Traditional or AI Sorter A Head-to-Head Comparison for Soybean Seeds

An AI-powered soybean seeds optical sorter provides superior long-term value. Its advanced accuracy and adaptability maximize crop quality and yield. A traditional sorter presents a lower initial cost. It is a practical choice for operations with limited budgets or simpler sorting requirements.

Core Sorting Technology: A Head-to-Head Comparison

The core technology inside a sorter dictates its performance. Traditional and AI-powered machines approach the task of sorting soybeans from fundamentally different perspectives. This difference directly impacts accuracy, flexibility, and overall processing power.

Accuracy and Defect Detection

Accuracy is the cornerstone of effective sorting. It determines the quality of the final product and the amount of good seed lost during the process.

-

Traditional Sorters: These machines typically use standard cameras and lighting to identify defects based on pre-set color, size, and shape parameters. They perform well when sorting for obvious color differences or removing large foreign materials. However, their capability is limited. Traditional visual inspection often fails to identify subtle defects with precision due to variations in shape, color, and light reflection. This method struggles with issues like early-stage mold, hidden insect damage, or slight skin discoloration, which may not present a strong color contrast.

-

AI Sorters: An AI-powered soybean seeds optical sorter utilizes deep learning algorithms and multispectral or hyperspectral cameras. This technology goes beyond simple color. It analyzes texture, biological characteristics, and subtle patterns invisible to standard cameras. AI systems can automate the grading of soybeans by detecting a wide spectrum of issues.

- Physical Damage: Identifies broken, immature, or skin-damaged seeds.

- Contaminants: Detects and removes foreign materials like stones, dirt, or other seeds.

- Subtle Defects: Excels at finding challenging defects like internal damage or early-stage disease.

Minimizing Good Seed Loss A major drawback of less precise systems is a high false rejection rate, where good seeds are incorrectly discarded. AI sorters significantly reduce this waste. Advanced algorithms, such as classification via regression (CVR), improve accuracy in rejected seed lots. Better machine design, including belt sorters that control seed orientation, enhances imaging accuracy and further lowers the rate of false positives.

Adaptability to Seed Variations

Soybeans are a natural product with inherent variability. A sorter’s ability to adapt to these changes is crucial for maintaining consistent quality.

Traditional sorters require manual recalibration when an operator introduces a new soybean variety or when harvest conditions change. An operator must adjust the sensitivity settings for color and shape, a process that can be time-consuming and depends heavily on operator skill. Each adjustment period results in downtime and potential sorting inconsistency.

AI sorters demonstrate superior adaptability. Once trained on a diverse dataset, the machine’s neural network can recognize a vast range of variations within accepted parameters. It can differentiate between natural color variations of a healthy seed and the discoloration caused by disease. When a new defect type appears, operators can "teach" the system to identify it, continuously improving its sorting logic without extensive mechanical adjustments. This makes AI systems ideal for operations that handle multiple seed varieties or face unpredictable quality from year to year.

Operational Efficiency and Throughput

Efficiency is measured by how many tons of soybeans a machine can process per hour (throughput) and how consistently it can operate (uptime).

Traditional sorters offer reliable performance but are ultimately limited by their mechanical and computational simplicity. AI sorters are engineered for high-volume, continuous operation. The throughput difference is significant, as shown below.

| Sorter Type | Typical Throughput (tons/hour) |

|---|---|

| Manual Sorting | 0.01 - 0.015 |

| Traditional Sorter | 0.5 - 3 |

| High-Capacity AI Sorter | 2 - 20+ |

A high-resolution AI bean color sorter can process up to 2 tons per hour, while large-scale modular systems can exceed 20 tons per hour. This massive increase in throughput allows processors to handle larger volumes in less time.

Furthermore, AI systems offer exceptional reliability. Many are built with a modular design that eliminates single points of failure. If one component or module requires service, the rest of the system continues to operate at nearly full capacity, achieving close to 100% uptime. This contrasts sharply with traditional sorters, where a single part failure can halt the entire line. AI-driven predictive maintenance can also reduce fleet downtime by 50% and overall maintenance costs by up to 25%, ensuring the machine runs optimally during critical peak seasons.

