Alfalfa Seed Sorting Solutions What to Look For in 2026

Selecting the right alfalfa seeds sorting solution requires careful analysis. Growers must first identify specific contaminants, like dodder or other crop seeds, within their harvest. Next, they should evaluate sorting technologies for precision. Advanced optical sensors and AI can achieve purity levels above 99.9%. Finally, matching machine throughput to operational volume and analyzing total cost ensures a wise investment.

Note: The global alfalfa seed market is projected to reach USD 656.94 million by 2025 and is expected to grow at a CAGR of 8.8% through 2032, underscoring the increasing importance of high-quality seed production.

Key Technical Specifications for Your Alfalfa Seeds Sorting Solution

Producers must evaluate several technical specifications to find the right machine. A thorough analysis of a sorter's contaminant detection, imaging technology, artificial intelligence, and ejection mechanics will lead to a confident and profitable investment. This process ensures the chosen equipment meets both current and future purity standards.

Assessing Contaminant and Purity Goals

The first step in selecting an alfalfa seeds sorting solution is to define the problem. Growers need a clear understanding of the specific contaminants present in their seed lots. This profile dictates the level of technology required to achieve purity goals, which often exceed 99.9%.

Dodder, a parasitic plant, presents one of the most significant challenges. It severely reduces alfalfa forage yield by 50% to 80% and can halt seed production entirely. Heavy dodder infestations make seed certification difficult, forcing growers to accept lower prices for uncertified products. The weed also clogs harvesting machinery, causing operational delays and further seed loss during the cleaning process.

Beyond weeds, producers must also consider biological and genetic contaminants.

- Pathogenic Microorganisms: Raw alfalfa seeds can harbor harmful pathogens like E. coli O157:H7 and Salmonella. These contaminants pose a serious food safety risk, as they can multiply rapidly during the sprouting process. Numerous foodborne illness outbreaks have been traced back to contaminated seeds.

- GMO Contamination: For non-GMO and organic producers, the presence of genetically modified alfalfa seeds is economically devastating. Contamination can occur through pollen drift or spilled seeds, leading to the rejection of entire crops from premium markets and the loss of organic certification.

A comprehensive assessment of these threats allows a producer to set precise purity targets and identify the essential features needed in a sorting machine.

Evaluating Optical Sorting Technology

Modern sorters rely on advanced optical sensors to see what the human eye cannot. By 2026, the market will be dominated by systems that integrate multiple technologies for unparalleled accuracy. When evaluating an alfalfa seeds sorting solution, producers should look for machines equipped with the latest imaging capabilities.

Key technologies to watch for include:

- Multispectral and hyperspectral imaging

- AI-powered defect detection

- Deep learning algorithms for material classification

- Integration with the Internet of Things (IoT) for real-time monitoring

These advancements allow sorters to analyze objects based on a wide range of data points, not just color. Leading manufacturers are already implementing these features to solve complex sorting challenges.

| Company | Technology | Key Features |

|---|---|---|

| TOMRA Recycling | GAINnext (Deep Learning) | Uses AI to classify objects from sensor data, separating food-grade from non-food-grade materials. |

| Pellenc ST | CNS BRAIN (AI Module) | Combines deep learning with spectroscopy to improve sorting accuracy for complex separation tasks. |

| Steinert | UniSort Finealyse+ | Increases throughput and sorting quality for fine-grain materials using advanced sensor fusion. |

A sorter with high-resolution, multi-spectrum cameras provides the detailed data necessary for the machine's AI to make accurate decisions.

The Role of AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are the brains that power next-generation sorters. These systems are no longer just programmed; they learn. An AI algorithm analyzes data from every seed that passes its sensors, refining its understanding of what constitutes a "good" seed versus a contaminant. This continuous learning process allows the machine to identify new or unusual defects as they appear.

For example, the Merlin Ai system uses advanced learning techniques to improve the detection of subtle defects like insect damage or mycotoxins, which are becoming more common due to changing weather patterns. The AI can identify these complex issues even when the contaminant is the same size and weight as a healthy seed.

Looking Ahead: By 2026, experts predict that AI will revolutionize seed processing. A survey of agricultural professionals found that 66% believe AI-driven solutions are the future. These systems will move beyond color sorting to evaluate seed viability and overall purity, helping to maximize output and promote sustainable farming practices.

Analyzing Ejection System Precision

The final critical component is the ejection system. After the cameras and AI identify a contaminant, a high-speed ejector must physically remove it from the product stream with pinpoint accuracy. Two factors are paramount: response time and durability.

Modern ejectors operate at incredible speeds. For effective removal, a system should have a response time of 10 milliseconds or less. Top-tier models featuring maglev technology can achieve response times as low as 0.8 milliseconds, while some adaptive spraying technologies react in just 0.05 milliseconds. This speed is essential for minimizing the accidental ejection of good seeds, a factor known as the "good-in-bad" ratio.

