5 Key Uses for Inconel X-750 Round Bar

Inconel X-750 round bar is the material of choice for components that must perform flawlessly under extreme heat and mechanical stress. Its unique properties, including high-temperature strength and corrosion immunity, make it indispensable in demanding sectors like aerospace and nuclear power.

💡 Market Insight: The market for nickel-based superalloys reflects this importance. Projections show a Compound Annual Growth Rate (CAGR) of over 4.3%, driven by high demand in the aerospace and power generation industries.

This superalloy provides proven reliability where performance is non-negotiable.

Key Takeaways

- Inconel X-750 is a strong metal. It works well in very hot places. It does not break or bend easily under heat.

- This special metal is used in jet engines and rockets. It helps parts like turbine blades and nozzles work safely.

- Inconel X-750 makes strong bolts and springs. These parts hold things together in hot places like engines and furnaces.

- Nuclear power plants use Inconel X-750. It keeps reactor parts safe from heat and radiation.

- Tools for shaping hot metal use Inconel X-750. It helps these tools last longer and work better.

What Makes Inconel X-750 a High-Performance Superalloy?

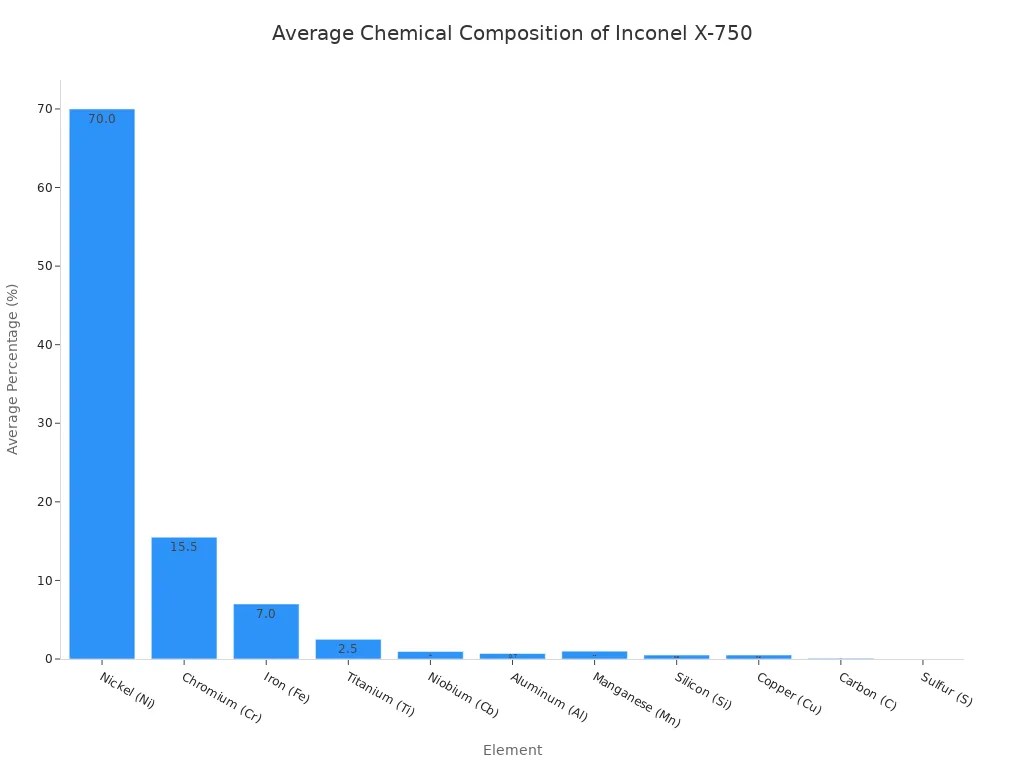

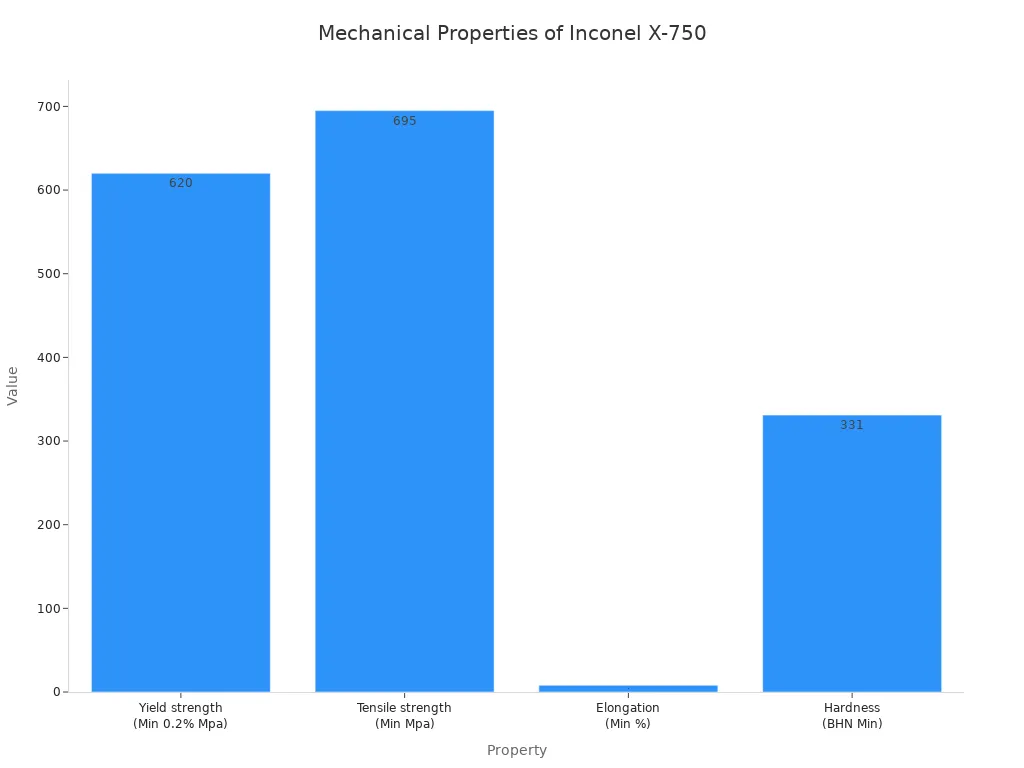

Inconel X-750 derives its elite status from a carefully balanced chemical composition. A high nickel content (over 70%) forms a stable, corrosion-resistant base. Key elements like chromium, titanium, and aluminum are added to create a precipitation-hardenable alloy with remarkable mechanical properties. This unique formulation makes it a go-to material for extreme service conditions.

Exceptional High-Temperature Strength

Many metals lose structural integrity as temperatures rise. Inconel X-750, however, maintains impressive strength at temperatures up to 1300°F (704°C). Its composition allows it to resist softening and deformation when exposed to intense heat. This characteristic is critical for components operating in combustion zones or high-temperature industrial processes where lesser alloys would fail.

