AI Mixed Vegetables Optical Sorter A Simple Guide to Better Quality

An AI mixed vegetables optical sorter delivers superior accuracy and flexibility over traditional models. These intelligent systems achieve up to 95% detection accuracy, identifying subtle defects and foreign materials that older systems miss.

This precision leads to reduced food waste and can increase overall yield by as much as 20%, significantly enhancing a company's brand reputation.

Sorting Accuracy: Traditional vs. AI Sorters

Sorting accuracy is the defining factor that separates good product from great product. The technology a processor uses directly impacts final quality, waste levels, and profitability. While traditional sorters have served the industry well, AI-powered systems represent a monumental leap in precision.

Traditional Sorters: Color and Shape Basics

Traditional optical sorters operate on a straightforward principle: they use cameras and lighting to evaluate products based on predefined color and shape parameters. For simple, high-contrast sorting tasks, these machines are highly effective. They excel at removing distinctly off-color items or foreign material that does not resemble the target product.

For example, when sorting uniform products like legumes, these systems demonstrate impressive performance. They reliably remove obvious contaminants from the main product stream.

Note: Industrial sorters achieve high Correct Classification Rates (CCR) for legumes, often exceeding 99%. This high accuracy is due to the clear visual differences between the product and common contaminants.

The table below shows the average CCR for separating contaminants from different types of legumes, illustrating the capability of traditional sorters in ideal conditions.

| Legume Type | Contaminant | Average Correct Classification Rate (CCR) |

|---|---|---|

| Broad bean | Contaminant | 99.44% |

| Lentil | Contaminant | 99.67% |

| Chickpea | Contaminant | 99.36% |

However, their reliance on rigid, pre-set rules becomes a significant limitation when dealing with complex mixed vegetables or subtle defects. These systems struggle when a defect or contaminant shares a similar color and shape profile with the good product.

This limitation is especially dangerous when toxic weeds are present.

- Toxic plants like Datura stramonium (thorn apple) can closely resemble green beans or spinach after processing.

- Blanching or cutting vegetables often removes the distinct visual cues of these weeds, making shape-based detection ineffective.

- The system cannot distinguish between a piece of carrot and a similarly colored piece of plastic without more advanced analytical capabilities.

AI Sorters: Learning to See the Unseen

AI sorters move beyond simple color and shape detection. They use machine learning algorithms and advanced imaging to analyze products with near-human intelligence. Instead of following rigid rules, an AI mixed vegetables optical sorter learns from vast datasets to identify what constitutes a "good" product versus a "defective" one.

This technology addresses the shortcomings of manual inspection, which is often subjective, slow, and prone to error from worker fatigue. AI introduces a level of consistency and precision that was previously unattainable. In a case study on tomato processing, an AI-powered sorter increased marketable yield by a remarkable 25% by minimizing the rejection of good produce and identifying defects with superior accuracy.

AI systems excel at detecting subtle and complex issues that traditional sorters miss, including:

- Subtle Defects: Bruises, insect damage, and early-stage rot that only present minor discoloration or textural changes.

- Foreign Materials: AI can identify a wider range of foreign objects, even those with similar colors to the vegetables. It can distinguish between a green bean and a piece of green plastic, or a corn kernel and a piece of cardboard.

- Camouflaged Contaminants: The system can identify low-density materials like wood, rubber, and plastic that are often invisible to X-ray systems.

A leading frozen foods company provides a powerful example. By implementing an AI vision system for sorting corn, the company boosted its pick rates by 27% and projected savings of over $300,000 in five years. The AI overcame the failures of a previous automated system that struggled with positional data, demonstrating its ability to adapt in real-time and drastically reduce product waste. This intelligent analysis allows processors to guarantee a higher standard of quality and safety for their final product.

Operational Efficiency and Throughput

In food processing, speed is critical. Processors must move large volumes of product quickly to meet demand. However, throughput should never come at the expense of quality. This is where the operational differences between traditional and AI sorters become clear.