Durability and maintenance are just as important for long-term performance. Ejector systems are sensitive to the quality of the compressed air that powers them.

Pro Tip: 💡 Always use an ultraclean, oil-free, and moisture-free compressed air supply. Regular monitoring of air quality and filter maintenance is crucial to prevent internal valve failure and ensure consistent uptime.

Common issues like air leaks or valve failures are often traced back to poor air quality or improper operating temperatures. Producers should review a manufacturer's maintenance requirements and ensure their facility can meet them.

| Fault Symptom | Common Cause | Recommended Solution |

|---|---|---|

| Ejector Air Leak | Foreign matter inside; ambient temperature below 5°C. | Ensure compressed air quality meets standards; contact service for replacement if damaged. |

| Ejector Fails to Act | Poor electrical contact; coil or PCB failure. | Check all circuit connections; contact after-sales support for professional repair. |

| Low Air Output | Air pressure is too low; pneumatic line valve is closed. | Verify the sorter's working pressure is normal; check that all air valves are open. |

A precise, fast, and reliable ejection system ensures that the intelligence gathered by the optical sensors and AI is translated into a perfectly sorted final product.

Determining Operational and Financial Viability

A technically superior machine is only a wise investment if it aligns with a producer's operational scale and financial goals. Before making a final decision, growers must conduct a thorough analysis of the sorter's capacity, long-term costs, and potential return. This evaluation ensures the chosen equipment delivers both purity and profitability.

Calculating Throughput and Capacity Needs

Matching a sorter's capacity to operational volume is a critical first step. An undersized machine creates bottlenecks and slows down the entire processing line. An oversized machine leads to unnecessary capital expenditure and inefficient energy use. Producers should calculate their required throughput in tons per hour based on peak processing demands.

Sorting machine capacities vary widely. Large-scale models, like the 5BG grain sorter, can process materials at a rated capacity of 10 tons per hour. However, this figure is often for denser grains like wheat, so adjustments are necessary for lighter alfalfa seeds. Some high-volume facilities, such as Mediterranea Sementi's flagship plant, produce 6,000 tons of premium alfalfa seeds annually, which helps illustrate the capacity required for major industrial operations. Other processing lines designed for multiple seed types might handle 800 to 1,000 bushels per hour, a rate that requires conversion to tons to compare accurately. A producer must assess their own harvest volumes to select a machine that meets their specific needs without being excessive.

Analyzing Total Cost of Ownership (TCO)

The upfront purchase price is only one part of the financial equation. A comprehensive analysis of the Total Cost of Ownership (TCO) provides a more accurate picture of the long-term financial commitment. TCO includes the initial investment plus all associated costs over the machine's lifespan.

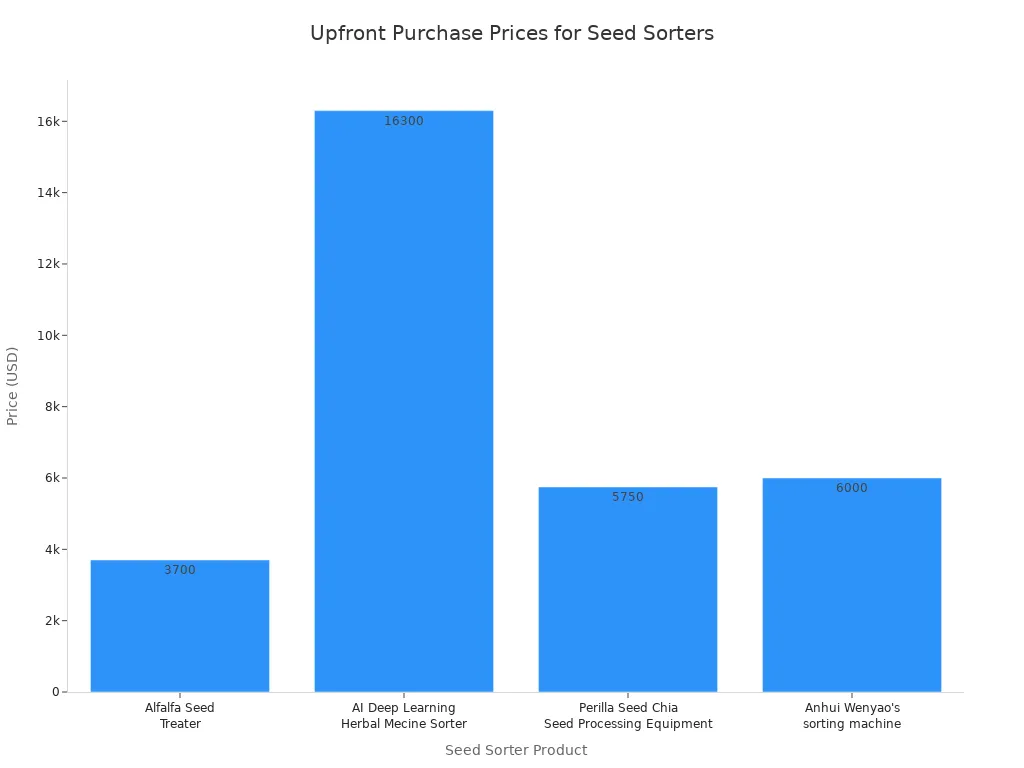

Initial purchase prices for sorters with advanced capabilities can range significantly. A mini seed color sorter might cost between $6,500 and $6,800. In contrast, a machine equipped with AI deep learning technology could be priced from $15,800 to $16,800.

