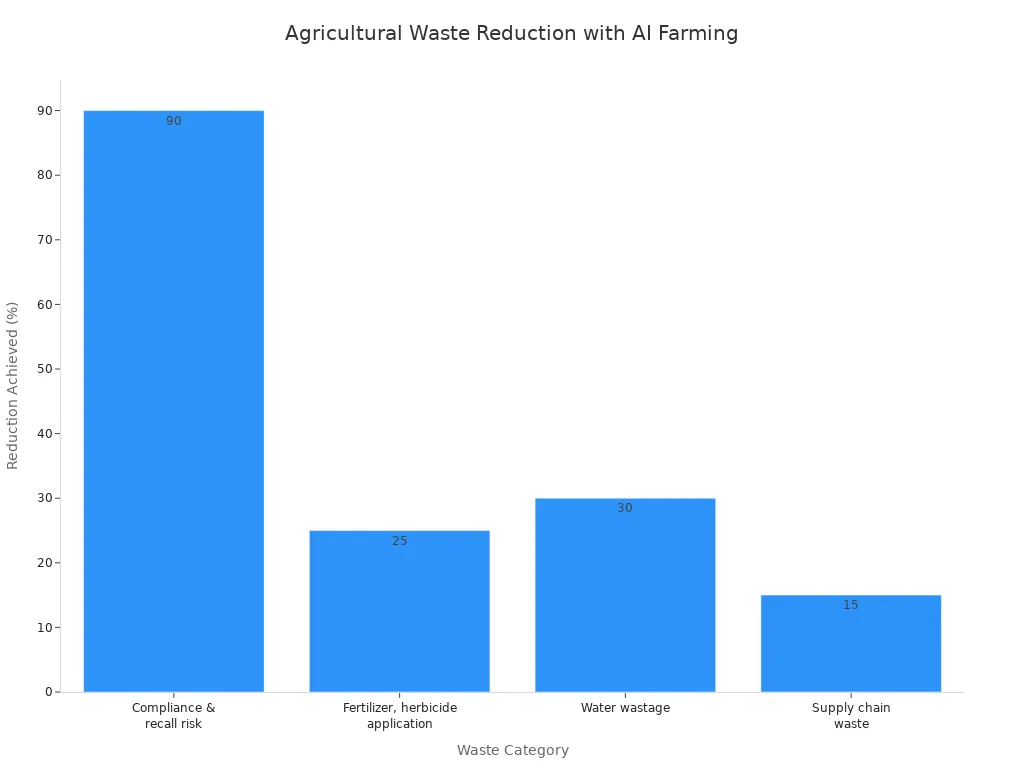

- Optimized Resource Use: AI-integrated smart sensors monitor soil moisture and nutrient levels in real-time. This data feeds into automated irrigation and fertigation systems, which apply water and fertilizer precisely where needed. This practice can cut water wastage by up to 30% and reduce fertilizer use by around 25%.

- Accurate Yield Prediction: Deep learning models like Random Forest Regressors and Convolutional Neural Networks (CNNs) analyze historical data, weather patterns, and sensor readings. They predict harvest yields with high accuracy, allowing farmers to plan for labor, storage, and transportation more effectively.

This data-driven approach significantly reduces waste at the source. By optimizing inputs and intervening early, farmers prevent crop loss and improve overall resource efficiency.

Smarter Processing and Quality Control

Once produce leaves the farm, it enters the processing stage, another critical point for potential waste. Manual inspection is slow, subjective, and prone to error. AI-powered computer vision systems revolutionize this process. Using high-resolution cameras and advanced sensors, these systems inspect products on the line with superhuman speed and accuracy.

AI excels at identifying issues that human inspectors often miss. These systems can achieve defect detection rates exceeding 99%. In contrast, manual inspections can miss up to 40% of flaws due to fatigue or inconsistency. AI analyzes products for imperfections in size, shape, color, and even texture. More importantly, it learns from the data it collects.

Instead of simply discarding an imperfect item, AI-powered sorting machines can categorize produce into different quality grades. A slightly misshapen tomato might not be suitable for premium grocery display, but it is perfect for canning or sauce production. This intelligent grading finds a market for more of the harvest, directly reducing food waste.

Furthermore, AI tools can predict the shelf life of perishable goods. Systems like DeltaTrak's Freshness Index use IoT sensor data and predictive models to calculate remaining freshness in real-time. This allows processors to prioritize items with shorter shelf lives for quicker distribution, ensuring products reach consumers at peak quality.

Optimized Logistics and Distribution

Transporting perishable food is a race against time. The artificial intelligence food industry optimizes this critical journey to minimize spoilage and improve efficiency. AI algorithms create the most effective transportation routes, saving both time and fuel.

These logistics platforms use several techniques:

- Clustering Algorithms: Group deliveries by geographic location to reduce total mileage.

