Understanding the Applications of 1.4542 Stainless Steel

The material 1.4542 is a high-strength, corrosion-resistant stainless steel. Demanding industries like aerospace, petrochemical, and medical rely on it for critical components. Engineers specify it for aircraft parts, valve components, and pump shafts. The unique combination of strength and toughness comes from a special heat treatment process. This makes a 17-4PH 630 Stainless Steel Bar ideal for these challenging roles.

The global market for 17-4PH stainless steel, also known as 1.4542, shows significant projected growth, highlighting its increasing importance in modern manufacturing.

Key Takeaways

- 1.4542 stainless steel is very strong and resists rust. It is used in tough jobs like making airplane parts and medical tools.

- This steel works well in many industries. It helps make parts for planes, oil rigs, and medical devices that need to be very reliable.

- Heat treatment changes how strong and tough this steel is. Engineers can choose different heat treatments to make the steel fit specific needs.

- The H1150 heat treatment makes the steel very tough. It helps the steel resist cracking in harsh places, like oil fields with bad gases.

- Sometimes, other steels are better. If you need super strong rust protection or extreme hardness, other materials might be a better choice.

Core Applications by Industry

The unique properties of 17-4PH stainless steel make it a go-to material for components that must perform flawlessly under extreme stress. Its versatility allows engineers across different sectors to solve complex design challenges. The material's adoption in critical fields demonstrates its reliability and superior performance.

Aerospace and Defense

In the aerospace and defense industries, every component's weight and strength are critical for safety and performance. This material provides an exceptional strength-to-weight ratio, making it essential for flight-critical applications. Manufacturers use it to produce parts that withstand immense mechanical loads and vibrations during flight.

Key aerospace components fabricated from this steel include:

- Aircraft fuselage structural components

- Engine mounts and shafts

- Landing gear parts

- Gears and actuators

- High-strength fasteners

These parts demand high fatigue strength and toughness to ensure long-term operational integrity. The material's reliability directly contributes to safer and more efficient aircraft.

Oil, Gas, and Petrochemical

The oil, gas, and petrochemical sectors operate in some of the world's most corrosive and high-pressure environments. Equipment must resist chemical attack while handling intense mechanical stress. The excellent corrosion resistance and high strength of 1.4542 make it a premier choice for these demanding conditions. It is frequently specified for components in direct contact with abrasive and corrosive fluids.

Common applications in this industry are:

- Valve bodies, seats, and fittings

- Pump shafts and impellers

- Downhole tools and equipment

- Flanges and high-pressure nozzles

Pro Tip: For service in marine or sour gas environments, a double-aging heat treatment like H1150M significantly enhances the material's resistance to stress corrosion cracking, extending component life and improving safety.

Medical and Dental

The medical field requires materials that are not only strong and durable but also biocompatible and easily sterilized. This stainless steel meets these stringent requirements, making it suitable for a wide range of medical and dental devices. Its hardness allows it to maintain a sharp edge, while its corrosion resistance ensures it can withstand repeated sterilization cycles without degrading.

Medical professionals rely on instruments and devices made from this material, such as:

- Surgical cutting tools, rasps, and forceps

- Specialized medical screwdrivers

- Orthopedic implants and fixtures

- Dental instruments, including burs and brackets

The combination of strength, wear resistance, and cleanability ensures that these tools perform reliably in critical surgical and dental procedures.

High-Performance Manufacturing

Modern manufacturing demands materials that deliver both strength and precision. The unique properties of 1.4542 make it a valuable asset for creating durable tooling and machinery components. Its high hardness and excellent wear resistance allow it to withstand the rigors of high-volume production cycles, especially in abrasive environments. This ensures longer tool life and consistent part quality.

Engineers in advanced manufacturing sectors specify this steel for several critical roles:

- Injection Molds: It is used for molds and screws, particularly for processing abrasive, glass-fiber-reinforced plastics. Its hardness prevents rapid wear.

- High-Speed Shafts: The material's high strength and fatigue resistance make it ideal for shafts that operate under significant torque and rotational stress.

- Metal Injection Molding (MIM): The material itself can be formed using MIM processes to create complex, high-strength parts efficiently.

The precipitation-hardened microstructure of this steel provides exceptional dimensional stability. This allows tooling to maintain tight tolerances even after millions of cycles, ensuring consistent and precise manufacturing output.

The material's reliable performance stems from its ability to be heat-treated to specific hardness levels. This customization allows manufacturers to balance strength with toughness for different applications. Its consistent mechanical properties provide a predictable and dependable solution for building robust manufacturing equipment.

Why Choose 1.4542? Key Properties Explained

Engineers select materials based on a careful balance of mechanical properties. The material 1.4542, or 17-4PH, offers a superior combination of strength, corrosion resistance, and toughness. This blend makes it a standout choice for components that cannot fail. Understanding these core attributes reveals why it is so valuable in critical industries.