Beyond the sticker price, growers must account for several other factors:

- Installation and Setup: Fees for professional installation and calibration.

- Energy Consumption: The ongoing cost of electricity to power the sorter and its compressed air system.

- Maintenance and Parts: The frequency and cost of routine maintenance and replacement parts.

- Training and Labor: The cost of training operators to use the new technology effectively. Automated sorting reduces manual labor on the packing line, but it requires skilled technicians to operate and maintain the equipment. Neglecting staff training leads to costly inefficiencies and errors.

A thorough TCO analysis helps producers avoid unexpected expenses and ensures the chosen alfalfa seeds sorting solution is financially sustainable.

Projecting Your Return on Investment (ROI)

A strong Return on Investment (ROI) justifies the capital outlay for a new sorter. The primary drivers of ROI are increased revenue from higher-purity seeds and cost savings from improved efficiency. By achieving purity levels of 99.9% or higher, producers can access premium markets, command better prices, and avoid penalties associated with contamination.

The payback period for this type of investment can be surprisingly short. For many mini seed cleaning machines, the typical ROI period ranges from just 3 to 18 months. High-efficiency models that significantly boost purity and reduce waste naturally deliver a faster payback.

Pro Tip: 💡 Use specialized financial models to get a clearer projection. While a simple calculation works, dedicated tools can provide deeper insights. The AI for Agriculture ROI Calculator helps project returns from precision farming technology, while the Seed Bank Management Calculator can quantify time savings and efficiency gains.

By projecting the ROI, producers can confidently demonstrate the financial benefits of the investment to stakeholders and secure the necessary funding.

Future-Proofing with Modularity and Support

The agricultural technology landscape is constantly evolving. Choosing a sorter that can adapt to future needs is essential for long-term success. Modularity and strong vendor support are the two pillars of a future-proof investment.

A modular design offers unparalleled flexibility. It allows a producer to upgrade components, such as sensors or AI software, without replacing the entire machine. This approach protects the initial investment and enables the operation to stay competitive.

Modular construction offers a flexible design that supports future upgrades and easy integration into new or existing processing lines.

Key benefits of modularity include:

- Cost Efficiency: A single, adaptable unit can handle various sorting tasks, reducing the need for multiple machines.

- Reduced Downtime: Standardized parts and quick-release mechanisms make cleaning and maintenance faster, minimizing production stoppages.

- Smart Integration: Modern modular systems often include IoT sensors for real-time monitoring, enabling data-driven optimization and predictive maintenance.

Finally, a reliable manufacturer is a long-term partner. Top-tier vendors provide robust support to ensure their machines perform optimally. Buyers should look for comprehensive service packages that include a strong warranty, accessible technical support, and operator training. Leading suppliers often provide a minimum 12-month warranty, which can be extended to three years, and offer 24/7 technical support with rapid response times. This level of backing guarantees that help is available when needed, maximizing uptime and protecting the investment for years to come.

Choosing the optimal alfalfa seeds sorting solution for 2026 demands a balanced review of technical precision and financial viability. Producers should prioritize systems with advanced optical and AI technology tailored to their unique contaminants. A final decision must align with throughput needs, offer a clear ROI, and include strong vendor support.

FAQ

Can a color sorter remove dodder seeds effectively?

Yes. Advanced sorters use multispectral imaging and AI to detect dodder by its unique texture and shape. This technology ensures high removal rates and superior seed purity.

What is a realistic ROI for a new seed sorter?

Producers can often see a return on investment within 3 to 18 months. Higher purity levels open access to premium markets, accelerating the payback period for the equipment.

How does AI improve sorting compared to older machines?

AI algorithms continuously learn from the seed stream. They identify new or subtle defects like insect damage, adapting in real-time to improve accuracy beyond pre-programmed sorting rules.

See Also

Essential Capsule Checkweighers for Smart Buyers to Consider in 2025

Leading Precoating Materials: Enhancing Filtration Systems for Optimal Performance in 2025

Capsule Sorters: Crucial Technology for Effective Defect Removal and Quality Control

Indispensable Industrial Checkweighers: The Top Three for Every Food Processing Plant

Ampoule Filling Production Lines: A Comprehensive Showdown of Leading Manufacturers