Traditional Sorters: Speed with Compromises

Traditional optical sorters are built for speed. They can process high volumes of vegetables, which is essential for large-scale operations.

| Criteria | Traditional Optical Sorting |

|---|---|

| Speed (tons/hour) | 3–15 |

This high throughput, however, often involves a trade-off. At maximum speeds, the accuracy of these systems can decline, leading to a higher rate of false rejects. Good products are mistakenly discarded along with defects. This happens because their rigid systems struggle with variables like belt speed fluctuations or dust in the processing environment. Measurement errors increase as speed rises, causing the system to misidentify acceptable products.

This compromise means processors must choose between maximizing speed and minimizing product waste, directly impacting profitability.

AI Sorters: Maximizing Speed and Accuracy

AI sorters eliminate the need to compromise between speed and accuracy. They leverage a combination of powerful technologies to maintain precision even at the highest processing speeds. This allows businesses to maximize their throughput without sacrificing quality.

Key technologies enabling this performance include:

- Advanced AI Models: These systems use sophisticated models that continuously learn to identify defects, sizes, and shapes with incredible accuracy.

- High-Performance Computing: Specialized hardware processes image data hundreds of times faster than previous technologies, allowing for real-time analysis on fast-moving lines.

- Advanced Camera Systems: High-resolution cameras capture detailed images, enabling the AI to detect even the smallest or most complex features on each item.

These components work together, allowing the sorter to make intelligent decisions in milliseconds. The result is a system that not only matches the speed of traditional sorters but also drastically reduces false rejects, boosting overall yield and efficiency.

Flexibility and Adaptability in Processing

The modern food processing environment demands equipment that can handle diverse products and changing conditions. Flexibility is no longer a luxury; it is a core operational requirement. AI and traditional sorters offer vastly different capabilities in this area.

Traditional Sorters: Rigid, Pre-Set Rules

Traditional sorters operate using fixed parameters programmed by an operator. This rule-based approach works well for uniform products but lacks the flexibility needed for complex sorting tasks. These systems struggle when sorting criteria are not straightforward. For example, they are ineffective in situations where:

- Elements lack a reliable comparison function, making a clear "good vs. bad" decision impossible.

- Comparisons are computationally expensive or impractical to perform for every item.

- It is impossible to compare all items against all criteria, especially with large data volumes.

This rigidity means that changing from one product mix to another requires significant downtime. An operator must manually recalibrate the machine, a process that is both time-consuming and prone to human error. Each new product or seasonal variation requires a new set of rules, limiting operational agility.

AI Sorters: Dynamic Learning and Quick Changeovers

AI sorters introduce a new level of adaptability through dynamic learning. These intelligent machines process food with an understanding of natural variations in shape and seasonality. Advanced AI systems incorporate self-learning algorithms that continuously improve their accuracy. This inherent ability allows them to handle evolving product characteristics by refining sorting criteria based on new data.

This means an AI sorter automatically adjusts to the subtle differences between an early-season carrot and a late-season one without needing manual intervention. 🥕

Furthermore, AI enables rapid changeovers between different products. Instead of complex reprogramming, an operator can simply select a pre-trained model from a library. The system is ready to sort a new type of vegetable mix in minutes, not hours. This capability allows processors to respond quickly to market demands and maximize production uptime, making their operations far more agile and efficient.

The Financial Picture: Cost vs. ROI

Adopting new technology always involves a careful financial evaluation. While an AI sorter represents a significant upgrade, processors must weigh its initial price against its long-term value. The financial benefits of AI extend far beyond the initial purchase, creating a compelling return on investment (ROI) through enhanced efficiency, quality, and yield.

Upfront Investment and Long-Term Costs

The initial capital expenditure for an AI optical sorter is higher than for a traditional machine. Even compact systems can require an upfront investment of $150,000 to $300,000. This cost can be a barrier for smaller processors. Recognizing this, some equipment manufacturers offer financing or leasing options to make the technology more accessible and mitigate the impact of a large one-time expense.

