The Rise of AI Sorting in the Food Processing Industry

AI-powered sorting is an advanced automated process. It uses artificial intelligence and sophisticated sensors to separate food items based on complex criteria. Food processors deploy this technology, including in applications like a dried spinach sorting solution, to enhance quality, bolster safety, and improve efficiency. The market's rapid expansion highlights this trend.

- The global AI in food & beverages market was valued at over $10 billion in 2024.

- Projections estimate the market will exceed $50 billion by 2030.

- This represents a powerful Compound Annual Growth Rate (CAGR) of over 29%.

How AI-Powered Sorting Works

AI-powered sorting transforms raw data into precise physical actions through a sophisticated three-step process. This system operates at incredible speeds, making intelligent decisions that far exceed human capabilities. The entire sequence, from imaging to ejection, happens in a fraction of a second.

Data Capture with Advanced Sensors

The process begins with data collection. As food items travel on a high-speed conveyor, a suite of advanced sensors captures a massive amount of information. These are not standard cameras; they operate across various light spectrums to see what the human eye cannot. For example, a multispectral camera can detect subsurface bruises in fruit or moisture differences that indicate a poor seal on packaging. Different sensors are deployed for specific tasks.

| Sensor Technology | Primary Function |

|---|---|

| Hyperspectral Imaging | Captures detailed spectral data to find subtle defects and contaminants. |

| X-ray | Detects dense foreign materials like metal, glass, and stones. |

| Near-Infrared (NIR) | Analyzes chemical composition to determine moisture or ripeness. |

| Laser Sorters | Identify defects based on unique spectral properties for high-precision tasks. |

The AI "Brain" and Real-Time Analysis

The sensor data flows directly to the system's central processing unit—the AI "brain." This is where machine learning algorithms analyze the incoming information in real time. These algorithms are trained on vast datasets containing millions of images of both "good" and "bad" products.

The AI learns to identify defects, contaminants, or specific quality attributes with remarkable accuracy. A complex task like a dried spinach sorting solution relies on this rapid analysis to distinguish good leaves from foreign organic material.

Commonly used algorithms include:

- Convolutional Neural Networks (CNNs): Excellent for image recognition, these networks identify items and classify them based on visual characteristics like shape, size, and color.

- Support Vector Machines (SVMs): These algorithms are effective for classification tasks, helping the system make a clear "accept" or "reject" decision for each item.

Precise High-Speed Ejection

Once the AI identifies an undesirable item, it signals the ejection system. This final step happens with pinpoint accuracy and speed. A series of high-pressure air nozzles are precisely aimed at the target. The system actuates a specific nozzle, firing a puff of air to remove the single defective piece from the product stream without disturbing the surrounding good product. This entire response occurs in milliseconds. The precision of these systems is so advanced that they minimize the accidental removal of acceptable products, directly improving yield and profitability.

Key Benefits and Real-World Applications

The adoption of AI-powered sorting delivers transformative advantages across the food processing landscape. Processors gain the ability to refine product quality, strengthen safety protocols, and optimize resource management. These benefits translate directly into tangible returns, from higher profits to enhanced brand loyalty. The technology's real-world applications demonstrate its power to solve complex, long-standing industry challenges.

Achieving Unprecedented Product Quality

AI sorting systems elevate product quality to a level that manual inspection cannot match. These machines operate continuously without fatigue, eliminating the human error and inconsistency that arise during long shifts. Deep learning models analyze products with incredible detail. They recognize complex patterns and subtle imperfections that human eyes or conventional sensors would miss.

