The Future of Food is AI What to Expect in 2026

By 2026, the ai and food industry will undergo a fundamental transformation. AI-driven predictive analytics and robotic automation are emerging realities, promising hyper-efficient operations and personalized experiences. This rapid adoption is reflected in significant market growth projections.

| Metric | Value |

|---|---|

| Market Size (2024) | USD 8.15 billion |

| Forecast (2033) | USD 28.72 billion |

| CAGR (2026-2033) | 15.1% |

Key AI Trends Redefining the Customer Experience

By 2026, artificial intelligence will fundamentally reshape how customers interact with food brands. AI is moving beyond the back office. It now directly enhances the dining experience through speed, personalization, and trust. These advancements create a more responsive and satisfying journey from the initial order to the final bite.

Predictive Analytics for Hyper-Efficient Service

Restaurants are leveraging predictive analytics to anticipate customer needs with remarkable accuracy. AI algorithms analyze historical sales data, weather patterns, local events, and even holidays. This analysis allows kitchens to forecast demand for specific menu items. Managers can optimize inventory levels, reducing both food waste and the risk of stockouts.

This technology also transforms front-of-house operations. AI predicts peak and slow hours, enabling managers to create smarter staffing schedules. Proper staffing ensures that service remains fast and efficient, even during unexpected rushes. Some restaurants have reported wait time reductions of up to 40% by using AI to anticipate demand. McDonald's, for instance, successfully used predictive AI in its drive-thrus. The system analyzed order data and timing, cutting average wait times by 30 seconds and demonstrating the power of forecasting.

Note: Predictive ordering continuously learns from new transactions. This process refines its accuracy over time, making operations progressively smoother and more efficient.

Robotic Automation in Kitchens and Delivery

Robotic automation is revolutionizing food preparation and delivery. In the kitchen, AI-powered robots perform repetitive tasks with precision and speed. These automated systems can handle everything from frying and grilling to chopping ingredients and assembling meals.

- Chipotle is testing an autonomous kitchen assistant to make and season its tortilla chips.

- White Castle and Wendy's have deployed robots for cooking burgers and fries, ensuring consistent quality and faster service.

- Companies like Miso Robotics develop assistants such as "Flippy" that integrate directly into existing kitchen workflows.

The final mile of the customer journey is also being automated. Autonomous delivery robots are becoming a common sight in urban areas and on college campuses.

| Company | Focus | Key Partners |

|---|---|---|

| Starship Technologies | Sidewalk delivery robots | Uber Eats, Grubhub |

| Nuro | Electric autonomous vehicles | Kroger, Domino's |

| Serve Robotics | Last-mile urban delivery | Uber Eats, 7-Eleven |

These robots offer a cost-effective and sustainable solution for getting food to customers quickly. They navigate sidewalks and streets using a combination of sensors, cameras, and machine learning.

