The Business Case for Macadamia Sorters

A modern macadamia nuts sorting machine delivers a strong Return on Investment (ROI) for commercial processors. This financial gain stems from several key areas.

Processors experience lower labor costs, recover more high-grade kernels, and produce superior products. These quality improvements enable them to secure premium market prices.

Quantifying the 'Return': Key Profit Drivers

A macadamia nuts sorting machine directly impacts profitability by improving output and quality. Processors can measure this return through increased yield, premium pricing opportunities, and stronger brand protection. These factors transform the sorter from a simple piece of equipment into a strategic profit-generating asset.

Increase Yield and Kernel Recovery

Automated sorters significantly boost the recovery of valuable kernels. For example, the processor Golden Macadamias successfully halved its level of unsound nuts from 8% to 4% using advanced sorting technology. This improvement directly increases the volume of saleable product. Sorters achieve this by operating with consistent precision for extended periods. They detect subtle defects that are often invisible to the human eye, minimizing the rejection of good kernels and maximizing overall yield.

Enhance Product Quality for Premium Pricing

Superior product quality allows processors to command premium prices in a competitive market. An optical sorter meticulously removes defective nuts, ensuring the final batch meets the highest standards. This technology identifies a wide range of imperfections.

Key defects removed by automated sorters include:

- Insect infestation and wormy nuts

- Shrinkage and discoloration

- Mold and dry rot

- Oiled or over-dried kernels

By delivering a consistently flawless product, processors can build a reputation for excellence and justify higher price points.

Improve Food Safety and Brand Reputation

Protecting consumers and brand reputation is a critical function of modern sorting. Macadamia nuts have faced recalls due to bacterial contamination like Salmonella. A macadamia nuts sorting machine helps remove foreign materials that can carry such pathogens. Furthermore, tree nut allergies represent a severe health risk. While sorters do not remove allergens, their role in maintaining a clean, contaminant-free processing line is vital. Preventing a single food safety incident protects a brand from devastating recalls, legal issues, and loss of consumer trust.

Analyzing the 'Investment': Total Cost of Ownership

A comprehensive financial analysis extends beyond the initial purchase price. Processors must evaluate the Total Cost of Ownership (TCO) to understand the full financial commitment. This includes the upfront investment, ongoing operational expenses, and the often-overlooked costs of maintaining outdated processes. A thorough TCO calculation provides a clear picture of the long-term financial impact.