Financial Breakdown: Cost vs. Return on Investment

The decision between a traditional and an AI sorter often comes down to financials. A thorough analysis of upfront costs, long-term savings, and potential revenue gains is essential for making a sound investment. The initial price tag tells only part of the story; the true value emerges over the lifetime of the machine.

Upfront Investment Costs

The initial capital required is the most significant difference between the two technologies. Traditional sorters offer a much lower barrier to entry.

-

Traditional Sorters: These machines are relatively affordable, making them accessible for smaller operations or those with tight budgets. Prices can vary based on capacity and features, but many models are available for a modest investment. For facilities processing 3-5 tons daily, machines with a capacity of 500-800kg/h offer a good balance of capital and operational cost.

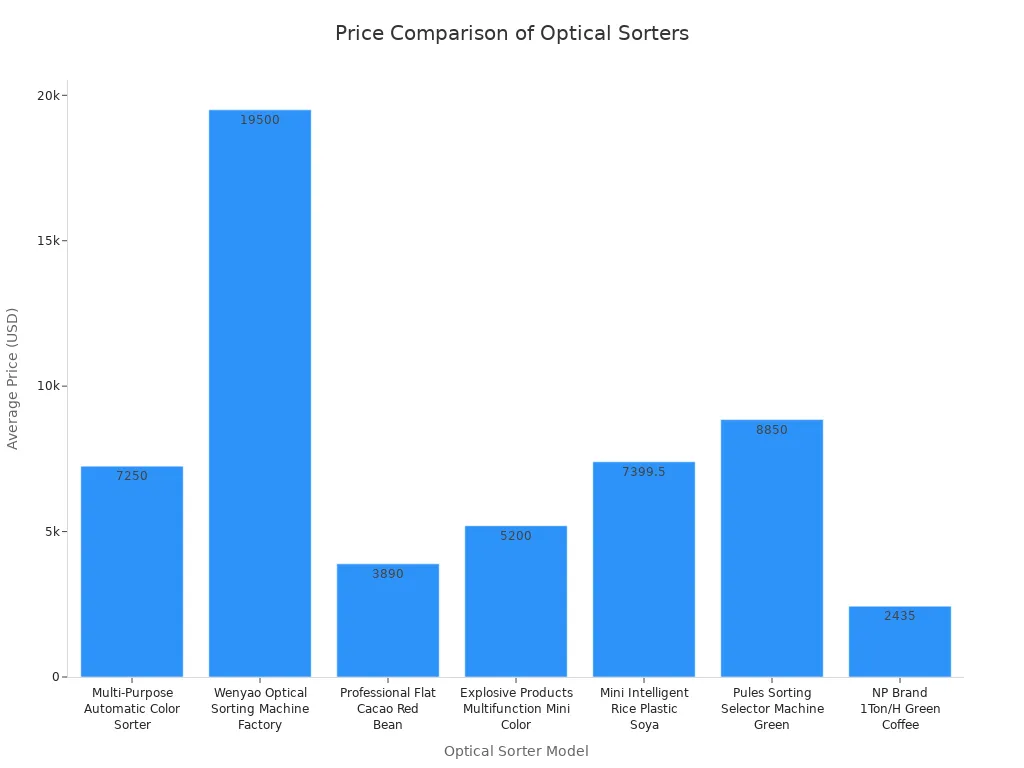

Image Source: statics.mylandingpages.co The table below shows a sample price range for various traditional sorters suitable for soybean processing.