Superior Creep and Stress-Rupture Resistance

In high-stress environments, materials can slowly deform over time in a process called creep. Inconel X-750 exhibits low creep rates even under significant loads at temperatures reaching 1500°F (816°C). This resistance to gradual deformation and sudden stress-rupture ensures long-term dimensional stability and reliability. Components made from Inconel X-750 round bar maintain their shape and function throughout extended service cycles.

Key Takeaway: The alloy's ability to resist creep ensures that critical parts like turbine blades and fasteners do not stretch or fail unexpectedly over their operational lifetime.

Excellent Corrosion and Oxidation Resistance

This superalloy provides robust defense against harsh chemical environments. Its high nickel and chromium content creates a passive, protective oxide layer that shields it from oxidation at temperatures up to 1800°F (982°C). Furthermore, it shows excellent resistance to chloride-ion stress-corrosion cracking, a common failure mode for many stainless steels in high-temperature chloride environments. This makes it a reliable choice for marine, chemical processing, and power generation applications.

The Role of Precipitation Hardening

The exceptional strength of Inconel X-750 is not inherent; it is unlocked through a precise metallurgical process known as precipitation hardening, or age hardening. This controlled heat treatment transforms the alloy's internal microstructure, dramatically enhancing its mechanical properties. The process fundamentally changes the material from a relatively soft, workable state into a superalloy capable of withstanding extreme stress and heat.

This transformation involves a carefully managed, multi-stage thermal cycle. The precise selection of variables during these steps is crucial for achieving the desired strength and longevity in critical parts. The general procedure includes:

- Solution Annealing: The alloy is first heated to a high temperature, typically just below its melting point. This step dissolves various elements into a uniform solid solution, creating a consistent internal structure.