This capability allows processors to create highly specific product grades. AI systems can sort items based on subtle attributes identified through sensor fusion, such as:

- Sugar content in fruit

- Moisture levels in dried goods

- Internal bruising or defects

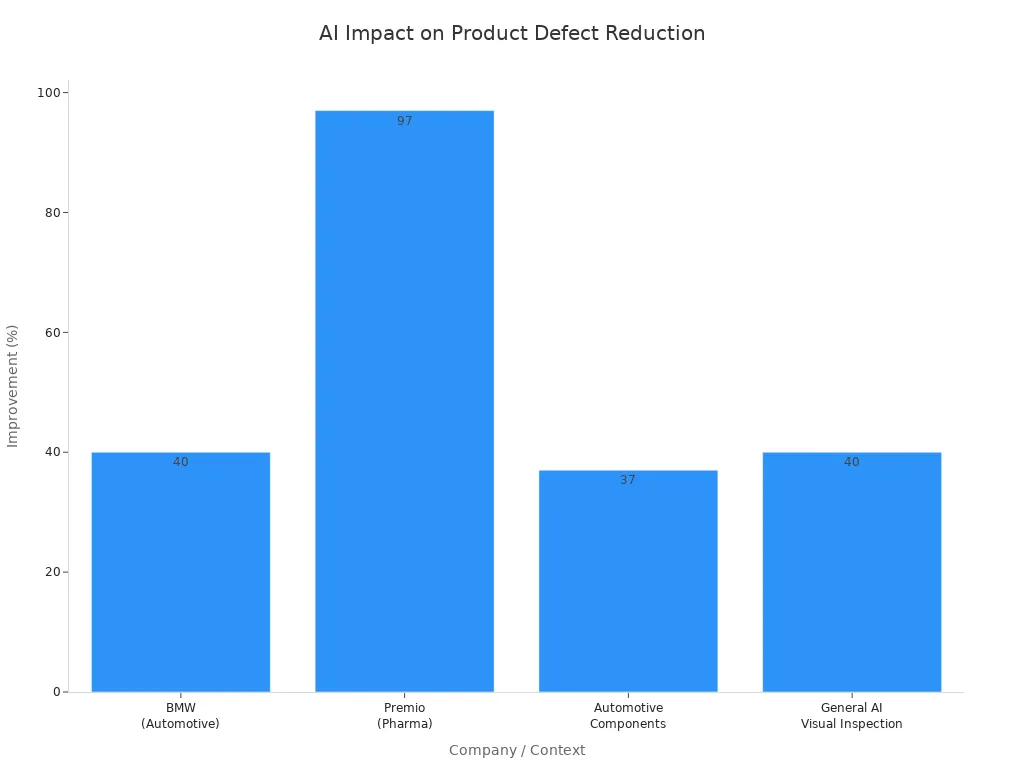

By classifying products with such precision, companies can create premium grades that command higher prices. The technology's impact on defect reduction is significant across industries, with AI visual inspection tools improving defect detection accuracy to over 98% and reducing flaws by up to 40%.

Enhancing Food Safety and Compliance

Protecting consumers from contaminants is a primary responsibility for food processors. AI sorters are a powerful line of defense against foreign materials. They excel at detecting objects that traditional systems often miss, including low-density or challenging items like:

- Wood splinters and cardboard fragments

- Clear or dark plastics

- Rubber pieces

- Glass shards embedded in wet food waste

By identifying and ejecting these hazards in real-time, AI systems drastically reduce the risk of contamination events and costly product recalls. This enhanced safety directly builds consumer trust and protects brand reputation. Companies like Coca-Cola use AI inspection to flag anomalies early, ensuring product consistency and reinforcing consumer confidence in their brand. A reliable dried spinach sorting solution, for example, must effectively remove all foreign organic and inorganic matter to be considered safe.

Increasing Yield and Reducing Food Waste

Profitability in food processing is closely tied to maximizing yield. AI sorting contributes directly to this goal in two key ways. First, the high-precision ejection systems remove only the targeted defective items. This minimizes the accidental removal of good products, a common issue with less sophisticated sorters. Studies show this precision can increase the yield of valuable products by up to one percent for potato strips and reduce the loss of valuable material on residue lines by as much as 18%.

Second, AI enables smarter utilization of all raw materials. The system can accurately categorize off-grade produce that is safe but not aesthetically perfect for the premium market. For instance, it can direct apples with minor blemishes to be used for juice or sauce instead of discarding them. This strategy maximizes the economic value of the entire harvest and significantly reduces food waste.

