Revolutionizing Rice Mills with AI Sorting Solutions

The global rice market continues its strong growth trajectory, creating new opportunities and competitive pressures for millers.

| Metric | Value |

|---|---|

| Market Size in 2023 | USD 398.26 billion |

| Market Size in 2032 (Projected) | USD 554.82 billion |

| CAGR (2024-2032) | 3.40% |

This expansion demands superior technology. An advanced rice sorting solution uses AI to deliver unprecedented accuracy and efficiency. It directly boosts profitability while solving the persistent challenges of older sorting methods, ensuring superior quality control.

The Problem with Traditional Sorting Methods

For decades, rice mills have relied on two primary sorting methods. Each approach presents significant drawbacks that impact both final product quality and the mill's bottom line. These traditional systems struggle to meet the demands of the modern market, creating bottlenecks in production and allowing unacceptable defects to pass through.

Inefficiencies of Manual Sorting

Manual sorting is an inherently slow and inconsistent process. A small processing unit often requires 10 to 15 workers dedicated solely to this task. A single worker typically sorts only 10-15 kg of rice per hour, a pace that severely limits overall throughput. This method is also prone to significant human error.

- High Defect Rates: Manual operations commonly result in defect retention rates of 7-12%.

- Reduced Yield: False rejection rates, where good grains are mistakenly discarded, average between 5-7%.

- Worker Fatigue: Accuracy can plummet by as much as 22% from a morning shift to an evening shift as fatigue sets in.

The combination of high labor costs, physical strain on employees, and inconsistent results makes manual sorting an expensive and unreliable solution.

Limitations of Basic Mechanical Sorters

Basic mechanical sorters represented an initial step toward automation, but their technology has clear limitations. These machines operate on simple color differences, which leaves them blind to many critical issues.

Conventional mechanical color sorters for rice are 'Limited to color differences, may miss same-color impurities'.

As a result, they frequently fail to detect a wide range of defects that compromise food safety and quality. These include:

- Complex defective grains like chalky, yellow, or diseased rice.

- Hazardous inorganic impurities such as glass shards, stones, and plastics.

- Organic impurities including husks and heterogeneous grains.

Furthermore, their recognition accuracy declines significantly at the high flow rates required for efficient production, creating a trade-off between speed and quality.

Why an AI Rice Sorting Solution is Superior

An AI rice sorting solution transcends the limitations of older technologies by integrating intelligent systems that see, think, and act with superhuman precision. This approach does not just improve upon existing methods; it fundamentally redefines the standards for quality and efficiency in rice processing. The system leverages a powerful combination of advanced imaging, machine learning, and automation to deliver unparalleled results.

AI-Powered Computer Vision and Machine Learning

At the core of an AI-powered system lies sophisticated computer vision. High-resolution cameras capture detailed images of every single grain. These images are then instantly analyzed by machine learning algorithms that have been trained on vast datasets of rice defects. This digital brain can identify imperfections far beyond human or basic mechanical capabilities.

These systems employ a range of powerful algorithms. For instance, research shows that Convolutional Neural Networks (CNNs) can classify rice origin and variety with an accuracy of 92.0%. Other models, like the random forest classifier, have demonstrated a 77% accuracy in identifying adulterated grains. The system continuously learns and improves, adapting to new defect types or variations in raw material, ensuring the rice sorting solution becomes more effective over time.

Note: Unlike traditional sorters that only see color, AI vision distinguishes subtle differences in texture, shape, and size. It can reliably detect chalky grains, peck damage, and even internal flaws that are invisible to the naked eye.

Advanced Sensors and Real-Time Data Analytics

AI sorters utilize a multi-sensor approach to gather comprehensive data about each grain. This goes far beyond simple color cameras. Advanced sensors provide information based on the chemical and physical properties of the material, enabling the system to make highly informed sorting decisions.