High Strength and Hardness

The defining characteristic of this steel is its exceptional strength and hardness. It achieves these properties through a precipitation hardening heat treatment process. In its solution-annealed state, the material is relatively soft and easy to machine. A subsequent aging treatment at a specific temperature causes microscopic copper-rich precipitates to form within the steel's matrix. These precipitates obstruct internal movement, dramatically increasing the material's strength and hardness.

The H900 condition, achieved by aging at 900°F (482°C), maximizes these properties. This treatment produces a material capable of withstanding extreme mechanical stress and wear.

| Property | Typical Value (H900 Condition) |

|---|---|

| Ultimate Tensile Strength | ~1310 MPa (190 ksi) |

| Hardness (Rockwell C) | ~44 HRC |

This high level of strength ensures that components maintain their structural integrity under heavy loads, making it ideal for applications like landing gear and high-pressure pump shafts.

Good Corrosion Resistance

This stainless steel provides good corrosion resistance in a wide range of atmospheric and mildly corrosive chemical environments. Its performance is comparable to grade 304 stainless steel in many situations. The 17% chromium content is the primary element responsible for creating a passive, corrosion-resistant surface layer. This makes it suitable for equipment in food processing, petrochemical plants, and general industrial settings where moisture and mild chemicals are present.

Note: Engineers must carefully evaluate the service environment. In environments with high concentrations of chlorides, such as marine settings or certain chemical processing streams, the material can be susceptible to pitting and stress corrosion cracking. Selecting an appropriate heat treatment can help mitigate these risks for specific applications.

Excellent Toughness and Fatigue Life

Strength alone is not enough for demanding applications. A material must also possess toughness—the ability to absorb energy and resist fracture. This steel delivers excellent toughness, especially in heat treatment conditions that balance strength with ductility. This property is critical for components that experience sudden impacts or shock loads.

Heat treatment allows for the customization of toughness levels. For example, aging the material at higher temperatures enhances its impact resistance:

- H1075 Condition: Provides a Charpy V-notch impact value of approximately 54 Joules.

- H1150 Condition: Offers an even higher impact value of around 68 Joules.

This excellent toughness, combined with high strength, results in a superior fatigue life. Components can endure millions of stress cycles without failing, a vital attribute for rotating parts, actuators, and structural aerospace components that are subject to constant vibration and loading.

Superior Wear Resistance

Wear resistance is a critical performance metric for components subjected to friction, abrasion, and sliding contact. The inherent high hardness of 1.4542 stainless steel provides exceptional resistance to wear and galling. This property ensures components maintain their shape and function over long service periods, reducing maintenance and replacement costs. The material's dense, hardened microstructure effectively withstands surface degradation from mechanical action.

This makes it an ideal choice for parts in constant motion or contact:

- Bearings and bushings

- Valve seats and stems

- Gears and splines

- Tooling for abrasive materials

For applications facing extreme abrasive or erosive conditions, engineers can specify advanced surface treatments to further boost performance. Processes like plasma nitriding and nitrocarburizing diffuse nitrogen into the steel's surface, creating an exceptionally hard outer case.

These surface modification techniques can increase the surface hardness to over 1200 HV, with some treatments achieving up to 2000 HV. This improvement comes from the formation of hard metallurgical phases like iron nitrides (Fe4N) and chromium nitrides (CrN). The result is a dramatic reduction in the wear rate, often by orders of magnitude.

This ultra-hard surface layer protects the tough, strong core of the component. It allows parts made from this steel to function reliably in environments with abrasive media, such as plastic injection molds processing glass-filled polymers or pump components handling slurries. The combination of a tough substrate and a wear-resistant case makes the material uniquely suited for the most demanding industrial challenges.

How Heat Treatment Customizes 1.4542 for Applications

The true versatility of 1.4542 stainless steel comes from heat treatment. Engineers can precisely tailor its mechanical properties through a process called precipitation hardening, or aging. This allows them to optimize the material for a specific application, balancing strength, toughness, and corrosion resistance. The process starts with the material in its solution-annealed state and ends with a finished component ready for extreme service.

Condition A: The Solution-Annealed State

Suppliers typically deliver 1.4542 steel in Condition A. This is the solution-annealed state, where the material is at its softest and most ductile. This condition makes the steel easier to machine, form, and weld before the final hardening process. While not intended for final service, it possesses respectable mechanical properties.

| Property | Typical Value |

|---|---|

| Tensile Strength | ~1100 MPa |

| Hardness (Rockwell C) | ~36 HRC |

This machinable state allows manufacturers to create complex geometries with greater ease before applying a hardening treatment.