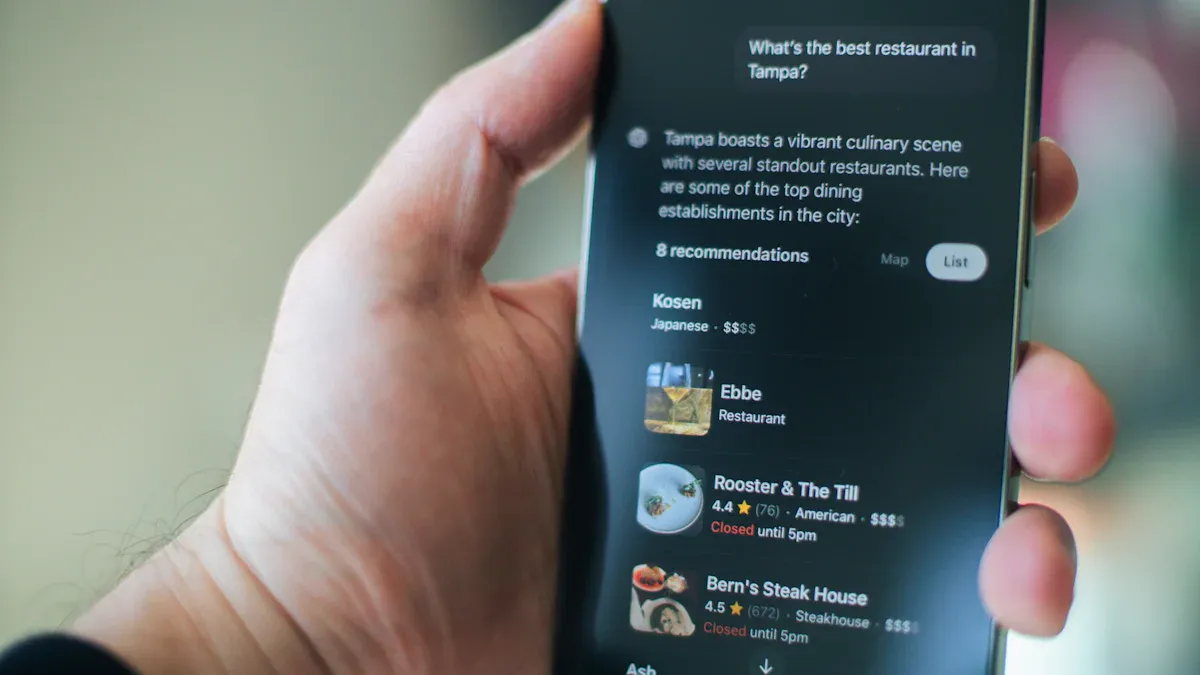

AI-Powered Personalization and Ordering

The ai and food industry is creating deeply personalized experiences for every customer. AI recommendation engines analyze purchase histories, dietary preferences, and contextual data like the time of day. This allows digital menus and apps to dynamically highlight items a specific customer is likely to enjoy. The system can even suggest a cold drink on a hot day or a comforting meal during cold weather.

Voice assistants and AI chatbots are also streamlining the ordering process. These tools allow customers to place orders conversationally, reducing friction and improving accuracy.

- Domino's "Dom" assistant processes voice orders through its app and smart home devices.

- Wendy's "FreshAI" voice bot takes drive-thru orders and even suggests intelligent upsells like combo meals.

- Starbucks uses its "My Starbucks Barista" to verify orders, process payments, and offer customized suggestions based on past purchases.

These systems make ordering faster and more intuitive. They also free up employees to focus on higher-value tasks that enhance the customer experience.

Enhanced Food Safety and Supply Chain Trust

AI is building a new foundation of trust between consumers and food producers. AI-driven systems analyze data from sensors embedded throughout the supply chain. These sensors monitor variables like temperature, humidity, and oxygen levels. Machine learning algorithms then identify patterns or anomalies that could indicate spoilage or contamination, triggering immediate alerts. This shifts food safety from a reactive to a proactive model.

The integration of AI with blockchain technology creates an even more powerful system for transparency.

- Immutable Records: Blockchain creates a permanent, unalterable log of a food product's journey from farm to table.

- Instant Traceability: In the event of a contamination issue, officials can instantly trace a product back to its source, enabling targeted recalls that minimize waste and protect public health.

- Consumer Confidence: Customers can scan a QR code to see verifiable information about a product's origin, handling, and ethical sourcing.

This combination of AI and blockchain provides unprecedented visibility into the food supply chain. It empowers consumers with reliable information and helps companies comply with complex safety regulations.

How AI is Reshaping Core Food Industry Operations

Beyond the customer-facing experience, artificial intelligence is revolutionizing the foundational operations of the food sector. By 2026, AI will be the engine driving product innovation, manufacturing efficiency, and supply chain logistics. This integration allows companies to operate with greater speed, precision, and intelligence from concept to consumer.

AI-Led Product Development and Innovation

Artificial intelligence is dramatically accelerating how new food products are conceived and brought to market. Companies now use AI to analyze vast datasets of consumer preferences, social media trends, and sales figures. This process uncovers emerging flavor profiles and dietary demands faster than traditional market research ever could.

AI tools allow companies to detect trends in real-time, model consumer scenarios, and rapidly test product concepts. Major brands like Danone and Unilever use AI to understand consumer needs and simulate millions of recipe combinations in seconds. This "in-silico" testing refines products digitally before any physical ingredients are mixed, significantly reducing development time and costs.

