S32750 vs Other Stainless Steels A Simple Guide

Super Duplex S32750 provides significantly higher strength and superior corrosion resistance than both standard Duplex (2205) and Austenitic (316L) steels. This performance makes products like the S32750 Super Duplex Round Bar and the 2507 Super Duplex Round Bar top choices for harsh conditions. The 2507 alloy is the premier material for the most demanding environments. Industry adoption reflects its value, showing steady market growth.

| Metric | Value |

|---|---|

| Market Size 2024 | 3,360 USD Million |

| CAGR (2025-2035) | 4.5% |

While it represents a higher initial investment, its capabilities are essential for critical applications.

Key Takeaways

- S32750 is a strong stainless steel. It resists rust better than other steels like 2205 and 316L.

- S32750 is much stronger than 316L steel. This means engineers can use less material. This makes things lighter.

- S32750 works well in harsh places. These include seawater and oil and gas sites. Other steels might fail there.

- S32750 costs more at first. But it saves money over time. It lasts longer and needs fewer repairs.

S32750 vs. Standard Duplex (2205): The Upgrade

Engineers often view Super Duplex S32750 as a direct upgrade to the standard Duplex 2205 grade. While both materials share a dual-phase microstructure, S32750's enhanced chemical composition provides significant advantages in performance, particularly in corrosion resistance and mechanical strength. This makes it the superior choice for applications where 2205 reaches its operational limits.

Superior Corrosion Resistance

S32750 offers a substantial improvement in corrosion resistance over Duplex 2205. This enhanced performance stems from its higher content of chromium, molybdenum, and nitrogen. These elements work together to provide robust protection against uniform and localized corrosion. The difference becomes most apparent in environments with high chloride concentrations, where 2205 may be susceptible to failure.

Key Environments Where S32750 Excels:

- Aggressive Seawater: S32750 demonstrates superior resistance in natural seawater with chloride levels around 19,000 ppm. These conditions push Duplex 2205 beyond its ideal long-term service capabilities.

- Desalination Systems: The alloy is specified for highly corrosive desalination brine and high-pressure seawater injection systems. In contrast, Duplex 2205 is more commonly used on the less demanding freshwater side of these facilities.

Higher Strength and Lighter Designs

The mechanical strength of S32750 is another area where it significantly outperforms standard duplex steel. This higher strength is a direct result of its enriched alloying content. A comparison of their typical minimum yield strengths at room temperature highlights this clear advantage.

| Property | Typical Yield Strength |

|---|---|

| S32750 (Super Duplex) | ≥ 550 MPa (80,000 psi) |

| Duplex 2205 | ~450 MPa (65,000 psi) |

This notable increase in strength provides a critical engineering benefit. Designers can use the superior properties of the 2507 alloy to create components with reduced wall thickness without compromising safety or pressure ratings. This ability to use less material leads to lighter pipes, vessels, and structural elements. The resulting weight savings can reduce overall project costs by lowering fabrication, transportation, and installation expenses.

S32750 vs. Austenitic Steel (316L): A Different Class

Comparing Super Duplex S32750 to the widely used Austenitic 316L is like comparing a specialized tool to a general-purpose one. While 316L is a reliable workhorse for many applications, S32750 operates in a completely different performance category. Its advanced microstructure and chemical composition provide advantages that are critical for high-stress, corrosive environments where 316L would falter.

Double the Strength, Half the Weight

The most striking difference between S32750 and 316L is mechanical strength. S32750 possesses a minimum yield strength more than double that of 316L. This significant strength advantage allows engineers to design components with thinner walls and reduced cross-sections.

| Property | S32750 (Super Duplex) | 316L (Austenitic) |

|---|---|---|

| Minimum Yield Strength | 550 MPa | 205 MPa |

| Minimum Tensile Strength | 800 MPa | 515 MPa |

This capability directly translates to substantial weight savings. Lighter components reduce material costs, simplify transportation, and lower the structural support requirements for an entire project. The result is often a lower total installed cost, even with a higher initial material price.

Winning Against Stress Corrosion Cracking

Stress Corrosion Cracking (SCC) is a primary failure mode for austenitic steels like 316L, especially in environments containing chlorides at elevated temperatures. S32750’s duplex microstructure provides exceptional resistance to this threat.

