AI Optical Sorters A Revolution in Tropical Fruit Quality Control

A tropical fruits optical sorter employs advanced cameras and machine learning to analyze individual fruits with incredible precision. It identifies external and internal characteristics like color, ripeness, and defects with over 99% accuracy. This technology significantly improves product consistency, reduces waste, and directly boosts profitability for growers from every harvest.

How AI Optical Sorters Work to Enhance Tropical Fruit Quality

A tropical fruits optical sorter combines sophisticated hardware and intelligent software to perform quality control at an unprecedented scale. The system inspects, analyzes, and sorts fruit through a seamless, automated process. This technology moves beyond simple visual checks to conduct a deep, multi-layered analysis of every single item.

Advanced Imaging Beyond Human Vision

The process begins with advanced imaging systems that capture data far beyond the capabilities of the human eye. These sorters use a combination of powerful sensors to create a complete digital profile of each fruit. Key imaging components often include:

- High-speed smart cameras using area array CMOS image sensors.

- Multi-angle camera systems that capture the entire surface of the fruit.

- High-speed CCD industrial cameras equipped with high-definition lenses.

- Cameras that utilize multiple wavelengths of light to identify subtle defects.

One of the most powerful technologies used is hyperspectral imaging. This system combines imaging and spectroscopy to create a three-dimensional data form called a "hypercube." Instead of just seeing red, green, and blue (RGB), it analyzes a broad spectrum of light for each pixel. This allows the system to detect issues like hidden mechanical damage in a mango or persimmon long before a human eye or standard camera ever could.

Internal Defect and Ripeness Detection

Many of the most critical quality factors in tropical fruits lie beneath the surface. AI sorters use non-invasive technologies to see inside the fruit, assessing ripeness, sweetness, and hidden flaws. Near-infrared (NIR) spectroscopy is a primary method for this internal analysis. The process works in a few steps:

- An NIR emitter illuminates the fruit's surface.

- The fruit's flesh absorbs and reflects light differently based on its chemical composition.

- A spectrometer captures this unique light signature.

- Specialized software analyzes the signature to determine values for sugar content (Brix) and dry matter.

This technology allows packers to guarantee the sweetness of a pineapple or the ideal creamy texture of an avocado. AI systems can identify specific internal quality problems that would otherwise go unnoticed, such as:

- Avocados: Ultrasonic probes measure wave propagation through the fruit's flesh to monitor internal firmness and maturation.

- Pineapples: Halogen lamps and spectral sensors test the transparency of the pulp, identifying internal lesions or inconsistent sugar content.

The Core Machine Learning Engine

The data collected by the cameras and sensors flows to the system's brain: the core machine learning (ML) engine. This AI is trained to recognize patterns associated with different quality grades, ripeness levels, and defects. The engine often employs powerful algorithms to make its decisions, including:

- Artificial Neural Networks (NNs): These networks, especially Convolutional Neural Networks (CNNs), excel at learning from imaging and spectral data to identify complex patterns.

- Random Forests (RFs): This method uses multiple decision trees to classify fruit, making it highly effective and resistant to errors.

- Support Vector Machines (SVMs): SVMs are powerful classifiers that work by finding the optimal boundary to separate fruit into different categories, such as "premium grade" and "processing grade."

Training a tropical fruits optical sorter model is a meticulous process. Engineers teach the AI by feeding it thousands of labeled images. For example, a model might be trained using the following steps:

- Sample Collection: Technicians gather thousands of fruit samples, like mangoes or oleaster fruits.

- Manual Categorization: Experts manually sort the fruit into predefined quality classes based on official standards.

- Class Definition: Each class has specific criteria. Class 1 might be perfectly colored with minimal shrinkage, while Class 4 could include any fruit with visible pest damage.

- Model Training: The AI studies these categorized samples until it can accurately classify new, unseen fruit on its own.

High-Speed Automated Sorting and Grading

Once the AI engine makes a classification decision in a fraction of a second, it signals a mechanical system to physically sort the fruit. This final step happens at incredible speeds, dramatically increasing throughput compared to manual sorting. Processing speeds can be immense, though they vary by fruit type and size.

| Fruit Type | Processing Speed |

|---|---|

| Plums (Mirabelle/cherry plums) | Approximately 1 tonne per hour per lane |

| Cherry Tomatoes | 240,000 per hour |

To physically separate the fruit into different channels or bins, the tropical fruits optical sorter uses a variety of high-speed mechanisms. Based on the AI's command, the system activates the appropriate tool to direct the fruit. These mechanisms include:

- Precise air jets that puff fruit into the correct lane.

- Pusher arms that gently guide items off the conveyor.

- Drop or lift nosebars that retract to allow fruit to fall into a designated bin.

This combination of advanced imaging, rapid AI analysis, and automated mechanics enables producers to sort tons of tropical fruit per hour with unmatched accuracy and consistency.

