How AI Boosts Efficiency in Modern Oat Sorting

The global oats market shows significant growth, increasing the demand for high-quality products. Artificial Intelligence offers a modern oats sorting solution. It uses high-speed cameras and machine learning to identify defects with exceptional accuracy. This technology elevates quality standards to meet consumer expectations in this expanding industry.

| Region/Entity | Metric | Value | Year |

|---|---|---|---|

| Global Oats Market | Value | USD 5.6 Billion | 2024 |

| Global Oats Market (Expected) | Value | USD 6.6 Billion | 2033 |

| European Union | Production | 5.39 million metric tons | 2023 |

| Canada | Share of worldwide exports | Over 62% | 2020 |

From Manual Labor to Intelligent Automation

The Limits of Traditional Sorting

Historically, oat processors relied on manual labor and basic mechanical sorters. These methods are slow and inconsistent. Human inspectors experience fatigue, leading to errors and variable quality. Mechanical systems can only sort by simple metrics like size or density. Neither approach can effectively detect microscopic threats. Raw oat harvests often contain dangerous mycotoxins produced by fungi. These toxic compounds are invisible to the naked eye.

Common Invisible Threats in Oats:

- Regulated Mycotoxins: Aflatoxins (AFB1), deoxynivalenol (DON), and ochratoxin A (OTA).

- Frequently Detected Mycotoxins: HT-2, T-2, and MPA.

- Emerging Mycotoxins: Beauvericin (BEA) and sterigmatocystin (STER).

Traditional sorting methods cannot remove these hidden dangers, posing a significant risk to food safety and public health.

How AI Delivers a Superior Oats Sorting Solution

Artificial intelligence provides a modern oats sorting solution that overcomes these limitations. AI systems use advanced imaging technologies to analyze each oat kernel with incredible precision. High-resolution cameras detect subtle discoloration and breakage that human eyes miss. Near-infrared (NIR) sensors can even identify internal defects related to moisture or fungal contamination.

This technology dramatically improves efficiency and safety. An AI-powered oats sorting solution achieves up to 99.9% accuracy, significantly reducing food waste by minimizing the misclassification of good grains. Processors can see throughput increases of up to 300% compared to conventional methods. This intelligent automation ensures that only the highest quality, safest oats reach the consumer, setting a new standard for the industry.

Key AI Technologies and Their Impact

Artificial intelligence integrates several advanced technologies to revolutionize oat processing. These systems combine powerful imaging with intelligent decision-making. This synergy creates a sorting process that is faster, more precise, and safer than ever before. The core components are computer vision, machine learning, and the tangible benefits they produce.

Computer Vision and Hyperspectral Imaging

Computer vision gives machines the ability to "see" and interpret the physical world. In oat sorting, this technology acts as the system's eyes. High-definition cameras capture detailed images of every kernel, but the true innovation lies in hyperspectral imaging (HSI). HSI technology goes beyond what the human eye can perceive. It analyzes how oats interact with light across hundreds of spectral bands.

Fungal contamination denatures chemical nutrients inside the oat kernels. This process causes significant alterations in their hyperspectral characteristics. HSI captures this chemical reflectance data, allowing the system to differentiate healthy oats from contaminated ones. For detecting specific threats like T-2 and HT-2 mycotoxins, Near-Infrared (NIR) hyperspectral imaging uses key wavelengths at 1038 nm, 1110 nm, and 1393 nm to identify these invisible dangers with remarkable precision.

Note: The effectiveness of HSI is well-documented. This technology is highly suitable for discriminating against fungal damage at industrial entry points.

- Classification accuracy for identifying fungal-damaged kernels often exceeds 90%.

- Classification accuracies for mycotoxin-contaminated kernels are consistently above 80%.

This level of detail ensures that defects, contaminants, and chemical irregularities are identified instantly.

Machine Learning for Real-Time Decisions

Machine learning (ML) algorithms are the "brain" of the AI-powered oats sorting solution. These algorithms process the vast amount of data generated by the imaging systems. They make split-second decisions to accept or reject each individual kernel. A key advantage of ML is its ability to learn and adapt, even to new or unusual contaminants.

Processors train these models using unsupervised learning methods.

// Example of an unsupervised learning approach

1. Train the model exclusively on data from 'normal,' high-quality oat batches.

2. The model learns the typical patterns and characteristics of good oats.

3. It then identifies any kernel that deviates from this learned pattern as an anomaly.

Techniques like Autoencoders (AEs) and One-Class Support Vector Machines (OCSVMs) excel at this task. Autoencoders learn to reconstruct normal data and flag inputs with high reconstruction errors as defects. OCSVMs learn a boundary around normal data; any data point falling outside this boundary is classified as an anomaly. This approach allows the system to identify previously unseen threats without being explicitly trained on them.