Did You Know? 💡 Austenitic 316L steel becomes highly susceptible to SCC in chloride-rich environments once temperatures exceed approximately 60°C (140°F). In the same conditions, S32750 shows virtually no signs of cracking, ensuring long-term operational integrity.

Real-world incidents underscore the vulnerability of 316L. Failures in industrial settings often occur unexpectedly and within a few years of service.

- Compressor Plant Failure: In one documented case, 316L pipes in a compressor plant failed in less than four years. The failures occurred near welds where residual stress was high, in an environment with chloride content up to 900 ppm and operating temperatures around 52°C (126°F).

- Distillation Tower Incident: Structured packing made from 316L inside a phenol distillation tower failed due to chloride SCC, confirmed by microscopic examination.

These examples highlight why the robust SCC resistance of the 2507 alloy is essential for ensuring safety and reliability in critical process equipment.

Cost and Price Stability

While S32750 has a higher upfront cost per kilogram, its price is notably more stable than that of 316L. This stability is linked to the fluctuating price of nickel, a key alloying element.

| Steel Type | Nickel Content | Impact from Nickel Price Volatility |

|---|---|---|

| 316L Austenitic Steel | 8–14% | High |

| S32750 Duplex Steel | 6–8% | Moderate |

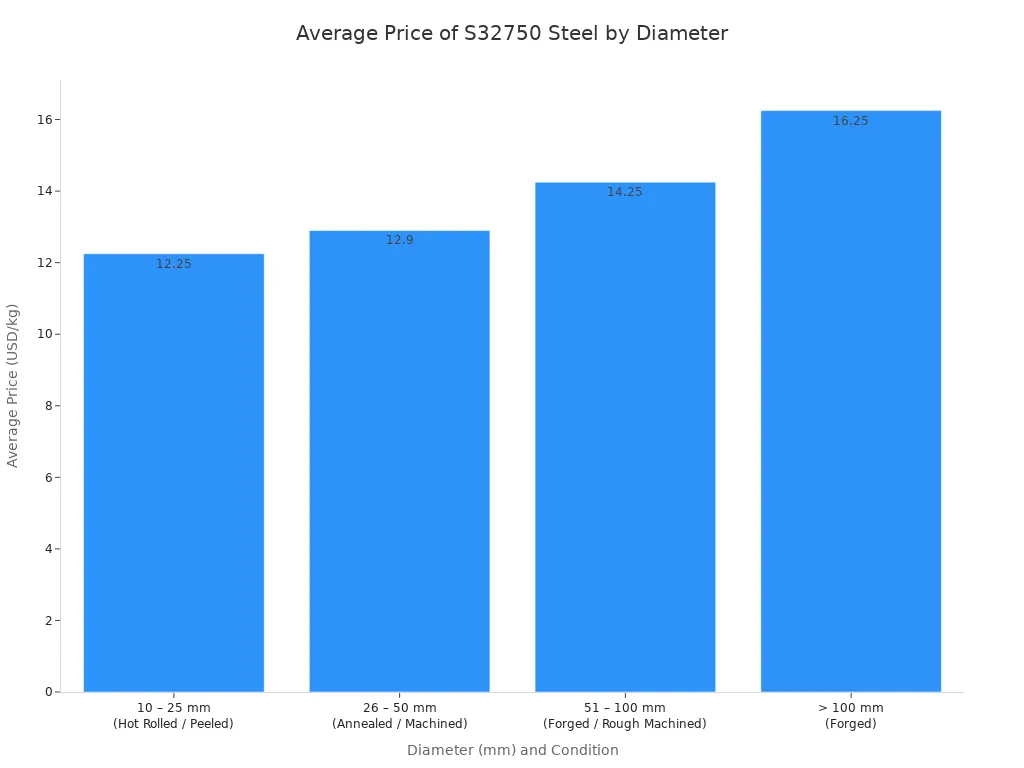

The higher nickel content in 316L makes its price highly sensitive to market swings. In contrast, S32750 contains less nickel, insulating its cost from this volatility and allowing for more predictable project budgeting. The initial price of S32750, typically ranging from $11.50 to $17.00 per kilogram for round bars, is influenced by factors like diameter, production method, and order quantity.

