How to Achieve Perfect Granules with a Rapid Mixer Granulator

Manufacturers achieve perfect granules through precise control over three critical areas. The pharmaceutical industry, a primary user of the Rapid Mixer Granulator, relies on this precision for consistent product quality and uniform active ingredient distribution. Mastery involves managing raw material properties, optimizing operational parameters, and perfecting binder addition methods. This guide provides the exact steps for achieving consistent, high-quality results in each of these domains, ensuring superior granule characteristics for modern manufacturing.

Master Raw Material Inputs for Granulation Consistency

Achieving perfect granules begins long before the granulation process itself. The physical properties of the Active Pharmaceutical Ingredients (APIs) and excipients are the foundation of a successful batch. Operators who standardize these inputs gain precise control over the final product, ensuring batch-to-batch uniformity and quality.

Control Particle Size of APIs and Excipients

Consistent particle size is a non-negotiable prerequisite for uniform granulation. A wide or poorly controlled particle size distribution (PSD) in the raw powder blend directly leads to inconsistencies in the final granules and subsequent processing steps. These issues often manifest as:

- Granule Segregation: Differences in particle size and density cause materials to separate during handling, leading to non-uniform API distribution.

- Inconsistent Die Filling: Poorly flowing granules with a wide PSD result in underfilled or overfilled dies, causing significant tablet weight variation.

- Fines and Dust Accumulation: Excess fine particles can clog equipment or compact prematurely, disrupting the manufacturing process.

The primary particle size also dictates the final granule characteristics. For instance, using larger primary particles generally results in larger, less porous wet granules. Operators must therefore establish a target PSD for all incoming materials to ensure predictable and repeatable granulation performance.

Manage Material Moisture Content

The initial moisture content of raw materials is another critical variable that profoundly impacts granule quality. Even slight variations can alter the granulation process, affecting granule hardness and friability.

Pro Tip: Excessive initial moisture, particularly levels above 4.9%, often causes over-granulation. This leads to larger, less uniform granule structures. Consequently, the tabletability of these granules can decrease sharply, sometimes by as much as 50%, as moisture levels rise.

This reduction in performance is directly linked to the oversized and structurally weak granules formed from an overly moist powder bed. To prevent this, manufacturers must define strict moisture content specifications for all APIs and excipients. Verifying the moisture of every material batch before it enters the HLSG Series Rapid Mixer Granulator is a crucial quality control step for achieving consistent results.

Optimize Critical Parameters of Your Rapid Mixer Granulator

Once raw materials are standardized, operators must master the machine's operational settings. The precise control offered by a modern Rapid Mixer Granulator allows for the fine-tuning of granule properties. Optimizing impeller and chopper parameters, along with accurately identifying the granulation end-point, is essential for achieving batch-to-batch consistency.