Measurable Gains in Speed, Quality, and Safety

The integration of AI technologies delivers significant and quantifiable improvements across the board. Processors gain a competitive edge through enhanced efficiency and a stronger commitment to food safety. AI sorting directly contributes to meeting rigorous international standards, such as HACCP (Hazard Analysis and Critical Control Points) and GFSI (Global Food Safety Initiative).

This advanced technology strengthens food safety systems by ensuring critical control points are more effectively monitored and managed. By automating inspection, AI provides a robust defense against contamination reaching the consumer. The primary benefits include:

- Enhanced Detection: 🔎 AI algorithms identify subtle defects, foreign materials, and chemical contaminants that human inspectors and older machines easily miss.

- Reduced Human Error: 🤖 Automation minimizes risks associated with fatigue, inconsistency, and human oversight in the sorting process.

- Real-time Monitoring: 📊 AI systems provide continuous data on product quality, allowing for immediate process adjustments and interventions.

- Improved Traceability: 🔗 Advanced sorting systems can integrate with traceability platforms, creating detailed records of product quality throughout the supply chain.

These gains in speed, precision, and safety establish a new benchmark for the food processing industry.

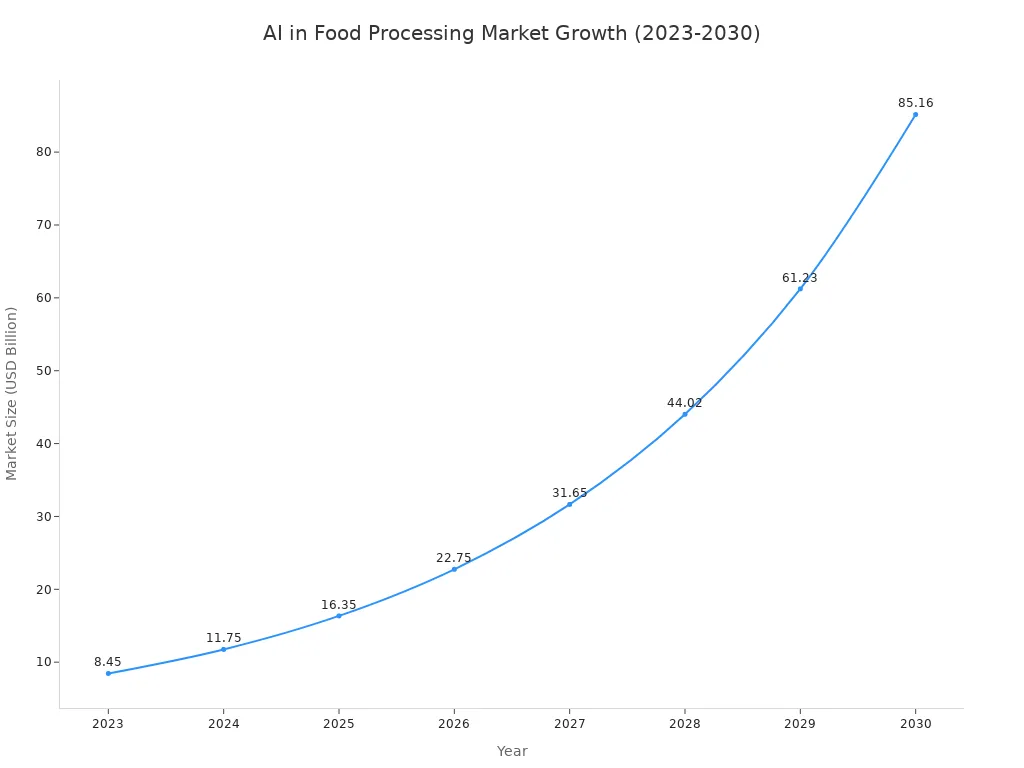

Artificial intelligence elevates the modern oats sorting solution. It guarantees superior product quality and safety through unmatched speed and precision. This technology is now an essential tool for the entire food supply chain, expanding into predictive analytics. The market's rapid growth reflects this industry-wide adoption.

FAQ

Is AI sorting affordable for smaller oat processors?

While initial costs are higher, AI systems reduce waste and increase throughput. This provides a strong return on investment, making the technology increasingly accessible for various processors.

How difficult is it to implement an AI sorting system?

Specialized providers manage installation and initial model training. They deliver a turnkey solution. This minimizes operational disruption and ensures a smooth integration into existing production lines.

Can AI systems adapt to new types of defects?

Yes. Machine learning models continuously learn from new data. They can identify previously unseen anomalies without explicit reprogramming, ensuring long-term effectiveness against emerging threats.

See Also

Optimizing Pharmaceutical Production: Modern Capsule Decapsulation Machines Boost Efficiency

Essential Industrial Checkweighers: The Top 3 for Food Processing Plants

Boosting Industrial Performance: The Role of Plate Air Preheaters

Capsule Sorters: Key Devices for Effective Defect Removal and Quality Control

Enhancing System Performance: Three Innovations in PHE Plates for 2025