Key sensor technologies include:

- Near-Infrared (NIR) Cameras: These sensors are highly effective at separating foreign materials like stones, plastics, and sticks from good rice, even when they share a similar color.

- Indium Gallium Arsenide (InGaAs) Cameras: This technology detects defects invisible to the human eye, such as unhulled grains or shells mixed in with the final product.

- Hyperspectral Sensors: This is the most advanced technology. It identifies materials based on their unique chemical composition, allowing the sorter to remove defects that perfectly match the color of good grains.

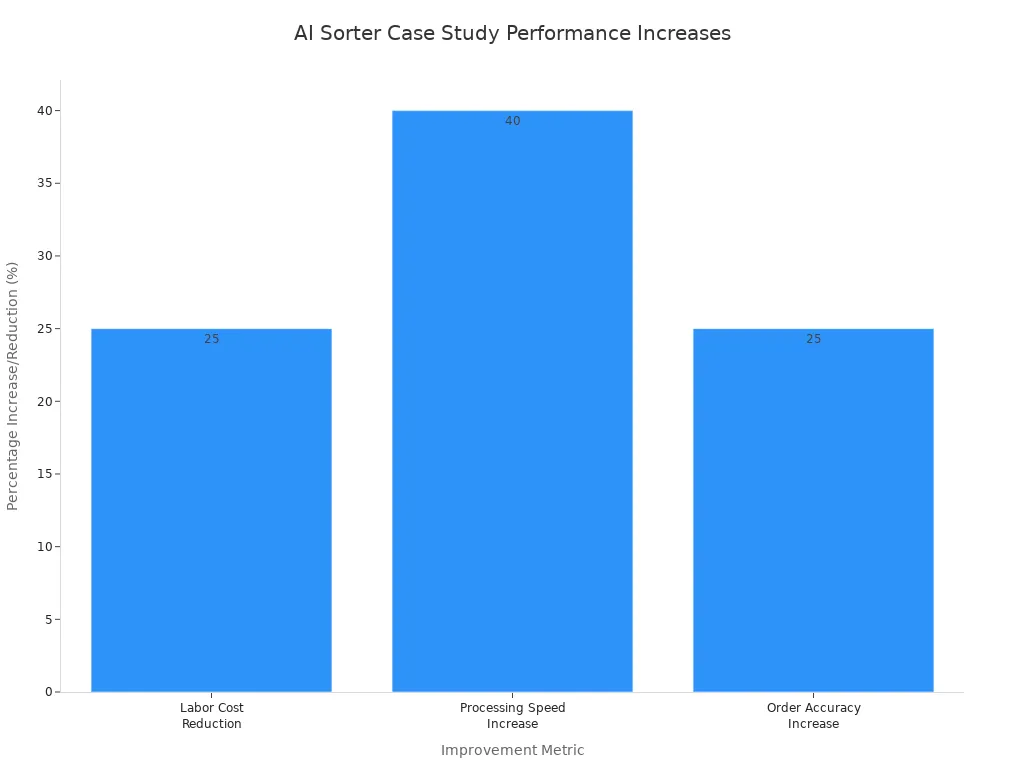

This sensor data feeds into a real-time analytics engine. The system processes information instantly, predicting and alleviating production bottlenecks before they occur. This dynamic capability allows mills to adapt to fluctuating demand and maintain peak performance. A case study of AI sorting implementation shows dramatic operational gains.

The data demonstrates how AI-driven analytics directly translates to bottom-line benefits.

| Metric Improvement | Impact on Mill Operations |

|---|---|

| Labor Cost Reduction | 25% decrease through automation |

| Processing Speed | 40% increase in throughput |

| Order Accuracy | 25% improvement from better insights |

Robotics and Automation Integration

The final piece of the puzzle is the seamless integration of robotics and automation. An intelligent rice sorting solution does not operate in a vacuum. It connects with other automated systems to create a fluid, end-to-end production line. Enhanced robotic handling and packaging systems receive the perfectly sorted rice, preparing it for shipment with minimal human intervention.