- Quenching: Next, the material is rapidly cooled. This fast cooling traps the dissolved elements in a supersaturated state, preventing them from immediately reforming.

- Aging: Finally, the alloy is reheated to a lower, intermediate temperature and held there for an extended period. For some Inconel X-750 applications, this means holding the material at 1350°F (732°C) for approximately 16 hours before air cooling. During this aging phase, microscopic strengthening particles (precipitates) form throughout the alloy's metallic matrix.

⚙️ How It Works: These tiny, hard precipitates act as obstacles within the metal's crystal structure. They impede dislocation movement, which is the primary mechanism of plastic deformation. This resistance to internal movement is what gives the final Inconel X-750 round bar its immense hardness, high tensile strength, and superior creep resistance at elevated temperatures.

Use 1: Aerospace Gas Turbine Engines

The extreme environment inside a gas turbine engine demands materials that can withstand immense heat, pressure, and mechanical force. Inconel X-750 is a premier choice for manufacturing critical engine components, ensuring both performance and flight safety. Its properties allow engines to operate at higher efficiencies, pushing the boundaries of modern aviation.

Turbine Blades, Discs, and Wheels

Turbine blades, discs, and wheels are the heart of an engine's power section. These components rotate at tens of thousands of revolutions per minute while being blasted by hot gases. This creates enormous centrifugal forces and thermal stress. Inconel X-750 maintains excellent tensile strength at temperatures reaching 700°C (1292°F), preventing parts from stretching or deforming. Its resistance to creep ensures that blades and discs retain their precise aerodynamic shape for thousands of hours, maintaining engine efficiency and structural integrity.

Afterburner and Exhaust Components

The afterburner and exhaust sections of a military jet engine produce some of the most punishing temperatures, often exceeding 1,800°F (982°C). Inconel X-750 excels in these applications due to its superior oxidation resistance. It forms a stable, protective oxide layer that shields the underlying metal from rapid degradation. This allows components like flame holders, exhaust nozzles, and ducting to function reliably without failing from high-temperature corrosion, even during rapid thermal cycling.

Why It Outperforms Other Alloys in Engines

Many alloys, including high-grade stainless steels, lose their strength and begin to oxidize at the operating temperatures of a modern jet engine. Inconel X-750 provides a clear performance advantage. Its precipitation-hardened structure delivers the mechanical strength needed for rotating parts, while its chemical composition offers unmatched heat and corrosion resistance.

✈️ Performance Edge: The alloy's ability to handle repeated heating and cooling cycles (thermal fatigue) without cracking is a key reason engineers specify it for long-life engine parts.

The following table highlights the superior temperature capabilities that set it apart.

| Alloy | Maximum Operating Temperature |

|---|---|

| Inconel X-750 | Up to 980°C (1800°F) |

| Titanium | Up to 600°C (1112°F) |

| Stainless Steel (316) | Up to 870°C (1598°F) |

This thermal stability makes Inconel X-750 round bar the ideal starting stock for machining parts that guarantee reliability where failure is not an option.

Use 2: Rocket Propulsion Systems

Rocket propulsion systems operate at the frontiers of material science, creating conditions of extreme temperature, pressure, and vibration. Inconel X-750 provides the structural reliability needed to harness this immense power safely. Its unique properties make it a cornerstone material for building components that must perform without fail from launch to orbit.

Thrust Chamber and Nozzle Structures

The thrust chamber is where propellants combust, generating incredible heat and pressure. Inconel X-750 is an ideal material for these structures because it retains its strength under such thermal loads. Its use in the legendary F-1 rocket engine, which powered the Saturn V moon missions, is a testament to its capability. Engineers used the alloy for the F-1's thrust chamber tube bundle and reinforcing bands, relying on its strength to contain the engine's massive power.

High-Pressure Ducting and Manifolds

Rocket engines depend on a complex network of ducting and manifolds to transport cryogenic fuels and superheated gases. These components must resist embrittlement at low temperatures and maintain their integrity at high temperatures. Inconel X-750 excels in this role. It provides a leak-proof, durable solution for high-pressure fluid transfer. The F-1 engine's manifold system also utilized this superalloy, ensuring reliable propellant delivery under immense operational stress.

Maintaining Integrity During Combustion

A rocket engine's survival depends on its ability to withstand violent thermal cycling and vibration. Inconel X-750 delivers the necessary resilience, ensuring components do not warp, crack, or fail during flight.