However, the total cost of ownership includes more than just the purchase price. Long-term operational costs are a critical part of the financial picture. Businesses should budget for ongoing AI system maintenance to ensure peak performance.

Most businesses can expect to budget $650 to $4,700 monthly for comprehensive AI maintenance. This figure typically represents 15-25% of the initial implementation cost.

These recurring expenses often include:

- Software and Licensing: Monthly fees for software, cloud hosting, and third-party integrations can range from $250 to over $1,200.

- Vendor Support: Support plans from the manufacturer usually cost 15-25% of the annual licensing fees.

- System Upgrades: Periodic hardware or software upgrades may cost 10-20% of the original implementation price annually.

- Data and Training: Costs also arise from data management, employee training, and retraining the AI algorithms as machinery ages or product conditions change.

Calculating Your Return on Investment

Calculating the ROI for an AI sorter provides a clear measure of its financial impact. The standard formula is straightforward:

ROI = (Net Profit – Costs) / Costs × 100

To use this formula effectively, a business must track the right Key Performance Indicators (KPIs). These metrics quantify the improvements the AI sorter brings to the operation.

- Operational Efficiency KPIs:

- Production throughput and cycle time

- Overall Equipment Effectiveness (OEE)

- Energy consumption

- Quality Control KPIs:

- Defect detection and scrap rates

- First-pass yield (the percentage of products made correctly without rework)

- Customer satisfaction scores and reduced complaint rates

- Financial Impact KPIs:

- Labor efficiency improvements

- Cost savings from reduced waste and rework

One of the most significant contributors to ROI is the dramatic reduction in false rejects. Traditional systems often mistakenly discard good products, creating immense waste and requiring costly manual re-inspections. AI systems minimize these errors, directly boosting yield and profitability. An automated system that optimizes the rejection process prevents slowdowns and bottlenecks, ensuring a continuous production workflow.