When considering the total lifecycle cost—factoring in reduced weight, enhanced durability, and lower risk of failure—the 2507 super duplex grade often emerges as the more economical choice for demanding applications.

Key Properties of Super Duplex 2507

The superior performance of Super Duplex S32750 stems from a carefully engineered combination of mechanical strength, corrosion resistance, and a unique internal structure. These three pillars work together to create a material capable of withstanding the world's most challenging industrial environments.

Exceptional Mechanical Strength

S32750 delivers impressive mechanical properties that far exceed those of common stainless steels. Its high nitrogen content contributes significantly to its strength, even in the annealed condition. Industry standards like ASTM A790 specify robust minimum values for this alloy, ensuring reliable performance under high-stress conditions.

- Tensile Strength: 800–1000 MPa (116,000–145,000 psi)

- Yield Strength: 550 MPa (80,000 psi) minimum

This exceptional strength allows for the design of thinner, lighter components without sacrificing structural integrity, making it ideal for pressure vessels and load-bearing applications.

Unmatched Corrosion Resistance

The alloy provides outstanding protection against various forms of corrosion. Its high levels of chromium, molybdenum, and nitrogen give it a superior ability to resist pitting, crevice corrosion, and general corrosion in acidic and chloride-rich media.

Performance in Sour Service In environments containing hydrogen sulfide (H2S), S32750 shows excellent performance. While laboratory tests indicate some susceptibility under severe conditions, the material has a successful track record in real-world applications at H2S pressures higher than lab data might suggest. Its low general corrosion rate reduces the hydrogen that can cause cracking.

The Austenitic-Ferritic Microstructure

The secret behind the alloy's balanced properties is its dual-phase microstructure. The 2507 grade is engineered to have a nearly equal mix of austenite and ferrite (approximately a 1:1 ratio). This optimal balance, achieved through precise solution treatment, prevents the formation of undesirable phases.

This structure combines the best attributes of both phases. The ferritic portion provides high strength and resistance to chloride stress corrosion cracking. The austenitic portion enhances toughness and acts as a barrier, effectively stopping cracks from propagating through the material. This synergistic relationship gives the alloy its signature combination of strength and durability.

Quick Comparison: S32750 vs. 2205 vs. 316L

A side-by-side comparison highlights the distinct performance tiers of these three popular stainless steel grades. Key metrics like strength and corrosion resistance reveal why S32750 is reserved for the most critical applications.

Comparing Yield Strength

Yield strength measures the stress a material can withstand before it permanently deforms. A higher yield strength allows for the design of stronger, lighter components. S32750 demonstrates a clear advantage over both 2205 and 316L.

| Grade | UNS No. | Minimum Yield Strength (MPa) |

|---|---|---|

| S32750 (Super Duplex) | S32750 | 550 |

| 2205 (Duplex) | S32205 | 450 |

| 316L (Austenitic) | S31603 | 170 |

The data shows that S32750 is over three times stronger than 316L, providing engineers with significant design flexibility.

Pitting Resistance Equivalent Number (PREN)

The PREN is a numerical value that predicts a steel's resistance to localized pitting corrosion, particularly in chloride-rich environments. A higher PREN indicates superior resistance.

PREN Hierarchy:

- S32750: PREN > 40 (Excellent for seawater)

- 2205: PREN ≈ 31-38 (Good for many marine uses)

- 316L: PREN ≈ 22-27 (Limited in warm chloride settings)

S32750's high PREN makes it exceptionally reliable in aggressive conditions where 316L would be highly susceptible to pitting.

Stress Corrosion Cracking (SCC) Resistance

SCC is a failure mechanism caused by the combined effect of tensile stress and a corrosive environment. The duplex microstructure of S32750 and 2205 provides outstanding protection against this threat, especially compared to austenitic 316L.

| Material | Resistance to SCC in Chloride Environments |

|---|---|

| S32750 (2507) | Excellent: Maintains performance in high-chloride media like brine and seawater. |

| 2205 | Very Good: Offers significantly better resistance than 316L. |

| 316L | Poor: Susceptible to failure in warm chloride environments. |

This superior SCC resistance makes the 2507 alloy an essential choice for ensuring long-term safety and operational integrity in critical process equipment.