🚀 Built for Extremes: The alloy's performance during combustion is rooted in several key characteristics:

- It maintains high strength and resists stress-corrosion cracking at the extreme temperatures found inside a rocket engine.

- A carefully balanced thermal expansion coefficient helps it maintain dimensional stability, preventing parts from deforming during rapid temperature changes.

- It exhibits excellent fatigue resistance, which is critical for enduring the intense vibrations and cyclic loads of a rocket launch.

Use 3: High-Temperature Fastening and Fixturing

In high-temperature environments, the components holding everything together are just as critical as the main structures. Inconel X-750 provides the essential strength and stability for fasteners, springs, and fixtures that must perform reliably when temperatures soar. Its unique properties prevent catastrophic failures caused by material degradation.

Bolts and Fasteners for Jet Engines

Bolts inside a jet engine must maintain their clamping force under extreme thermal and mechanical stress. Standard steel bolts would quickly lose strength, stretch, and fail. Inconel X-750 is specified for these critical applications because it retains exceptional tensile and creep-rupture properties at temperatures up to 1300°F (700°C). This ensures that engine casings, turbine assemblies, and other vital components remain securely fastened throughout thousands of flight hours. The alloy's strength guarantees that joints stay tight and secure.

Springs and Seals in Extreme Heat

Springs and seals used in high-temperature systems must resist "relaxation," a phenomenon where a material loses its elastic properties and fails to return to its original shape. Inconel X-750 exhibits excellent relaxation resistance, making it a premier material for springs in exhaust systems, pressure relief valves, and nuclear reactors.

🔥 Temperature Advantage: While high-grade stainless steel springs are limited to a maximum operating temperature of about 650°F (343°C), Inconel X-750 springs function reliably at temperatures up to 1300°F (700°C), providing a clear performance advantage where heat is a primary concern.

Heat-Treating and Furnace Fixtures

Industrial furnaces used for heat-treating metals operate at punishing temperatures for extended periods. The jigs and fixtures holding parts inside these furnaces must endure repeated thermal cycles without warping, scaling, or breaking. Machining these components from Inconel X-750 round bar provides a durable, long-lasting solution. Its key benefits in this role include:

- Resistance to deformation under heavy loads at high temperatures.

- Excellent oxidation resistance, which prevents scaling that could contaminate parts.

- High fatigue strength to withstand thousands of heating and cooling cycles.

Use 4: Nuclear Power Generation

Nuclear power plants generate energy under some of the most demanding conditions imaginable, requiring materials that offer absolute reliability. Inconel X-750 provides the necessary safety and performance for critical components operating within the reactor environment, where extreme heat, pressure, and radiation are constant factors.

Reactor Core and Control Rod Components

Reactor core structures and control rods are essential for managing nuclear reactions safely. These components must maintain their structural integrity without fail. Inconel X-750 is a trusted material for these applications because it meets the stringent requirements of the nuclear industry. Its performance is rooted in a combination of key properties:

- High Strength and Creep Resistance: It maintains its shape and strength under prolonged stress at temperatures up to 1500°F (815°C).

- Outstanding Corrosion Resistance: It withstands degradation from reactor coolants and other corrosive elements.

- Excellent Oxidation Resistance: It resists damage from high-temperature air and oxidizing agents.

- Fatigue Resistance: It endures the cyclic thermal and mechanical loads common in reactor operations.

Heat Exchanger and Boiler Tubing Supports

In a nuclear power plant, heat exchangers and steam generators transfer immense thermal energy. The tubing inside these systems is supported by grids and plates that must bear heavy loads at high temperatures. Inconel X-750 is an ideal choice for these support structures. It prevents the tubes from sagging or vibrating, which could lead to wear and catastrophic failure. The alloy’s ability to resist deformation and oxidation ensures these supports provide stable, long-term service.

Strength in High-Radiation Environments

⚛️ Engineered for Durability: Materials inside a reactor core are exposed to intense neutron irradiation, a condition that can degrade lesser alloys. The performance of Inconel X-750 in these high-flux environments is a subject of extensive study, with advanced techniques like High Resolution Transmission Electron Microscopy (HRTEM) used to analyze its microstructural stability.

This focus on research underscores the alloy's importance in nuclear applications. Engineers specify materials like Inconel X-750 Round Bar for core components because its robust, precipitation-hardened structure provides the strength needed to perform reliably throughout a long operational life, ensuring the safety and efficiency of the power plant.