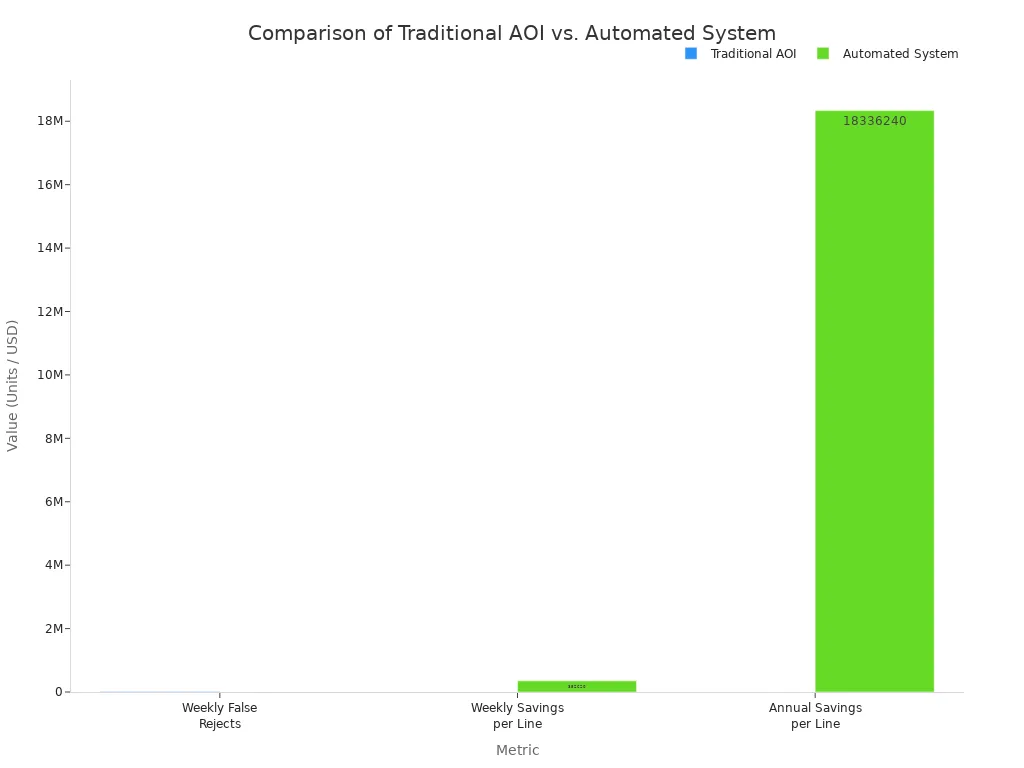

The financial impact of reducing false rejects is staggering. Data shows that an automated system can reduce false rejects from 12,000 units per week to just 246.

This level of precision translates into massive savings.

| Metric | Traditional AOI | Automated System |

|---|---|---|

| Weekly False Rejects | 12,000 units | 246 units |

| Weekly Savings per Line | $0 | $352,620 |

| Annual Savings per Line | $0 | $18,336,240 |

This improvement in yield consistency leads to a remarkably fast payback period. While other major food processing equipment may take years to pay for itself, many operators report a full return on their AI sorter investment in under two years. Some have even achieved it in less than 12 months, making it one of the most impactful capital investments a processor can make. 💰

Making the Right Choice for Your Business

Deciding between traditional and AI technology depends on a company's specific operational needs and strategic goals. The right choice balances current requirements with future ambitions.

When to Stick with Traditional Sorters

A traditional sorter remains a practical and cost-effective choice for certain operations. Businesses with low-volume production lines or those processing a single, uniform product may not require AI's advanced capabilities. For example, harvesting vegetables within a narrow maturity range significantly reduces the need for extensive color sorting. In these scenarios, a standard machine provides sufficient quality control without the larger capital investment. It is an efficient tool for simple, high-contrast sorting tasks where product consistency is already high.

When to Upgrade to an AI Mixed Vegetables Optical Sorter

An upgrade becomes a strategic necessity for businesses aiming for premium markets and operational excellence. An AI mixed vegetables optical sorter delivers the precision required to meet strict international quality regulations. This capability is crucial for securing high-value contracts. For instance, a mid-sized cooperative invested in advanced sorting to meet European export requirements. The system achieved over 99% purity rates, helping them secure new buyers in global markets.

A business should upgrade when its goals include:

- Entering premium export markets with stringent quality demands.

- Ensuring superior product consistency to build brand leadership.

- Processing complex product mixes with maximum accuracy and minimal waste.

Ultimately, investing in an AI mixed vegetables optical sorter is a forward-thinking move for companies focused on growth, safety, and future-proofing their operations.

AI optical sorters represent a significant leap forward, moving beyond simple color sorting to intelligent defect analysis that identifies subtle texture variations.

For businesses focused on premium quality and operational efficiency, investing in AI technology is a strategic move that builds consumer trust and enhances brand reputation.

The ability of an AI mixed vegetables optical sorter to handle complex tasks makes it the clear choice for future-proofing any processing line.

FAQ

What is the main advantage of an AI sorter?

AI sorters use machine learning to identify complex defects beyond simple color and shape. This intelligence provides superior accuracy for sorting mixed vegetables and reducing food waste.

How quickly can a business see a return on investment?

Many businesses report a full return on investment in under two years. Some achieve it in less than 12 months due to increased yield and reduced waste. 💰

Does an AI sorter require specialized staff to operate?

Modern AI sorters feature user-friendly interfaces. Operators can easily select pre-trained sorting models for different products, minimizing the need for extensive technical expertise or complex programming.

See Also

Capsule Sorters: Essential Technology For Efficient Defect Elimination In Production

Essential Industrial Checkweighers: A Must-Have For Every Modern Food Processing Plant

Key Capsule Checkweighers For Buyers To Evaluate In The Upcoming Year 2025

Tablet Sampling Machines Unveiled: The Definitive Guide For Laboratory Selection

Innovative Folder Gluer Features Driving Carton Line Efficiency In 2025