- Shortest Path Algorithms: Analyze live traffic and road conditions to find the fastest route between points.

- Constraint Solvers: Factor in delivery windows, vehicle capacity, and driver schedules to create compliant and efficient plans.

Beyond routing, AI-enabled IoT sensors inside "smart containers" monitor the condition of goods during transit. These sensors track temperature and humidity, alerting logistics managers to any deviations from the optimal range. This real-time monitoring allows for immediate intervention, preventing entire shipments from spoiling. Companies like Unilever and Fresho have already used AI to improve forecast accuracy and reduce spoilage by 30-40%. This optimized approach not only cuts food waste by up to 30% but also reduces the associated carbon footprint, making the entire supply chain more sustainable.

How AI Aligns Supply with Demand in Retail and Consumption

The final stages of the food supply chain—retail and consumption—are where the consequences of inefficiency become most visible. Empty shelves and overflowing dumpsters represent a fundamental disconnect between what is supplied and what is needed. The artificial intelligence food industry addresses this gap by creating a responsive, data-driven ecosystem that extends from the grocery store aisle all the way to the consumer's kitchen. This alignment minimizes waste, improves profitability, and fosters more sustainable consumption patterns.

Hyper-Accurate Retail Demand Forecasting

Traditional forecasting methods often rely on historical sales data alone, leaving retailers vulnerable to sudden shifts in consumer behavior. AI-powered demand forecasting revolutionizes this process by analyzing millions of data points in real time. These systems identify complex patterns that human analysis would miss, leading to far more precise predictions. Organizations that automate their data preparation can improve forecast precision by up to 20% and achieve overall accuracy rates exceeding 80%.

AI models integrate a wide array of external variables to refine their forecasts. This multi-dimensional analysis provides a holistic view of market dynamics. Key factors include:

- Weather and Seasonality: Algorithms automatically model multiple seasonal patterns (weekly, monthly, annual) and correlate them with weather forecasts to predict demand for items like soup in winter or ice cream in summer.

- Holidays and Local Events: The system learns the specific impact of holidays, festivals, and local sporting events on purchasing habits, allowing stores to stock up appropriately.

- Economic Indicators and Social Trends: AI can incorporate economic data and even analyze social media trends to detect emerging consumer preferences before they become mainstream.

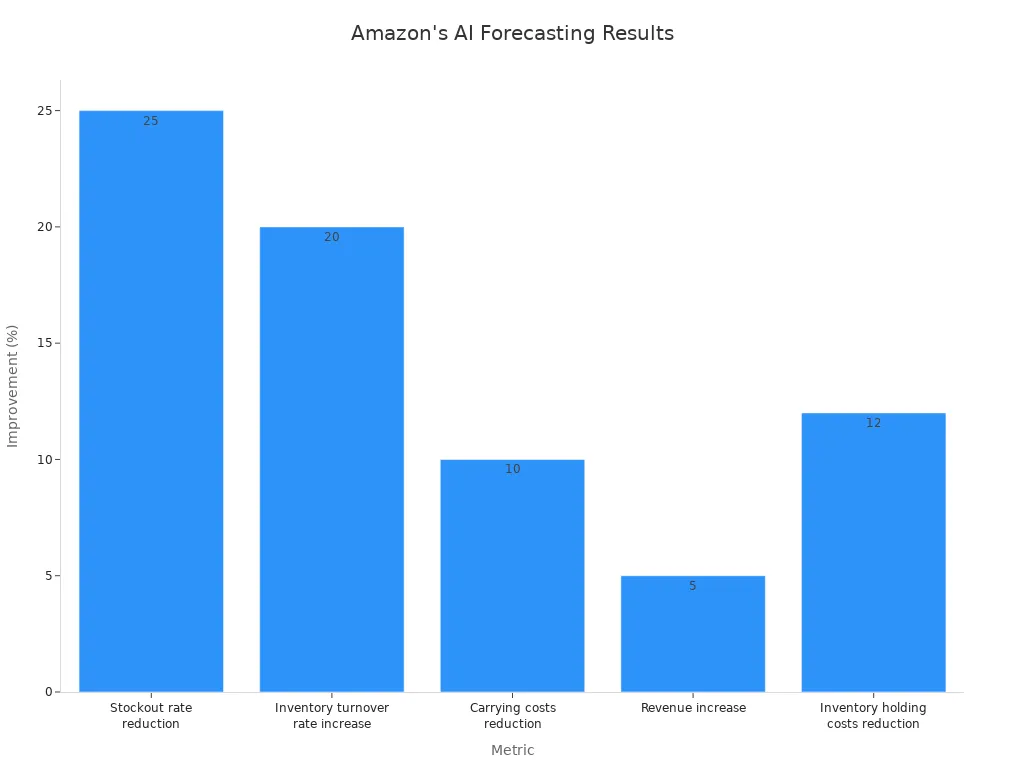

Major retailers are already demonstrating the power of this technology. Target’s AI platform uses datasets on everything from online search behavior to regional purchasing trends to autonomously adjust forecasts for each product. Amazon employs deep learning algorithms to predict inventory needs down to the specific SKU, size, and store location. This has enabled the company to significantly reduce stockouts and carrying costs.