Use 5: Industrial Hot-Working Tools

Industrial hot-working processes, such as extrusion and forming, require tools that can withstand extreme temperatures and immense mechanical forces. Inconel X-750 provides the durability needed for these demanding applications, ensuring tool longevity and consistent production quality. Its unique properties allow it to maintain its shape and hardness while in direct contact with heated metals and plastics.

Extrusion Dies for Metals and Plastics

Extrusion involves forcing material through a shaped die to create a continuous profile. This process generates intense friction and heat. Dies made from Inconel X-750 excel in this environment because the alloy resists wear and thermal fatigue. It maintains its critical dimensions even after thousands of cycles, ensuring the final extruded product meets precise specifications. This reliability reduces downtime and tooling replacement costs, making it a cost-effective choice for high-volume manufacturing of materials like aluminum and high-density polymers.

Forming Tools and Mandrels

Forming tools and mandrels shape hot metal through pressing, bending, or drawing. These tools must resist deformation under repeated high-pressure impacts at elevated temperatures. Inconel X-750 retains its high yield strength and hardness, preventing the tool from warping or losing its shape. This stability is crucial for producing accurately formed parts, from automotive components to industrial piping. The alloy’s resistance to oxidation also prevents scale from forming on the tool, which could otherwise transfer imperfections to the workpiece.

Resisting Deformation Under Pressure

The success of Inconel X-750 in hot-working applications comes down to its fundamental ability to resist deformation. Lesser materials would soften and deform, leading to tool failure and production defects. This superalloy delivers consistent performance.

🛠️ Built to Last: The alloy's strength is rooted in its precipitation-hardened microstructure. This internal structure provides exceptional resistance to:

- Plastic Deformation: It withstands high compressive forces without changing shape.

- Thermal Softening: It maintains hardness and strength at the high temperatures required for metal forming.

- Wear and Galling: It resists surface damage when in contact with other hot metals, extending tool life.

Performance Comparison: Inconel X-750 Round Bar vs. Other Alloys

Choosing the right material is critical for performance and safety. While many alloys exist, Inconel X-750 offers a distinct advantage in environments where others falter. Its performance profile justifies its selection for the most demanding applications.