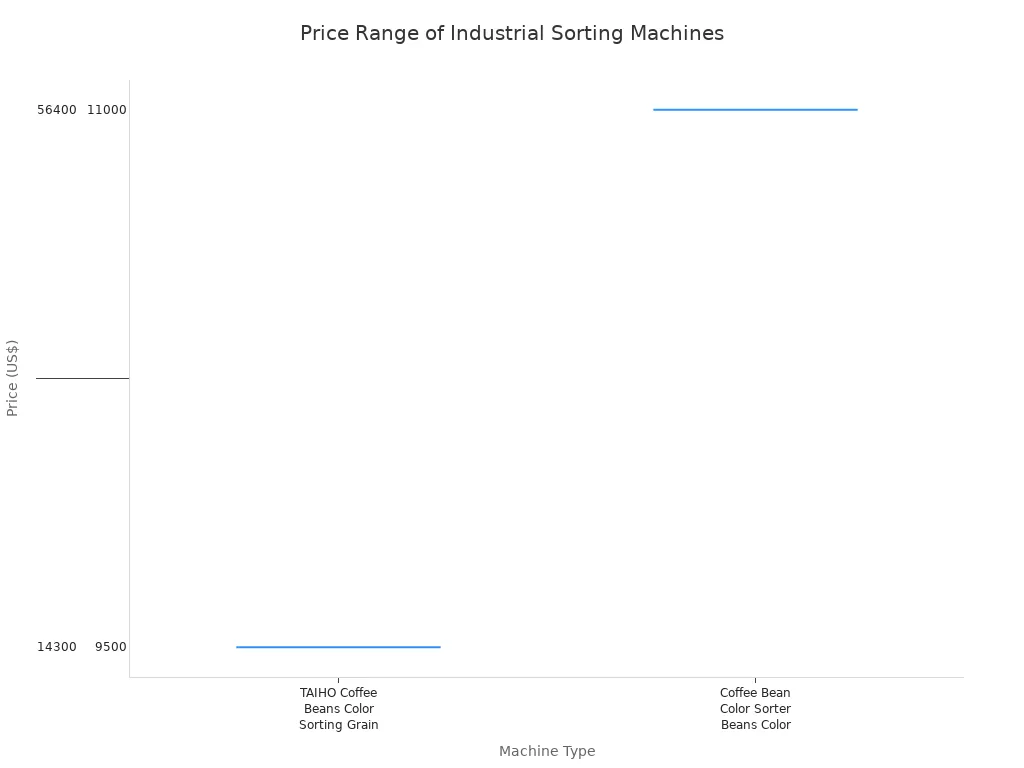

The Upfront Purchase and Installation Price

The primary investment is the capital required to purchase and install the equipment. The price of an industrial sorter varies significantly based on its capacity, technological sophistication, and features. Entry-level models may start around $5,000, while high-capacity, multi-spectral systems can exceed $50,000.

| Machine Type | Price Range (USD) |

|---|---|

| Mini Grain/Seed Color Sorter | $4,999 - $35,000 |

| Standard Coffee/Bean Sorter | $9,000 - $19,000 |

| High-Capacity Rice/Grain Sorter | $12,700 - $57,000 |

This initial outlay is the most visible part of the investment.

Ongoing Operational and Maintenance Costs

Operational costs are a recurring part of the TCO. Processors should budget for several key expenses:

- Energy Consumption: Powering the machine, its cameras, and air ejectors.

- Maintenance and Spare Parts: Regular servicing and replacement of wear-and-tear components.

- Software Updates and Support: Fees for technical support or software upgrades.

- Operator Training: Ensuring staff can operate and maintain the equipment effectively.

The Hidden Cost of Inaction

Perhaps the most significant cost is the one incurred by not investing in a modern macadamia nuts sorting machine.

This "cost of inaction" includes perpetual losses from lower kernel recovery, inflated labor expenses for manual sorting, and the risk of brand damage from inconsistent quality or food safety failures.

These ongoing inefficiencies directly erode profit margins every day a processor operates without this technology.

How a Macadamia Nuts Sorting Machine Boosts Efficiency

A macadamia nuts sorting machine enhances operational efficiency far beyond simple defect removal. It streamlines the entire processing workflow, leading to faster production, better resource management, and unparalleled consistency. These improvements directly translate to a stronger bottom line.

Achieving Higher Throughput Speeds

Automated sorters process nuts with incredible speed and accuracy. While manual sorting is slow and labor-intensive, a modern sorter can handle massive volumes. Capacities often range from 500 to over 2,000 kilograms per hour, depending on the model. This high throughput allows processors to significantly increase their output and reduce sorting time by as much as 40%. The result is a dual improvement in both production speed and sorting precision.

Reducing Food Waste and Maximizing Resources

Efficient sorting is a key component of sustainable processing. By precisely identifying and removing only defective kernels, sorters minimize the rejection of good products. This practice directly reduces food waste. Furthermore, this technology helps processors achieve sustainability goals by:

- Optimizing the use of raw materials.

- Decreasing energy consumption by removing defects before energy-intensive steps like freezing.

- Reducing water usage in subsequent washing stages.

This resourcefulness turns potential waste into valuable, saleable inventory.

Ensuring Consistent Sorting Accuracy

Automated systems deliver a level of accuracy that human sorters cannot consistently match. Advanced technologies achieve exceptional classification rates.

For example, specific sensors can identify good kernels with 97.8% accuracy and detect insect damage with 100% accuracy.

Many systems also integrate machine learning and artificial intelligence. These smart sorters continuously learn and refine their detection algorithms, improving their ability to spot imperfections over time and ensuring the final product meets a purity level of 99% or higher.

Calculating Your Specific ROI: A Step-by-Step Framework

Processors can translate the benefits of automated sorting into a compelling financial argument. A clear, step-by-step framework helps quantify the return on investment (ROI). This process moves the discussion from abstract benefits to concrete financial projections, making the investment decision straightforward.

Step 1: Calculate Annual Financial Gain

The primary financial gain comes from improved product output and value. Processors should first calculate the total annual revenue increase generated by the sorter. This calculation involves two main components.