H900: Maximum Strength and Hardness

For applications demanding the highest possible strength and wear resistance, engineers specify the H900 condition. To achieve this, they age the solution-annealed material at 482°C (900°F) for one hour. This treatment precipitates fine copper particles within the steel's matrix, significantly increasing its hardness and strength.

This condition is ideal for:

- High-pressure valve components

- Gears and shafts

- Aircraft structural parts

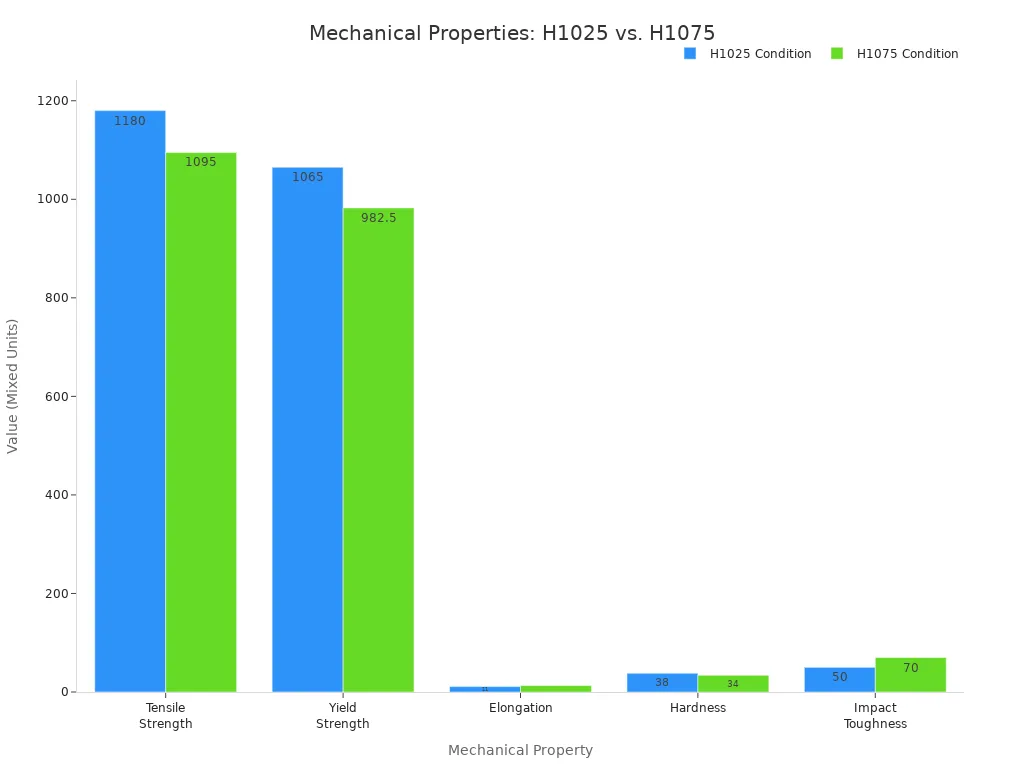

H1025 & H1075: Balanced Strength and Toughness

Many applications require a balance between strength and toughness. The H1025 and H1075 conditions provide this compromise. Aging at higher temperatures reduces the ultimate strength slightly but significantly improves ductility and impact resistance.

- H1025: Offers a great balance with high strength and good toughness.

- H1075: Sacrifices more strength to gain superior toughness and ductility.

The table and chart below illustrate the trade-offs between these two popular conditions.

| Property | H1025 Condition | H1075 Condition |

|---|---|---|

| Tensile Strength | 1160–1200 MPa | 1070–1120 MPa |

| Hardness | 36–40 HRC | 32–36 HRC |

| Impact Toughness | 40–60 J | 60–80 J |

Choosing between these conditions allows engineers to fine-tune the material for parts like landing gear or downhole oil tools, where both strength and fracture resistance are critical.

H1150: Maximum Toughness and Stress Corrosion Resistance

When an application prioritizes maximum toughness and resistance to stress corrosion cracking (SCC) over sheer strength, engineers specify the H1150 condition. This heat treatment involves aging the material at a high temperature of 621°C (1150°F). The process significantly improves the steel's ductility and ability to absorb impact energy. This enhancement in toughness makes it the premier choice for components in harsh environments where brittle fracture is a primary concern.

The trade-off for this increased toughness is a reduction in hardness and tensile strength compared to lower-temperature aging treatments. The following table clearly illustrates the differences between the H1150 and H1025 conditions.

| Property | H1150 Condition | H1025 Condition | Difference |

|---|---|---|---|

| Toughness | Higher | Moderate | Better impact resistance |

| Elongation | 10-16% | 8-12% | 4-6% higher |

| Hardness | 32-38 HRC | 38-44 HRC | 6-10 points lower |

| Applications | General structural | High strength critical | Different use cases |

This profile makes H1150 ideal for critical service in the oil and gas industry, particularly in "sour service" applications containing hydrogen sulfide (H₂S).