This automation drastically reduces the need for manual oversight. AI-powered systems streamline or eliminate repetitive tasks, allowing employees to focus on higher-value strategic initiatives. Key areas of improvement include:

- Data Processing: AI automates data entry and report generation, replacing manual spreadsheet management.

- Inventory Management: The system facilitates predictive ordering and demand forecasting, optimizing the supply chain.

- Process Control: When paired with Robotic Process Automation (RPA), AI can manage compliance checks and other operational workflows, adapting to changes without manual reprogramming.

By automating these labor-intensive processes, mills can significantly lower labor expenses, minimize human error, and boost overall operational efficiency. This creates a smarter, more agile, and highly scalable milling operation.

The Tangible Benefits for Your Mill

Adopting an AI-driven sorting system translates directly into measurable improvements across the entire milling operation. These systems move beyond incremental gains. They deliver transformative results that strengthen a mill's financial performance, operational efficiency, and market position. The investment in this technology yields substantial returns by optimizing core production metrics.

Achieve Up to 99.9% Sorting Accuracy

Precision is the hallmark of an AI-powered system. These platforms achieve a level of accuracy that is impossible for manual or basic mechanical sorters. The industry now expects rejection accuracies that exceed 99.9% for specific defects. AI technology meets and often surpasses this demanding standard.

- Next-generation intelligent sorters can elevate sorting accuracy from a baseline of 95% to an exceptional 99.99%.

- A Philippine Rice Mill provides a powerful case study. After implementing an AI sorter, the mill reduced residual impurities in its brown rice from 100 parts per million (ppm) down to just 5 ppm.

- This dramatic improvement in quality allowed the mill to command a 20% price premium for its product.

This near-perfect sorting capability ensures that only the highest quality grains proceed to packaging. It systematically eliminates defects, foreign materials, and impurities, guaranteeing a final product that consistently meets the most stringent quality controls.

Reduce Waste and Maximize Yield

Every grain of rice counts. A key financial benefit of superior accuracy is the drastic reduction in waste. Traditional sorting methods often have high false rejection rates, where perfectly good grains are mistakenly discarded along with defects. This directly erodes a mill's yield and profitability.

An AI rice sorting solution minimizes these losses by making highly precise distinctions between good grains and actual defects. By reducing the false rejection rate, mills can recover a significant percentage of product that would have otherwise been lost, directly boosting the total saleable yield from every batch.

This optimization has a powerful compounding effect. Saving even a small percentage of yield on every ton of processed rice translates into substantial revenue gains over the course of a year. Maximizing output from the same amount of raw material is one of the most efficient ways to increase profitability.

Increase Throughput and Productivity

AI-powered sorters operate at a speed and consistency that manual labor and older machines cannot match. They process a continuous, high-volume flow of rice without fatigue or a decline in performance. This capability allows mills to significantly increase their overall throughput. The integration of AI drives major financial and operational gains across the manufacturing process.

| Impact Area | Reported by Manufacturing Executives |

|---|---|

| Decreased Costs | 61% |

| Increased Revenues | 53% |

| Revenue Increase >5% | Over 33% |

These technologies boost productivity beyond the sorting stage. AI helps bolster production planning and scheduling by predicting potential bottlenecks before they occur. It provides end-to-end visibility into the supply chain, identifying opportunities for improvement and streamlining operations. This cognitive automation sifts through vast amounts of data to provide actionable insights, leading to smarter, faster, and more profitable decision-making.

Enhance Final Product Quality and Market Value

Ultimately, the quality of the final product determines a mill's brand reputation and market access. Consistently delivering clean, uniform, and safe rice builds consumer trust and loyalty. This superior quality is a prerequisite for entering lucrative premium and export markets. Academic studies show that wealthier nations tend to import higher-quality goods, making product excellence a gateway to global trade.

