How to Guarantee Perfect Dosage with Automated Weighing

An Automatic Checkweigher guarantees perfect dosage by weighing 100% of products on the production line. The system instantly identifies and rejects any item outside precise weight specifications. Using an Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills ensures every unit is perfect, preventing costly errors.

The Financial Impact of Inaccuracy

- Unsellable goods cost the consumer sector $15 billion annually.

- A single product delay from mislabeling cost one company over €517 million.

Key Takeaways

- Automated checkweighers weigh every product on the line. This ensures correct dosage and prevents errors.

- These machines use high-speed weighing and precise settings. They remove wrong-weight items quickly.

- Using an automated checkweigher saves money and keeps customers safe. It helps meet strict rules and improves production.

How Automated Checkweighers Ensure Perfect Dosage

An automated checkweigher is a cornerstone of modern quality control. It provides a systematic, error-free method for ensuring every product meets exact weight specifications. This technology operates through a three-step process: high-speed weighing, precise tolerance setting, and automated rejection. Each step works together to guarantee perfect dosage and protect both the consumer and the manufacturer.

High-Speed, In-Motion Weighing

Modern production lines operate at incredible speeds. A checkweigher must keep pace without creating a bottleneck. In-motion weighing technology allows the system to weigh every single product as it moves along the conveyor belt. There is no need to stop the line. This 100% inspection is critical for industries like pharmaceuticals, where dosage accuracy is non-negotiable.

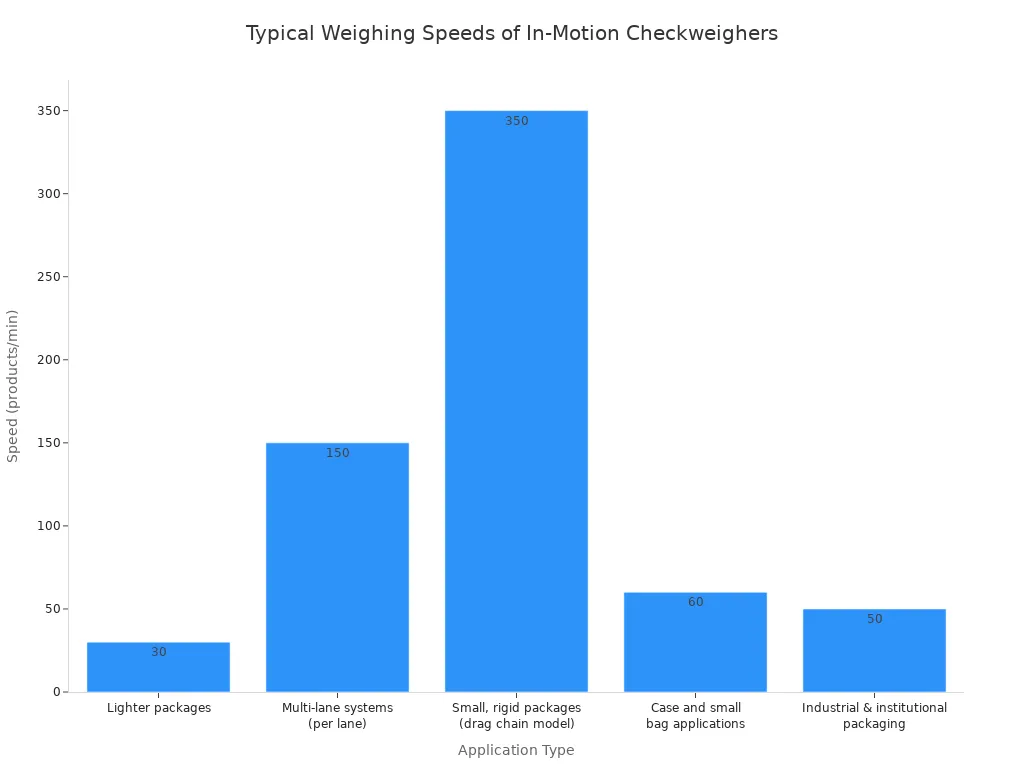

The system uses advanced sensors and processing algorithms to capture precise weight data in milliseconds. For example, the Online Checkweigher for Tablets Capsules Pills utilizes high-precision electromagnetic balance sensors and a DSP high-speed signal processing system. This combination delivers accurate, real-time results even on the fastest production lines. Weighing speeds vary based on the product and system configuration, but modern checkweighers are built for efficiency.