🛡️ NACE MR0175/ISO 15156 Compliance: This international standard governs materials for use in H₂S-containing environments. To prevent catastrophic sulfide stress cracking, it limits the maximum hardness of 1.4542 steel to 33 HRC. The H1150 condition is essential for meeting this safety-critical requirement.

A notable example involves offshore platforms in challenging environments like Brazil's pre-salt fields. Petrobras required 1.4542 H1150 bars for applications exposed to chlorides, moderate hydrogen sulfide, and dynamic loads. The material's documented toughness and compliance with NACE standards were crucial. After years of service in one of the world's most demanding offshore settings, the components showed no failures, proving the reliability of the H1150 condition.

When to Consider Alternatives

While 1.4542 offers an exceptional blend of properties, it is not the universal solution for every engineering challenge. Specific application requirements may call for a different material. Understanding when to choose an alternative ensures optimal performance and cost-effectiveness.

For General Corrosion Resistance

Many applications prioritize corrosion resistance over the ultra-high strength of 1.4542. In these cases, other stainless steel grades provide a more economical choice. For example, 304 stainless steel is a cost-effective material suitable for kitchenware, tanks, and architectural components in mild environments. For applications with greater chloride exposure, such as marine or pharmaceutical settings, 316L stainless steel offers enhanced corrosion resistance due to its molybdenum content. Choosing these austenitic grades is practical when the extreme mechanical strength of 1.4542 is not a critical design requirement.

For Extreme Corrosion Environments

The material 1.4542 performs well in many corrosive settings, but it has limits. Extremely aggressive chemical processing or high-temperature marine environments can overwhelm its protective capabilities.

Expert Insight: In scenarios involving highly concentrated acids, chlorides, or sour gas at elevated temperatures, engineers should consider nickel-based superalloys. Materials like Inconel® or Hastelloy® offer superior resistance to pitting, stress corrosion cracking, and high-temperature oxidation.

These advanced alloys provide the necessary reliability for the most severe industrial services where material failure is not an option.

For Maximum Hardness and Wear

Some manufacturing and tooling applications demand hardness and wear resistance beyond what 1.4542 can provide. While its hardness is excellent, specialized materials exist for extreme abrasion and cutting tasks.

Consider these alternatives for maximum wear performance:

- Tool Steels (e.g., D2, M2): These high-carbon alloys are designed for cutting tools, dies, and punches. They offer superior edge retention and abrasion resistance.

- Carbide Materials: Tungsten carbide and other cemented carbides provide exceptional hardness for cutting, grinding, and high-wear components.

- Surface-Coated Components: Applying a ceramic coating like Titanium Nitride (TiN) to a tough substrate can create a part with extreme surface hardness for specialized wear applications.

The material 1.4542 is a premier choice for applications needing a superior blend of high strength, good corrosion resistance, and toughness. It serves as a critical material in demanding sectors like aerospace, petrochemical, and medical.

To make the right choice, engineers must evaluate an application's primary need—whether it is strength, corrosion resistance, or a balance of both—to confirm if this steel is the optimal solution.

FAQ

What are the common names for 1.4542?

Engineers commonly refer to 1.4542 by several names. The most frequent designations include 17-4PH, UNS S17400, and grade 630. These terms all describe the same high-performance precipitation-hardening steel and are used interchangeably across industries.

Is 1.4542 stainless steel magnetic?

Yes, 1.4542 is ferromagnetic. Its martensitic crystal structure makes it magnetic in all heat treatment conditions. This property is important for material handling and sorting processes in manufacturing environments.

How does its cost compare to other stainless steels?

The material 1.4542 is generally more expensive than common austenitic grades like 304 or 316. Its higher cost reflects the inclusion of alloying elements like copper and niobium. The price justifies its superior strength and performance in demanding applications.

Can you weld 1.4542 steel?

Yes, fabricators can weld 1.4542 using common methods. Welding is best performed on the material in its solution-annealed (Condition A) state. A post-weld heat treatment is then necessary to restore the component's high-strength properties and ensure joint integrity.

See Also

Optimized Steel Processing: Consistent Performance in Heat Exchange Systems

Welding Pass Partition Plates: Expert Techniques for 2025 Success

WT20 Thoriated Tungsten: Enhancing TIG Welding Performance with Key Facts

Molybdenum Plugs: Assessing Their Role in Seamless Steel Pipe Production 2025

Molybdenum High-Temperature Furnaces: Understanding Their Design and Functionality