| Product Name | Price Range |

|---|---|

| Multi-Purpose Automatic Color Sorter | $7,000 - $7,500 |

| Wenyao Optical Sorting Machine | $19,000 - $20,000 |

| Professional Flat Cacao Red Bean Sorter | $3,800 - $3,980 |

| Multifunction Mini Color Sorting Machine | $5,200 |

| Mini Intelligent Grain Color Selector | $7,299 - $7,500 |

| Pules Sorting Selector Machine | $8,800 - $8,900 |

| NP Brand 1Ton/H Green Coffee Bean Sorter | $1,935 - $2,935 |

- AI Sorters: An AI-powered soybean seeds optical sorter represents a substantial capital investment, often costing several times more than a traditional unit. This higher price reflects the advanced hardware, sophisticated software, and extensive research and development involved. However, manufacturers recognize this barrier and offer flexible financing models to make the technology more accessible.

- Robot as a Service (RaaS): This subscription-based model allows businesses to use an AI sorter on a pay-as-you-go basis. It reduces upfront costs, provides access to the latest technology without deep technical expertise, and creates predictable operational expenses for easier budgeting.

- Leasing Options: Major manufacturers like Fanuc and KUKA offer in-house leasing. Options include operational leases for short-term needs, finance leases that build equity toward ownership, and seasonal leases for managing temporary production spikes.

Long-Term Operational Savings

The higher initial cost of an AI sorter is often justified by significant long-term savings. These savings accumulate across several areas of an operation.

- Reduced Product Loss: AI sorters minimize the false rejection rate, ensuring that a higher percentage of good soybeans make it to the final product bag. This directly translates to increased saleable yield from the same harvest volume.

- Lower Labor Costs: The automation and self-calibration capabilities of AI systems reduce the need for constant operator supervision and manual adjustments. A single technician can often oversee multiple machines, freeing up labor for other value-added tasks.

- Increased Uptime: Predictive maintenance alerts and modular designs, which allow the machine to run even if one component is down, lead to nearly 100% uptime. This reliability is critical during peak processing seasons, preventing costly delays. In contrast, a traditional sorter failure can halt the entire production line.

Calculating Your ROI

Return on investment (ROI) for a sorter goes beyond simple cost reduction. It also includes new revenue opportunities created by superior product quality. An AI sorter's precision unlocks access to premium markets that are inaccessible with traditionally sorted products.

An AI sorter's ability to remove defective, discolored, or damaged beans helps producers meet the most stringent quality standards. This capability allows them to command higher prices in both domestic and export markets. The system's continuous learning refines sorting criteria, leading to the consistent, defect-free produce that premium buyers demand.

To calculate the potential ROI, an operation must consider several factors:

- Increased Revenue: Estimate the price premium achievable for higher-grade soybeans.

- Increased Yield: Quantify the value of good seeds saved from false rejection.

- Labor Savings: Calculate the cost reduction from reallocating or reducing manual sorting and supervision staff.

- Maintenance Savings: Factor in the reduced downtime and lower repair costs associated with predictive maintenance.

A simplified ROI calculation helps illustrate the financial impact: (Annual Revenue Gain + Annual Cost Savings) / Total Investment Cost. While the initial investment for an AI sorter is high, the combined financial benefits often lead to a rapid payback period and sustained profitability for years to come.

The Right Soybean Seeds Optical Sorter for Your Operation

Choosing the right sorter depends on an operation's specific goals, budget, and quality targets. The best choice balances initial cost with long-term performance and market opportunities.

When to Choose a Traditional Sorter

A traditional sorter is a practical choice for operations with straightforward sorting needs and budget constraints. These machines perform well for basic quality control. Their primary function is to choose the better soybean and remove bad material based on simple visual cues. They effectively identify different colored beans by analyzing visible light and material shape.

Simple Sorting Workflow A traditional sorter's process is direct:

- Input: Soybean Raw Material

- Accepted: Good Quality Soybeans

- Rejected: Discolored or Defective Soybeans

This capability is sufficient for producers who need to remove obvious defects and are not targeting premium markets that demand near-perfect quality.