Why a Tropical Fruits Optical Sorter is a Game-Changer

An AI optical sorter is more than just an upgrade; it represents a fundamental shift in how the tropical fruit industry approaches quality control, efficiency, and profitability. By automating and refining the sorting process, this technology addresses long-standing challenges, creating new opportunities for growers, packers, and distributors. It moves operations from a reactive model of managing defects to a proactive strategy of maximizing value from every piece of fruit harvested.

Drastically Reducing Post-Harvest Waste

Post-harvest waste is a significant challenge in the tropical fruit supply chain, often caused by spoilage, mechanical damage, and inconsistent ripening. A tropical fruits optical sorter directly confronts this issue by identifying and isolating problematic fruit with surgical precision. This early intervention prevents the spread of spoilage and ensures only viable fruit continues to the next stage.

The primary cause of spoilage in postharvest fruits is often microbe dissemination, which leads to colonization and the generation of lesions. One rotten fruit can quickly compromise an entire batch. AI sorters prevent this by:

- Early Detection: Identifying subtle signs of decay or damage invisible to the human eye.

- Immediate Isolation: Removing compromised fruit from the line before it can contaminate healthy products.

- Ethylene Management: By removing overripe or damaged fruit, the system reduces the ambient ethylene gas that accelerates the ripening and decay of surrounding fruit.

Accurate sorting is critical at every step to minimize waste. On the farm, initial sorting separates fruit by ripeness to extend shelf life. During storage and transport, regular checks remove rotten items. AI sorters automate and perfect this process, ensuring that proper culling limits food spoilage, which in turn conserves natural resources and reduces environmental pollution. This precise freshness assessment is also vital for preventing food safety issues.

Increasing Throughput and Operational Efficiency

Manual sorting is a bottleneck in fruit processing. It is slow, labor-intensive, and prone to human error and fatigue. AI-powered sorting systems shatter this limitation, delivering a massive boost to operational speed and efficiency. These systems can achieve throughput increases of up to 300% compared to traditional manual methods. This remarkable improvement comes from their ability to operate 24/7 without breaks and with unwavering accuracy.

The financial impact is substantial. Automation can reduce labor expenses by up to 40% by taking over repetitive manual tasks. In a warehouse setting, where labor can account for 50–70% of the budget, this leads to significant savings.

A Note on ROI: The initial investment for a tropical fruits optical sorter can range from 20,000 to over several hundred thousand euros. While this is a considerable cost, especially for small and medium-sized enterprises, the long-term return on investment (ROI) is compelling. By increasing efficiency, improving quality, and reducing labor needs, the technology drives long-term financial viability.

Automating the sorting process delivers cost savings in several key areas:

- Reduced Staff Headcount: A single sorting robot can often match the productivity of three to five human workers, allowing companies to reassign employees to higher-value tasks or reduce overall headcount.

- 24/7 Operation: Robots operate continuously without needing overtime pay for nights, weekends, or holidays, ensuring consistent output even during peak seasons.

- Lower Training Costs: High employee turnover in manual sorting roles requires constant recruitment and training. Once configured, an AI sorter requires minimal supervision and no retraining, cutting these recurring costs.

Unlocking Access to Premium Markets

High-end retailers and export markets have stringent quality standards that are difficult to meet with manual sorting. These markets demand uniformity in size, color, ripeness, and the absence of defects. AI sorters provide the consistency and documentation needed to confidently enter these lucrative channels.