Improving Operational and Labor Efficiency

AI sorting systems introduce a new level of efficiency to the processing floor. These machines can process materials at incredible speeds, with modern sorters handling anywhere from 3 to 12 tons per hour. Some facilities have nearly doubled their processing output to 45 tons per hour after implementing AI technology. This massive increase in throughput allows companies to scale production without a proportional increase in facility size or labor.

Return on Investment (ROI): While the initial investment in AI can be substantial, the financial returns are often rapid. Many food processors report achieving a full ROI in under 12 months due to reduced waste, higher yields, and lower labor costs.

These systems also alleviate labor shortages and allow employees to move from repetitive manual sorting to more valuable, skilled roles like quality control management and system oversight.

A Dried Spinach Sorting Solution in Action

Sorting dehydrated leafy greens presents unique challenges. A dried spinach sorting solution must contend with subtle variations in color and texture that can indicate quality issues or the presence of foreign material. Color is a primary indicator of sensory quality, but changes due to storage and processing are often difficult for the human eye to identify.

AI, combined with hyperspectral imaging, solves this problem. The system analyzes the spectral signature of each leaf to determine its precise pigment content, including chlorophyll and carotenoids. This allows the dried spinach sorting solution to differentiate high-quality leaves from discolored ones or foreign organic material with remarkable accuracy. This advanced analytical capability ensures the final product meets stringent quality standards. The success of a dried spinach sorting solution hinges on this intelligent analysis.

Sorting Produce for Blemishes and Ripeness

For fresh produce like apples and tomatoes, appearance is critical. AI-powered computer vision systems excel at identifying a wide range of surface defects and classifying products by maturity. The technology can accurately differentiate between:

- Minor cosmetic blemishes

- Natural color variations

- Signs of actual spoilage or damage

Using Convolutional Neural Networks (CNNs), systems can achieve over 98% accuracy in detecting defects on mangoes and 99.5% accuracy in classifying spoiled figs. Furthermore, by analyzing color distribution, AI can determine the ripeness of tomatoes, allowing processors to sort them into different grades for immediate sale or further ripening. This ensures a consistent and high-quality product reaches the consumer every time.

Removing Contaminants from Nuts and Grains

Some of the most dangerous contaminants in food are completely invisible. Mycotoxins, such as aflatoxin, are carcinogenic substances produced by mold that can grow on nuts, seeds, and grains. They pose a severe health risk and are strictly regulated.

Aflatoxin B1 is one of the most potent naturally occurring carcinogens found in food. Its detection is critical for public health.

AI-powered sorters equipped with specialized optical technology can detect the unique fluorescent "fingerprint" of aflatoxin-producing mold when illuminated with a specific wavelength of light. This allows the system to identify and remove individual contaminated almonds, peanuts, or figs with surgical precision. This technology ensures the final batch complies with strict safety levels, often below 5 parts per billion (ppb), protecting consumers and the producer's brand.

AI-powered sorting is a transformative technology. It uses intelligent data analysis to automate and perfect quality control in food processing. The system delivers superior product quality, enhanced food safety, and greater operational efficiency.

Adopting AI sorting is becoming a competitive necessity for processors aiming to meet stringent quality standards.

FAQ

Can AI sorters handle different types of food products?

Yes. Processors train AI models for specific products, from produce to grains. The system adapts by using different sensors and algorithms to ensure high accuracy for each food type.

How does the system learn to identify new defects?

The system learns through machine learning. Engineers train it on large image datasets of good and bad items. It improves accuracy by analyzing new product data during operation.

See Also

Essential Industrial Checkweighers: A Must-Have for Every Food Processing Plant

Cutting-Edge Folder Gluer Innovations Shaping 2025 Carton Production Lines

Evaluating Investment in Automated Virus Sampling Tube Assembly Lines: A Key Decision

Optimizing Industrial Energy Efficiency: The Role of Condensate Cooler Technology

Top Capsule Checkweighers for Buyers to Consider in the Year 2025