Investing in advanced sorting technology helps mills meet strict international regulatory standards. While compliance involves costs, these are offset by long-term benefits.

| Market Segment | AI Sorting Application | Key Benefits |

|---|---|---|

| High-Value Exports | Internal and external defect removal | Premium pricing, strong brand differentiation |

| Supermarkets/Retail | Upstream quality control for uniformity | Enhanced brand reputation, customer satisfaction |

A stronger brand reputation, fewer product recalls, and improved access to high-value export channels are direct results of superior quality control. For rice millers, a commitment to quality through technology is crucial for market penetration and sustainable growth in a competitive global landscape.

The Future of Smart Rice Milling

The integration of AI extends far beyond sorting, paving the way for a new era of intelligent milling operations. These future-focused technologies promise to eliminate inefficiencies, enhance transparency, and create fully automated ecosystems. The smart rice mill is no longer a distant concept; it is the next evolutionary step for the industry.

Predictive Maintenance for Zero Downtime

AI systems are transforming equipment maintenance from a reactive to a proactive process. Smart sensors continuously monitor machine performance, tracking parameters like temperature and vibration. AI models analyze this data to forecast potential equipment failures before they happen. This predictive capability allows mills to schedule service preemptively, drastically reducing costly operational disruptions. Food processing facilities implementing this strategy have reported remarkable results, cutting unplanned downtime by 30% to 50%. This shift minimizes maintenance expenditures and maximizes operational uptime.

Full Supply Chain Integration with IoT

The Internet of Things (IoT) connects the entire rice journey, from the farm to the final consumer. This integration creates unprecedented transparency and traceability.

IoT sensors and digital records provide complete farm-to-fork visibility. This digital trail supports compliance with global standards, mitigates risks from contamination, and builds consumer trust by validating ethical sourcing claims.

Through GPS plot mapping and digital batch coding, every package of rice can be traced back to its origin. This capability is essential for meeting retailer expectations, reducing the risk of shipment rejections, and enhancing brand competitiveness in a global market.

The Rise of the Fully Autonomous Mill

The ultimate goal is the fully autonomous, or "lights-out," mill. This facility operates with minimal human intervention, leveraging a suite of interconnected technologies.

- AI-Powered Machinery: Self-adjusting whiteners and sorters optimize settings in real-time for consistent quality.

- Robotics and Automation: Automated systems handle tasks from cleaning and grading to polishing and packaging.

- Integrated Data Platforms: Centralized systems like Bühler Insights use data from inline sensors to provide actionable analytics, enabling the entire mill to function as a single, intelligent organism.

This data-driven approach moves operations from corrective to proactive management, creating a new standard for efficiency and quality.

AI technology represents a fundamental shift in milling, directly linking innovation to greater efficiency and profitability. This advanced rice sorting solution offers a clear return on investment, with large mills potentially saving millions annually through reduced waste and higher yields.

Adopting these systems is essential for mill owners to remain competitive and satisfy the global demand for high-quality rice.

FAQ

How does the AI sorter handle different rice varieties?

The system uses machine learning. It trains on new datasets to recognize and sort multiple rice varieties. This allows it to adapt to different products and defect types effectively.

What does the implementation process involve?

Professional teams manage installation and calibration. They integrate the system into the existing production line. This process minimizes operational disruption and ensures a seamless transition for the mill.

Can the AI sorting system be updated over time?

Yes. The system receives software updates to improve its algorithms. These updates expand its defect detection library, ensuring the technology remains current and performs at its peak.

See Also

Essential Industrial Checkweighers: A Must-Have for Modern Food Production Facilities

Innovative Folder Gluer Advancements Shaping Carton Packaging Lines by 2025

Evaluating Investment in Automated Assembly Lines for Virus Sampling Tubes

Discovering Premier Suppliers for X-Ray Inspection Equipment in China

Key Capsule Checkweighers for Pharmaceutical Buyers to Evaluate in 2025