When to Invest in an AI Sorter

An AI soybean seeds optical sorter is a strategic investment for businesses aiming for the highest quality standards. Industries like animal feed and plant-based protein require this precision to remove split or immature beans that affect final product quality. For large farms or research settings, an AI sorter acts as a "smart guardian" of seed quality, ensuring high purity.

Adopting AI technology provides significant long-term competitive advantages.

- Enhanced Market Value: AI-driven quality control ensures only premium-grade soybeans reach the market, commanding higher prices.

- Increased Profitability: AI optimizes operations and can reduce operational costs by 10-20%, boosting net profit margins.

- Sustainable Production: Advanced sorting minimizes waste by reducing good seed loss.

This technology is essential for future-proofing an operation and achieving leadership in a competitive market.

Implementation and Operational Impact

Integrating a new sorter affects more than just the processing line; it reshapes daily workflows, labor needs, and long-term maintenance strategies. The transition to either a traditional or an AI system carries distinct operational implications.

Setup and Calibration Process

The initial setup and ongoing calibration define a sorter's daily usability. A traditional sorter requires significant manual intervention. Operators must physically adjust settings for color, shape, and sensitivity, a process that relies heavily on their experience and can lead to inconsistencies. Each new batch of soybeans may require recalibration, causing downtime.

In contrast, an AI soybean seeds optical sorter automates much of this process. After an initial training phase using comprehensive data, the system's algorithms can self-calibrate. It adapts to natural variations in seed appearance without constant operator input, ensuring consistent performance and maximizing uptime.

Labor Requirements and Skill Sets

AI technology fundamentally changes the role of the human operator from manual laborer to skilled technician. While traditional sorters demand staff for supervision and frequent adjustments, AI systems operate with greater autonomy. This shift reduces direct labor costs and enhances workplace safety by minimizing repetitive strain.

However, operating an AI sorter requires a new set of competencies. Staff must evolve to meet these technical demands.

- Data Literacy: Operators need to understand data from sensors and control systems to work with engineers on identifying trends.

- AI Competencies: A basic grasp of AI concepts helps operators interpret system recommendations and make informed decisions.

- Cybersecurity Awareness: Knowledge of potential cyber threats is crucial for protecting connected operational technology networks.

Maintenance and Future Upgrades

Long-term value depends on a machine's maintenance and upgrade path. Traditional sorters often need physical component replacements to improve functionality. Upgrades can be costly and may require significant downtime.

AI sorters offer a more flexible future. Manufacturers can deploy software and algorithm upgrades remotely, enhancing sorting capabilities without new hardware. For example, some systems can receive updates that improve object detection, allowing them to distinguish new types of defects. This downward compatibility means even older machines can benefit from the latest advancements, providing continuous improvement and future-proofing the investment.

Traditional sorters meet basic needs with a low initial cost but struggle with complex defects. An AI sorter is a strategic investment that future-proofs an operation. It delivers superior accuracy and integrates with emerging technologies like:

- AI robotics and automation

- Data analytics for predictive insights

This precision gives businesses a clear competitive advantage.

FAQ

How does an AI sorter see defects differently?

AI sorters use multispectral cameras and deep learning. They analyze texture and biological traits, not just color. This technology identifies subtle defects invisible to standard cameras.

Is an AI sorter worth the high initial cost?

Yes, for many operations. AI sorters increase saleable yield and reduce labor costs. Their precision also unlocks access to premium markets, improving long-term profitability.

Will an AI sorter replace our current staff?

It changes roles rather than replacing staff. Operators transition from manual supervision to skilled technicians. They manage data and oversee a more automated, efficient system.

See Also

Capsule Sorters: Essential Technology for Flawless Product Quality and Defect Elimination

Essential Industrial Checkweighers: The Top 3 for Modern Food Processing Plants

Ampoule Filling Lines: A Comprehensive Comparison of Leading Production Manufacturers

Tablet Sampling Machines: An Ultimate Laboratory Selection Guide for Precision

Shell and Plate Heat Exchangers: Performance Comparison and Future Outlook for 2025