Set the Right Impeller Speed and Time

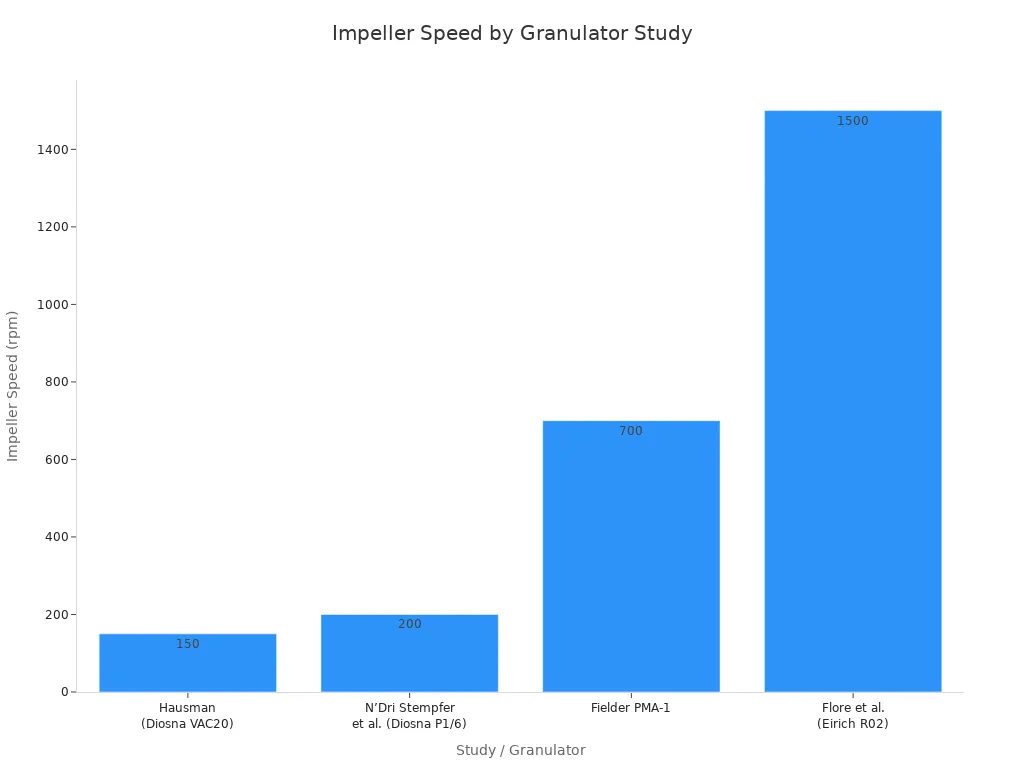

The impeller is the primary driver of granulation, providing the mechanical force needed to mix powders and distribute the binder liquid. Its speed directly influences granule density. Experimental studies show that increasing impeller speed often produces denser granules. This densification occurs as the increased force compacts the wet powder mass more effectively. However, the ideal speed is highly dependent on the specific formulation and granulator model.

As shown above, impeller speeds can range from 150 RPM in some low-shear processes to over 1500 RPM in high-shear applications. Operators must determine the optimal speed and mixing time for their specific product to achieve the target granule characteristics.

Calibrate Chopper Speed and Duration

The chopper complements the impeller by breaking down large, wet lumps into smaller fragments. This high-speed tool, often rotating between 1440 and 2880 RPM, cuts through agglomerates to ensure uniform moisture distribution and prevent oversized granules. While some studies show that chopper speed has a minimal effect on final granule size, others find it helps narrow the size distribution. Its primary function remains breaking up lumps, which is especially critical for formulations that tend to form large clumps. The right chopper speed prevents process failures and ensures the impeller can uniformly mix the material.

Determine the Granulation End-Point

Identifying the precise moment to stop the granulation process is perhaps the most critical step. Stopping too early results in fine, under-granulated powder, while stopping too late causes oversized, overly dense granules.

End-Point Detection Method: A common and effective method is monitoring the power consumption of the impeller motor. As granules form and grow, the load on the impeller increases, causing a rise in the motor's amperage. A stable plateau in the power consumption curve typically indicates that the desired granule consistency has been reached and the process is complete.

For even greater precision, manufacturers increasingly use Process Analytical Technology (PAT). Tools like Focused Beam Reflectance Measurement (FBRM) provide real-time particle size analysis directly within the Rapid Mixer Granulator, offering unparalleled control and ensuring the perfect end-point is achieved every time.

Perfect Your Binder Addition Technique

The final piece of the granulation puzzle is the binder liquid itself. How it is prepared and introduced into the powder bed dramatically influences final granule quality. Mastering the binder addition technique ensures strong, uniform granules with the desired release characteristics.

Optimize Binder Liquid Quantity and Concentration

The amount of binder liquid is a critical factor. A significant risk in wet granulation is the potential for either over-wetting or under-wetting the material. This imbalance leads directly to inconsistencies in granule quality. Operators must find the precise liquid saturation point for their specific formulation.