| Metric | Amazon's AI Forecasting Results |

|---|---|

| Stockout rate reduction | 25% |

| Inventory turnover rate increase | 20% |

| Carrying costs reduction | 10% |

| Revenue increase | 5% |

| Inventory holding costs reduction | 12% |

Dynamic Pricing and Inventory Management

Accurate forecasting is the foundation for smarter inventory and pricing strategies. AI enables retailers to move from static, reactive models to dynamic, proactive systems that maximize sales and minimize spoilage. One of the most effective tools is AI-driven dynamic pricing for perishable goods.

By training models to analyze sales patterns, expiration dates, and demand fluctuations, retailers can adjust prices dynamically, ensuring that perishable goods sell before becoming unsellable.

This process is highly automated and data-intensive. AI systems execute several key steps to optimize pricing for items nearing their expiration date:

- Data Integration: The system gathers real-time data from POS systems, IoT sensors tracking shelf life, and competitor pricing.

- Machine Learning Analysis: Algorithms process hundreds of data points to predict demand elasticity and recommend the optimal discount rate needed to clear stock without eroding profits.

- Automated Price Adjustments: Pricing tools automatically apply markdowns to digital price tags, eliminating the need for manual intervention and ensuring timely adjustments.

- Customer Segmentation: AI can even tailor offers to specific customer segments based on their price sensitivity and purchase history, further increasing the likelihood of a sale.

Beyond pricing, AI platforms like RELEX Solutions offer end-to-end inventory management. These systems automate replenishment, manage fresh inventory, and optimize stock levels for promotions. AI analyzes data from past sales events to predict how a new promotion will increase demand. This allows businesses to order the correct amount of stock, preventing the overstocking that often leads to waste after a sale ends.

Influencing Smarter Consumer Habits

Food waste reduction ultimately extends into the home, where a significant portion of waste occurs. AI is now empowering consumers with tools to manage their food more effectively and make more conscious purchasing decisions.

Smart kitchen technology is at the forefront of this shift. Research from institutions like Wageningen University & Research shows that smart refrigerators equipped with AI can significantly reduce over-purchasing. These appliances use internal cameras and sensors to track inventory, monitor freshness, and send alerts for items nearing their expiration date. This moves consumers beyond static "best by" dates toward a dynamic understanding of food's actual shelf life.

Mobile apps also play a crucial role in bringing this intelligence to everyone.

- Inventory Tracking: Apps like FoodWise and My Pantry Tracker use AI to simplify home inventory. Users can scan barcodes or snap a photo of groceries, and the app’s AI will identify the items, categorize them, and set reminders for expiration dates.

- Recipe Generation: To help use what is on hand, AI-powered recipe generators like DishGen and CookAIFood suggest meals based on a list of available ingredients. This turns leftover items into new meal ideas, directly preventing them from being thrown away.

- Personalized Shopping: AI-driven shopping lists learn a household's unique buying habits, including brand preferences and dietary needs. The system creates tailored lists that help consumers buy only what they need, reducing impulse purchases and preventing the accumulation of unused food.

By providing personalized insights and actionable recommendations, AI gives consumers the practical tools needed to participate actively in waste reduction.

The artificial intelligence food industry provides the actionable intelligence needed to build a more efficient, less wasteful system. It offers practical tools that optimize processes from harvesting to consumer purchasing, significantly reducing global food waste. The future of a sustainable food system relies on this technology to connect supply with demand precisely.

FAQ

Is AI technology too expensive for small farms or retailers?

AI solutions are becoming more accessible. Many providers offer scalable, subscription-based models. This approach lowers initial costs and makes the technology affordable for smaller businesses.

What are the primary benefits of using AI in the food supply chain?

AI primarily reduces waste through accurate demand forecasting. It also optimizes logistics, improves quality control, and enables dynamic pricing to sell perishable goods before they spoil.

How does AI help consumers reduce food waste at home?

Smart kitchen apps and appliances use AI to track inventory. They suggest recipes for leftover ingredients and send alerts for items nearing their expiration date.

See Also

Enhancing 2 5-Furandicarboxylic Acid Sustainability Through Data-Driven Strategies

Essential Industrial Checkweighers: Three Must-Have Devices For Food Plants

Key Capsule Checkweighers For Buyers To Evaluate In The Year 2025

Modern Capsule Decapsulation Machines: Boosting Pharmaceutical Efficiency And Productivity

Forecasting Top Folder Gluer Features For 2025 Carton Production Lines