This data-driven approach has already produced several innovative products that might not exist otherwise. AI platforms are discovering novel ingredient combinations to create unique tastes and textures.

- NotCo used its AI platform, Giuseppe, to analyze the molecular structure of animal products. It found that pineapple and cabbage juice could replicate the creaminess of milk, leading to its NotMilk® plant-based beverage.

- Zhong Xue Gao in China launched an entire ice cream line designed by AI. The system developed the flavors, packaging concepts, and even promotional materials.

- Hell Energy in Hungary fed an AI system its sales data, ingredient lists, and consumer feedback. The AI then created a completely new energy drink flavor, "Tutti Frutti & Berry Blast."

Smart Manufacturing and Quality Control

In food manufacturing, AI-powered systems are setting new standards for quality and efficiency. Smart factories use computer vision and machine learning to monitor production lines with superhuman accuracy. AI-equipped cameras inspect products for defects, inconsistencies, and foreign contaminants that the human eye might miss. These systems do more than just identify problems; they learn and adapt. Deep learning models can classify subtle defects, like the color variation in a baked loaf of bread, and predict quality issues before they escalate.

This technology delivers tangible improvements across the factory floor. Manufacturers report double-digit gains in output and a significant reduction in product giveaway from overfilling. The benefits of AI-driven quality control are clear:

- Enhanced Accuracy: AI algorithms detect minor blemishes, incorrect labels, and contaminants like plastic or metal fragments, ensuring consistent product quality.

- Reduced Waste: By identifying defects early in the process, manufacturers can correct issues in real-time, minimizing the amount of discarded product.

- Optimized Performance: AI monitors equipment and predicts maintenance needs, reducing unexpected downtime and keeping production lines running smoothly.

- Regulatory Compliance: Automated systems provide detailed records and traceability, helping companies meet strict food safety regulations with ease.

Automated Inventory and Demand Forecasting

Managing inventory is one of the biggest challenges in the ai and food industry, especially with perishable goods. AI is solving this problem with highly accurate demand forecasting and automated inventory management. Modern AI platforms, like those from Afresh and OrderGrid, use sophisticated neural networks to predict future sales. These systems analyze historical data, weather forecasts, local events, and real-time transactions to create precise demand models for every single item in a store.

Instead of just predicting a single sales number, advanced AI models predict a distribution of likely demand. This approach helps grocers and restaurants make smarter ordering decisions for complex items like fresh produce, which have many variables affecting their shelf life. Automated systems then use these forecasts to manage stock levels with unparalleled precision. This leads to smarter ordering, more accurate prep lists in kitchens, and a dramatic reduction in both food waste and costly stockouts. Key functions include:

- Real-time Tracking: Systems monitor stock levels instantly, providing an accurate count of every ingredient.

- Automated Ordering: AI analyzes usage patterns and automatically generates purchase orders, preventing overstocking and ensuring key items are always available.

- Expiration Alerts: The system tracks shelf life and sends alerts for items nearing their expiration date, facilitating a "First-In, First-Out" (FIFO) usage model to reduce spoilage.

- Waste Reduction: By optimizing inventory, some businesses have cut food waste by up to 50%, directly improving profitability and sustainability.

The Impact of AI and Food Industry Leaders

Theory is becoming practice as leaders in the ai and food industry deploy intelligent systems to gain a competitive edge. These case studies demonstrate how AI is already delivering measurable results in efficiency, consistency, and personalization.

Case Study: Domino's Predictive Ordering

Domino's uses a sophisticated predictive ordering system to anticipate customer demand. The company leverages a powerful stack of AI technologies to train its models and deliver real-time insights.

| AI Technology | Application in Predictive Ordering |

|---|---|

| AI Algorithms | Analyzes online behavior to start pizza prep early. |

| NVIDIA GPUs | Trains complex AI models with significant speed. |

| NVIDIA RAPIDS | Improves performance in building datasets for AI. |

This proactive approach has yielded remarkable outcomes. The system enables Domino's to prepare for orders before they are even placed, leading to significant operational gains.