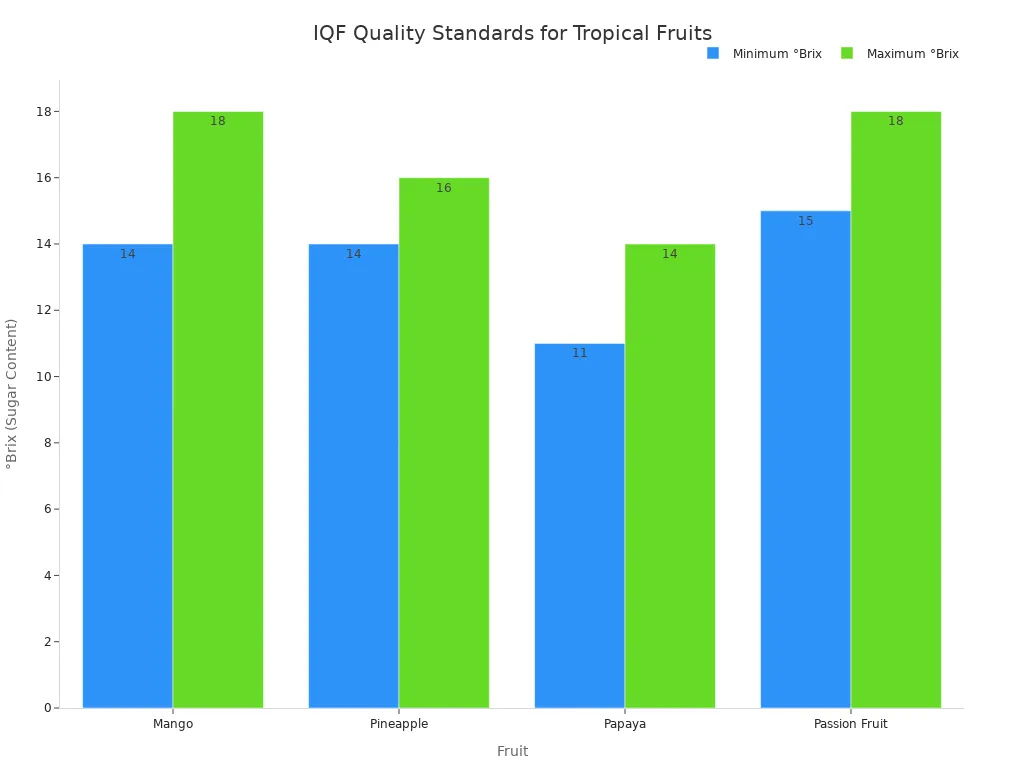

Premium markets often specify exact quality parameters. For example, the U.S. Grade Standards provide a uniform language for quality, while international buyers may require specific certifications like HACCP, GMP, or SQF. Sweetness, measured in °Brix, is another critical factor.

| Fruit | Typical Minimum °Brix for Premium Markets |

|---|---|

| Mango | 14-18° |

| Pineapple | 14-16° |

| Papaya | 11-14° |

| Passion Fruit | 15-18° |

A tropical fruits optical sorter ensures every fruit meets these precise standards. It removes the guesswork and subjectivity inherent in visual inspections. As one industry leader noted, this technology provides the confidence to meet diverse market demands. Furthermore, every sorting session can generate a detailed defect report with visuals, giving producers the analytical proof needed to justify their premium grading decisions to buyers. This level of quality control and data-driven assurance is a powerful competitive advantage.

Generating Data-Driven Harvest Insights

Beyond sorting, an AI optical sorter is a powerful data collection tool. As it analyzes each fruit, it gathers a wealth of information on characteristics like weight, shape, color, and size. This data, when aggregated, provides invaluable insights that growers can use to optimize their cultivation and harvesting practices.

By analyzing the data from a sorting run, a producer can:

- Identify Trends: Discover if a specific orchard block is producing smaller fruit or if a particular harvest time yields a higher percentage of defects.

- Optimize Harvest Schedules: Use ripeness data to pinpoint the perfect time to harvest for maximum quality and yield. This helps in better planning for resources like labor.

- Refine Cultivation Practices: Correlate sorting data with field practices. For example, if a zone shows low sugar content, a grower can investigate site-specific soil conditions or adjust fertility rates for the next season.

- Improve Profit Forecasting: With accurate data on grade distribution, producers can more reliably predict their marketable yield and revenue.

This feedback loop transforms the sorting line into an agricultural intelligence hub. Growers can use yield maps and sorting data to investigate problem areas, set realistic goals, and implement site-specific management. This data-driven approach helps optimize inputs like water and fertilizer, reducing waste and improving overall operational sustainability.

AI optical sorters are a transformative technology for tropical fruit processing. They directly address core industry challenges by improving quality, maximizing usable yield, and enhancing operational efficiency. Leading companies demonstrate the competitive edge gained from this technology.

| Company Name | AI Optical Sorter Product/Strategy | Competitive Edge Gained |

|---|---|---|

| TOMRA Systems ASA | TOMRA 5C sorter with AI and hyperspectral imaging | Enhanced accuracy, reduced food waste, improved operational efficiency |

| Bühler Group | SORTEX H SpectraVision with integrated machine learning | Unmatched precision in sorting complex food commodities |

| Key Technology | VERYX B140 with multi-spectral sensors and AI | Precision sorting for frozen food industry, reduced waste |

| Cimbria | SEA.IQ PLUS powered by BRAIN AI software | Helped customers meet regulatory demands and gain a competitive edge |

Adopting this technology is a critical step for producers aiming to secure a competitive advantage and achieve greater profitability in the global market.

FAQ

Can these sorters handle different types of tropical fruits?

Yes. Companies can train the AI models to recognize and sort various tropical fruits. Each fruit type requires a specific configuration for optimal performance and accuracy.

What is the accuracy rate of an AI optical sorter?

AI optical sorters achieve remarkable precision. These systems consistently demonstrate accuracy rates exceeding 99%. This performance significantly outperforms manual inspection methods and ensures superior quality control.

How does the technology improve food safety?

The sorters identify and remove fruit with mold, decay, or contamination. This early detection prevents spoiled items from entering the supply chain and compromising entire batches.

See Also

Essential Industrial Checkweighers: A Must-Have for Food Production Facilities

Capsule Sorters: Key to Eliminating Imperfections in Pharmaceutical Manufacturing

2025's Top Capsule Checkweighers: A Buyer's Guide for Smart Investments

Defining Pharmaceutical Checkweighers: Understanding Their Crucial Operational Features

Future of Carton Lines: Trending Folder Gluer Innovations for 2025