Note: The ability to weigh every item without slowing production is a key advantage of automated systems. This ensures comprehensive quality control that manual spot-checking can never achieve.

Setting Precise Weight Tolerances

After weighing a product, the checkweigher compares the result to a pre-defined acceptable weight range. Operators set this range, known as the weight tolerance, directly in the system's software. This involves defining a target weight and the acceptable upper and lower limits. Any product falling outside these precise boundaries is flagged as non-conforming.

For pharmaceutical products like tablets and capsules, these tolerances are extremely tight. An advanced system can manage tolerances with incredible precision. The Online Checkweigher for Tablets Capsules Pills, for instance, offers a display scale of 0.1mg and a sorting accuracy as fine as ±0.5mg. This level of control is essential for:

- Preventing underfills: Ensures patients receive the correct, effective dosage.

- Eliminating overfills: Avoids product giveaway and saves valuable active pharmaceutical ingredients (APIs).

- Meeting regulatory standards: Guarantees compliance with strict industry regulations like 21CFR part11.

The system stores these settings in product formulas, allowing for quick and easy changeovers between different products on the same production line.

Automated Rejection Mechanisms

The final step in the process is handling non-conforming products. When a checkweigher detects an over- or underweight item, it activates an automated rejection mechanism. This device physically removes the flagged product from the production line without interrupting the flow of compliant products. This immediate action prevents defective items from ever reaching the packaging stage or the consumer.

Different rejection systems are designed for various product types, weights, and line speeds. Common mechanisms include:

- Air Jet: Uses a sharp blast of compressed air to blow lightweight items (under 1 lb) off the conveyor. It is simple, fast, and effective for products like individual capsules or small blister packs.

- Pusher: Employs a pneumatic arm with a plate to gently push heavier items (up to 8 lbs) off the line. This method is ideal for boxes or bottles.

- Drop Belt: A section of the conveyor belt quickly drops down, allowing the non-conforming item to fall into a rejection bin below. This is useful for fragile or sticky products that need gentle handling.

- Diverter Arm: A swinging gate guides the product onto a separate conveyor or into a collection area. This is perfect for items that must remain upright, such as uncapped bottles.

These automated systems ensure that rejected products are handled swiftly and correctly. This maintains high productivity, enhances quality control, and reduces waste by isolating faulty items for rework or disposal.

Achieving Accuracy 0.1mg with an Online Checkweigher for Tablets Capsules Pills

In the pharmaceutical industry, precision is not a goal; it is a requirement. Achieving an accuracy level of 0.1mg is critical for ensuring dosage safety and efficacy. An Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills is a precision weighing solution built for this exact purpose. It automatically screens and separates every single product, guaranteeing that each unit meets strict weight standards. Advanced models deliver this high level of precision with a display scale of 0.1mg.

| Type | Display scale |

|---|---|

| SG-JN10/SG-JN20/SG-JN30 | 0.1mg |

This technology provides accurate, real-time results, which enhances operational efficiency and protects product integrity.

Eliminate Product Giveaway and Underfill

Every pharmaceutical manufacturer faces two costly problems: product giveaway and underfill.

- Product Giveaway (Overfill): This occurs when a package contains more product than stated. While it may seem harmless, giving away valuable active pharmaceutical ingredients (APIs) directly erodes profits. Reducing giveaway by just a small amount per item can lead to thousands of dollars in annual savings. One manufacturer saw a 30% reduction in product giveaway within six months of implementing checkweighers.

- Underfill: This happens when a product contains less than the required dose. Underfills create serious risks. Patients may not receive a therapeutic dose, rendering the medication ineffective. This also exposes the company to legal penalties and mandatory recalls.

Manual spot-checking, which might inspect only 0.25% of a production run, cannot catch these errors consistently. An Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills inspects 100% of products. It identifies and removes any pill or capsule that is even slightly over or under the target weight, protecting both profits and patients.

Ensure Pharmaceutical Regulatory Compliance

Pharmaceutical manufacturing operates under strict government oversight. Regulations like the FDA's 21 CFR Part 11 mandate the integrity of electronic records and signatures. An Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills is designed to help companies meet these stringent requirements. The system creates automated audit trails that simplify compliance and provide proof of quality control.