- Product quality improved by 14-15% in stores using the tool.

- Delivery time accuracy increased from 75% to an impressive 95%.

- Overall delivery times were cut, allowing for more efficient driver trips.

Case Study: Chipotle's Robotic Kitchens

Chipotle is integrating robotic automation directly into its kitchens to handle repetitive tasks. Its "Chippy" robot, an autonomous kitchen assistant, focuses on perfecting one of its most popular items. The robot performs several key functions:

- Cooks tortilla chips using corn masa flour, water, and oil.

- Seasons the chips with salt and fresh lime juice.

- Replicates subtle variations to mimic a human touch.

Beyond chips, Chipotle's "Autocado" prototype demonstrates the impact on labor. This system cuts guacamole preparation time in half. This frees employees to focus on customer service while ensuring product consistency and enhancing food safety.

Case Study: Sweetgreen's AI-Driven Personalization

Sweetgreen leverages AI to create a deeply personalized customer journey. Its system analyzes a user's order history, stated dietary goals, and behavioral patterns to offer tailored recommendations. Machine learning algorithms learn from each interaction, predicting future orders and suggesting new items that align with individual preferences. This data-driven approach allows Sweetgreen to move beyond generic marketing and connect with customers on a one-to-one basis, making healthy eating more intuitive and accessible.

The Tangible Benefits of an AI-Driven Food Future

The integration of artificial intelligence delivers clear advantages for both companies and their customers. Businesses gain a powerful toolkit for boosting profitability and sustainability. Consumers receive a more convenient and trustworthy food experience. These benefits are not abstract concepts; they are measurable outcomes transforming the industry.

For Businesses: Profitability and Sustainability

For businesses, AI directly translates to improved financial performance and stronger environmental stewardship. AI-powered systems optimize operations, turning efficiency into profit. Predictive analytics and automated inventory management drastically reduce overstocking and spoilage. This optimization has a significant impact on the bottom line.

- AI-driven demand forecasting helps retailers cut overstocking by up to 30%.

- Smart energy monitoring in processing plants can lower energy consumption by 15%.

- Automated waste tracking allows restaurant chains to reduce food waste by 20% or more.

These advancements help companies operate more sustainably. Reduced waste and optimized energy use lower the environmental footprint of the ai and food industry. This creates a dual benefit of cost savings and enhanced brand reputation.

For Consumers: Convenience and Confidence

Consumers benefit from an AI-driven food future through enhanced convenience and greater confidence in their food. AI streamlines the entire customer journey, from personalized ordering to faster delivery. The technology also builds a new foundation of trust. AI-powered food safety management moves the industry from a reactive to a proactive model. It detects potential issues early, ensuring products are safe for consumption.

This transparency empowers consumers. They can access verifiable information about a product's origin and journey. This capability prevents food fraud and enables swift, targeted responses to recalls. Ultimately, AI provides the assurance and speed that modern consumers demand, making every meal more reliable.

By 2026, the food industry will operate as an intelligent, automated ecosystem. Predictive operations, robotic assistance, and data-driven personalization are actively shaping this new era. This evolution promises a smarter food future, though it demands significant infrastructure investment and careful management of ethical concerns like worker job displacement.

FAQ

How will AI affect jobs in the food industry?

AI handles repetitive tasks like frying or data entry. This shifts employees toward roles focused on customer service and complex problem-solving, redefining jobs rather than simply eliminating them.

Is AI-driven food technology expensive for businesses?

Initial investment can be high. However, AI reduces long-term costs through less waste and greater efficiency. This provides a strong return on investment for many companies.

How does AI use personal data for ordering?

AI analyzes past orders and stated preferences. It uses this data to suggest relevant items, creating a personalized menu experience without sharing sensitive personal information with third parties.

See Also

Essential Industrial Checkweighers For Optimal Food Plant Operations

Leading Capsule Checkweighers For Savvy Buyers To Consider In 2025

Innovative Folder Gluer Features Revolutionizing Carton Lines In 2025

Unveiling Designer Creativity Through The Intricate World Of Computer Chips

Comparing Top Ampoule Filling Production Line Manufacturers In A Showdown