- Increased Yield Value: Determine the additional volume of saleable kernels recovered per year. Multiply this volume by the average selling price per kilogram.

Additional Kernel Volume (kg/year) x Price per kg = Annual Yield Gain

- Premium Pricing Uplift: Calculate the extra revenue earned from selling a higher-grade product. Multiply the total volume of premium-grade kernels by the price difference between standard and premium grades.

Premium Kernel Volume (kg/year) x (Premium Price - Standard Price) = Annual Quality Gain

The sum of these two figures represents the total annual financial gain from improved production.

Step 2: Factor in Labor Cost Savings

Automated sorting drastically reduces the reliance on manual labor. This shift creates significant and predictable cost savings. To quantify this, processors must calculate the net change in labor expenses.

The most direct financial return often comes from reallocating or reducing the workforce previously dedicated to manual sorting. This single factor can justify the investment on its own.

Calculate the total annual cost of manual sorters, including wages, benefits, and associated overhead. Then, subtract the cost of the smaller team needed to operate and supervise the new equipment. The result is the annual labor cost saving.

Step 3: Determine ROI and Payback Period

With all financial inputs gathered, processors can calculate the two most important investment metrics: ROI and the payback period. The standard formula for Return on Investment is:

ROI (%) = (Total Annual Gain - Total Annual Cost) / Total Investment Cost x 100

- Total Annual Gain: The sum of financial gain (Step 1) and labor savings (Step 2).

- Total Annual Cost: The ongoing operational costs of the sorter (energy, maintenance).

- Total Investment Cost: The upfront purchase and installation price.

The payback period shows how quickly the investment will pay for itself. The calculation is:

Payback Period (Years) = Total Investment Cost / Net Annual Gain

A shorter payback period indicates a more attractive investment.

A Practical Example: ROI in Action

Let's consider a hypothetical mid-sized processor that invests $50,000 in a new macadamia nuts sorting machine. The company processes 500,000 kg of kernel annually.

| Metric | Before Sorter (Manual) | After Sorter (Automated) | Annual Impact |

|---|---|---|---|

| Saleable Yield | 92% (460,000 kg) | 96% (480,000 kg) | +20,000 kg |

| Average Price/kg | $15.00 | $15.50 (due to quality) | +$0.50/kg |

| Annual Revenue | $6,900,000 | $7,440,000 | +$540,000 |

| Manual Labor Cost | $120,000 (6 sorters) | $40,000 (2 operators) | -$80,000 |

| Sorter OpEx | $0 | $10,000 | +$10,000 |

Calculations:

- Total Annual Gain: The processor gains $540,000 in new revenue and saves $80,000 in labor costs.

Total Gain = $540,000 + $80,000 = $620,000

- Net Annual Gain: Subtract the new operational costs.

Net Gain = $620,000 - $10,000 = $610,000

- ROI (Year 1):

ROI = ($610,000 / $50,000) x 100 = 1,220%

- Payback Period:

Payback Period = $50,000 / $610,000 = 0.082 years- This is approximately 1 month.

This example demonstrates a powerful financial outcome. The investment not only pays for itself almost immediately but also generates substantial ongoing profit.

A high-tech sorter is a strategic investment that generates profit, not just an operational expense. Processors can confidently build a business case by calculating ROI based on increased yield, quality premiums, and labor savings.

Adopting this technology is a critical step toward gaining a competitive advantage in the modern macadamia market.

FAQ

What defects can a macadamia sorter identify?

Automated sorters detect a wide range of imperfections. These include insect damage, mold, discoloration, and foreign materials, ensuring a high-purity final product.

Can one machine sort different sizes of macadamia kernels?

Yes, most modern sorters are versatile. Operators can adjust settings to accommodate various kernel sizes and shapes, ensuring consistent performance across different product batches.

How much operator training is required?

Modern sorters feature intuitive interfaces. Basic operator training is usually completed within a few hours, allowing staff to manage the equipment efficiently with minimal downtime.

See Also

Essential Industrial Checkweighers for Optimal Food Plant Operations

Boosting Pharmaceutical Efficiency with Advanced Capsule Decapsulation Technology

Capsule Sorters: Key to Eliminating Defects in Pharmaceutical Production

Top Capsule Checkweighers for Prospective Buyers in the Year 2025

Evaluating Custom Cargo Lifts: Advantages and Disadvantages for Businesses