These systems support compliance through several key features:

| Feature | How it Supports Audit Trails for Regulatory Compliance |

|---|---|

| User Access Control | Records all significant user actions, ensuring every change is tracked and accountable. |

| Automated Data Recording | Prevents manual data entry errors and stores information securely for easy retrieval during audits. |

| Comprehensive Audit Trails | Captures instrument ID, time stamps, and calibration history for complete traceability. |

| Electronic Signatures | Secures data authenticity and traces any changes back to a specific, authorized user. |

By automatically logging data for every unit, an Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills provides the documentation needed to pass audits. This technology helps manufacturers adhere to global weighing regulations, avoiding fines and preventing products from being removed from the market.

Protect Brand Integrity and Patient Trust

A single dosage error can have devastating consequences. In 2022, a recall of over 100,000 units of pediatric acetaminophen occurred due to dosage inconsistencies. In another case, over 2 million insulin pens were recalled because of a malfunction that caused a 3% overdose. These events, while not explicitly linked to a lack of checkweighers, highlight the critical danger of incorrect dosage. Such incidents can lead to patient harm and severely damage a company's reputation.

Trust is built on consistency. Patients and healthcare providers must trust that the strength on the label matches the dose in the product.

An Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills acts as a final safety check. It ensures that every tablet and capsule leaving the facility is precisely dosed. This commitment to quality control accomplishes several goals:

- Minimizes Product Recalls: It catches weight anomalies early, preventing defective products from ever reaching the market.

- Ensures a Consistent Experience: Patients receive a safe and effective product every time.

- Builds Reliable Quality: Investing in quality control measures like an Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills demonstrates a brand's commitment to safety, fostering deep consumer trust.

Optimize Filling with Feedback Control

Modern checkweighers do more than just reject bad products. They can actively improve the entire production process. Advanced systems integrate with upstream filling equipment to create a feedback control loop. This technology transforms quality control from a reactive to a proactive process.

Here is how it works:

- The checkweigher weighs each product in real-time.

- It analyzes weight data to detect trends, such as a slight but consistent overfilling.

- The system sends an electronic signal back to the filling machine.

- The filler automatically adjusts its volume to correct the trend immediately.

This closed-loop communication happens instantly without stopping the line or requiring manual intervention. The results are significant. One company that implemented automatic filler feedback saw dramatic improvements.

| Metric | Before Checkweigher (Manual) | After Checkweigher (Automatic Feedback) |

|---|---|---|

| Overfill Reduction | Frequent overfills | Reduced by 3 grams per unit |

| Yield Increase | N/A | Increased by 4% |

| Annual Material Usage | N/A | Dropped by 12 tons |

| Cost Savings (First Year) | N/A | Exceeded $40,000 |

By using an Accuracy 0.1mg Online Checkweigher for Tablets Capsules Pills with feedback control, manufacturers can reduce waste, increase yield, and run a more stable and efficient production line.

Online checkweighers are the definitive solution for perfect dosage. They provide 100% weight inspection and automated process control. The market for these systems is projected to grow 6.5% annually as more companies adopt this technology. Implementing an automated weighing solution eliminates dosage errors and protects profits on the production line.

FAQ

How does the checkweigher handle different product sizes?

The system uses a user-friendly mold design. Operators quickly change molds to weigh various capsules, tablets, and pills. This makes production flexible and efficient for different product runs.

Can this checkweigher integrate with an existing production line?

Yes. The checkweigher integrates seamlessly online with existing production equipment. It can also operate as a standalone unit, offering flexible installation options for any manufacturing setup.

What happens to the weight data the system collects?

The system offers rich data functions. It stores, queries, and prints production statistics. This supports regulatory compliance and provides detailed audit trails for quality assurance.

See Also

Understanding Pharmaceutical Checkweighers: Key Features for Quality Control

Tablet Sampling Machines: A Comprehensive Guide for Laboratory Selection

Top Capsule Checkweighers for Buyers to Evaluate in 2025

Essential Industrial Checkweighers: The Top Three for Food Plants

Automated Virus Sampling Tube Assembly Lines: A Smart Investment?