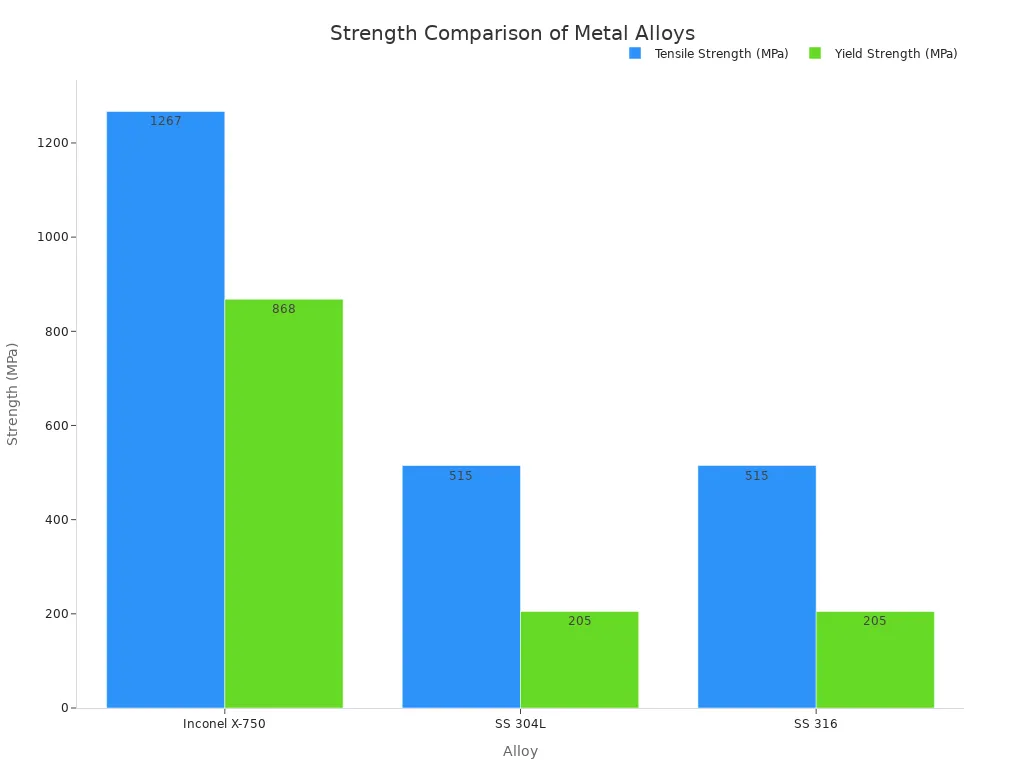

Against Stainless Steels

Common stainless steels like 304L and 316 are excellent for general corrosion resistance, but they cannot match Inconel X-750 in high-stress, high-temperature scenarios. The superalloy is specifically designed for the extreme conditions where stainless steel reaches its operational limits. The difference in mechanical strength is significant. Inconel X-750 provides more than double the tensile and yield strength of typical 300-series stainless steels, offering a much higher safety margin against mechanical failure.

This superior strength, combined with a useful service temperature extending to 700°C and beyond, makes it the clear choice for critical components like turbine parts and high-temperature fasteners.

Against Other Nickel Alloys

Within the nickel alloy family, Inconel X-750 holds a unique position. When compared to other popular grades like Inconel 718, the price difference is often not a major factor, as both are premium materials with similar costs, typically around $47 per kilogram. The choice between them depends on specific application needs. Inconel X-750 is often favored for its exceptional creep-rupture strength at very high temperatures and its excellent relaxation resistance, making it ideal for high-temperature springs and bolts.

Cost-Benefit Analysis for Critical Parts

The initial investment for an Inconel X-750 Round Bar is higher than for conventional metals. However, this upfront cost delivers substantial long-term value in critical applications.

📈 Return on Investment: The true value of Inconel X-750 is measured in reliability and reduced lifetime costs. Its use leads to:

- Extended Service Life: Components last longer, minimizing the frequency of replacements.

- Reduced Maintenance: Superior durability decreases the need for inspections and repairs, lowering downtime.

- Enhanced Safety: Its reliability prevents catastrophic failures in high-stakes aerospace and nuclear systems.

By minimizing unplanned maintenance and part replacement, the alloy provides significant operational and financial savings over the life of the component.

Inconel X-750 is the proven solution for applications where failure is not an option, from gas turbines to nuclear reactors. Its unmatched combination of high-temperature strength and durability ensures reliability in the most demanding environments.

🛡️ Key Performance Indicators for Reliability:

- High-Temperature Strength: Maintains integrity at temperatures up to 700°C (1300°F).

- Corrosion Resistance: A protective layer guards against harsh environmental conditions.

- Excellent Relaxation Resistance: Retains its shape and clamping force over time.

- Superior Creep Strength: Resists stretching under constant stress above 650°C (1200°F).

To secure your critical applications with Inconel X-750 Round Bar, consult with a material specialist to review your project requirements.

FAQ

Is Inconel X-750 difficult to machine?

Yes, machining Inconel X-750 presents challenges. The alloy work-hardens rapidly during cutting. Machinists must use powerful equipment, sharp tooling, and slow speeds to achieve precise results. Proper technique prevents tool wear and ensures component integrity.

Can you weld Inconel X-750?

Welders can successfully join Inconel X-750 using common methods like TIG and MIG welding. The material requires careful handling to prevent cracking. A post-weld heat treatment is often necessary to restore the alloy's optimal strength and corrosion resistance.

What is the main difference between Inconel X-750 and Inconel 718?

The primary difference lies in their high-temperature performance. Inconel X-750 offers superior creep-rupture strength at temperatures above 1300°F (700°C). Inconel 718, however, provides higher strength at lower to intermediate temperatures, making it suitable for different applications.

What forms does Inconel X-750 come in?

💡 Material Availability: While this article focuses on round bar, manufacturers produce Inconel X-750 in various forms. Common shapes include sheet, plate, strip, wire, and tubing. This versatility allows engineers to specify the alloy for a wide range of component designs.

See Also

Optimizing Steel Processing for Consistent Heat Exchanger Performance and Results

Essential Expert Guidance for Welding Pass Partition Plates: A 2025 Outlook

Assessing Molybdenum Plugs' Role in Seamless Steel Pipe Production: 2025 Insights

Key Facts: WT20 Thoriated Tungsten Electrodes Enhancing TIG Welding Quality

The 2025 Comprehensive Guide to Semi-Welded Plate Heat Exchangers in Industry