The binder's concentration is equally important. Common binders fall into several categories:

- Matrix Type: Coal tar pitch, clay, dry starch

- Film Type: Water, starch, lignosulfonates, molasses

- Chemical Binders: Ca(OH)₂ + Molasses

Higher binder concentrations create stronger bonds between particles. This increases granule mechanical strength but can also slow drug release by delaying the penetration of dissolution media. Studies on high-dose drugs like metformin have explored various binder concentrations, from 2% to 10%, to achieve optimal tabletability. The relationship is clear:

| Binder Concentration | Granule Strength | Dissolution Rate |

|---|---|---|

| Higher | Increased | Decreased |

| Lower | Decreased | Increased |

Control Binder Addition Rate and Method

The speed and method of binder addition control moisture distribution within the powder. A slow, controlled addition rate is essential for uniform wetting. Modern equipment like the HLSG Series Rapid Mixer Granulator provides this precise control, ensuring even application and minimizing variations in granule size.

Operators can choose between two primary addition methods: pouring or spraying. Each method produces different granule characteristics. Spraying generally creates more fines but can improve tablet tensile strength, while pouring results in less friable granules.

Pro Tip: The choice between spraying and pouring depends on the desired final product attributes. A spray nozzle offers better liquid distribution, while a steady pour can be effective for certain formulations.

| Attribute | Spray Addition | Pouring Addition |

|---|---|---|

| Fines | Increased | Decreased |

| Granule Friability | Increased | Decreased |

| Tablet Tensile Strength | Increased | Decreased |

| Tablet Disintegration Time | Increased | Decreased |

By carefully selecting the binder, optimizing its concentration, and controlling its addition, manufacturers gain ultimate command over the granulation process.

Achieving consistent, high-quality granules with a Rapid Mixer Granulator is a systematic process. Manufacturers who master these variables ensure their R&D success translates reliably to production scale. Following this checklist helps meet regulatory expectations and delivers predictable performance.

- Material Properties: Standardize particle size and control moisture for a consistent foundation.

- RMG Parameters: Optimize impeller and chopper settings on the Rapid Mixer Granulator and accurately determine the granulation end-point.

- Binder Addition: Perfect the binder quantity, concentration, and addition rate for ideal granule strength.

Systematic control is the key to unlocking the full potential of your Rapid Mixer Granulator.

FAQ

What is the primary advantage of the HLSG Series?

The HLSG Series Rapid Mixer Granulator significantly boosts efficiency. It completes all granulation steps within one sealed container. This streamlined process is 4-5 times faster than conventional methods, accelerating production cycles and ensuring full compliance with GMP standards.

How does this granulator improve granule quality?

The HLSG Series produces nearly spherical granules with excellent flow properties. This uniformity enhances final product quality. Its innovative design also reduces binder usage by up to 25% and shortens drying times, leading to significant cost savings and improved process control.

What is the typical processing time for a batch?

A typical batch completes dry mixing in approximately 2 minutes. The granulation phase follows, lasting only 1-4 minutes. This rapid cycle time represents a major efficiency gain over traditional granulation techniques, allowing for higher throughput in manufacturing operations. ⏱️

How does an operator know when granulation is complete?

Operators determine the end-point by monitoring the impeller motor's power consumption. A stable plateau in amperage indicates that granules have formed and the process is complete. This method provides a reliable, data-driven signal to stop the granulation process at the optimal time.

See Also

Comparing Top Ampoule Filling Production Line Manufacturers: A Comprehensive Review

Unveiling Five Optimal Applications for Single-Stage Rotary Vane Vacuum Pump Sets

Boosting Pharmaceutical Efficiency: The Impact of Modern Capsule Decapsulation Machines

Ten Clever Methods to Incorporate Bovine Gelatin Powder into Culinary Creations

Capsule Sorters: Essential Tools for Effective Defect Removal and Quality Control