General Cost Comparison

When evaluating stainless steels, cost extends beyond the initial purchase price. A comprehensive cost analysis considers the material's entire lifecycle. S32750 commands the highest initial price per kilogram, followed by Duplex 2205, with 316L being the most economical upfront option. However, this initial investment does not tell the whole story.

The superior strength of the 2507 alloy allows for designs with thinner walls and less material. This reduction in weight can significantly lower fabrication, shipping, and installation expenses. The material's exceptional durability also minimizes the need for costly maintenance, repairs, and downtime over the asset's lifespan. These factors contribute to a lower Total Cost of Ownership (TCO).

Understanding Total Cost of Ownership (TCO) 💰 TCO includes the initial purchase price plus all direct and indirect costs over the component's life. For S32750, a higher upfront cost is often offset by:

- Reduced Material Usage: Less steel is needed due to higher strength.

- Lower Fabrication Costs: Lighter components are easier to handle and weld.

- Minimal Maintenance: Superior corrosion resistance prevents costly repairs.

- Extended Service Life: The alloy's durability avoids premature replacement.

This table provides a general overview of the cost hierarchy, considering both initial price and long-term value.

| Steel Grade | Initial Cost | Total Lifecycle Cost (in Demanding Applications) |

|---|---|---|

| S32750 (Super Duplex) | High | Low to Moderate |

| 2205 (Duplex) | Moderate | Moderate |

| 316L (Austenitic) | Low | High |

For critical projects where failure is not an option, the long-term economic benefits of S32750 often present the most compelling value proposition. The initial investment ensures reliability and reduces future expenditures, making it a strategically sound financial decision.

When Should You Choose S32750?

Engineers select Super Duplex S32750 for applications where component failure could lead to significant safety risks or financial losses. Its combination of high strength and exceptional corrosion resistance makes it the premier choice for the most unforgiving operational settings. The material provides long-term reliability where standard stainless steels would quickly degrade.

Critical Oil and Gas Applications

The oil and gas industry relies on S32750 for its resilience in high-pressure, corrosive environments. The material's approval under the NACE MR0175/ISO 15156 standard confirms its suitability for service in H₂S-containing (sour) conditions. This makes it essential for ensuring the integrity of critical infrastructure. Common applications in offshore and onshore systems include:

- Subsea manifolds and components

- Flowlines

- Piping and heat exchangers

The alloy's strength and corrosion resistance ensure operational safety and longevity in these demanding roles.

Harsh Marine and Seawater Environments

S32750 excels in marine applications due to its outstanding resistance to chloride-rich seawater. Long-term immersion studies reveal its superior performance compared to other grades.

After 36 months in seawater, the corrosion rate of 316L was two orders of magnitude greater than that of S32750. The super duplex alloy maintained a consistently low corrosion rate, demonstrating its exceptional durability.

This reliability makes the 2507 alloy ideal for a wide range of marine equipment, including:

- Propellers, shafts, and rudders

- Pumps, valves, and fasteners

- Seawater cooling systems

- High-pressure components in desalination plants

Demanding Chemical Processing

Chemical processing plants utilize S32750 to handle aggressive media that would destroy lesser alloys. Its robust chemical composition provides excellent resistance to both organic and inorganic acids. The material performs reliably in contact with dilute sulfuric acid contaminated with chlorides and can even handle dilute hydrochloric acid. This capability allows engineers to use it in process streams where grades like 316L and 904L are unsuitable, ensuring equipment longevity and process safety.

Reducing Weight and Overall Project Cost

One of the most significant engineering advantages of S32750 is its ability to lower the total cost of a project. This benefit stems directly from its exceptional strength-to-weight ratio. Because the alloy is much stronger than conventional steels, engineers can design components with thinner walls and smaller cross-sections. This design flexibility allows for a direct reduction in the total volume of material required for pipes, vessels, and structural elements.

Using less material creates a cascade of cost-saving benefits throughout the project lifecycle.

- Lighter Components: Reduced material volume leads to lighter individual parts.

- Lower Fabrication Costs: Lighter components are easier to handle, position, and weld in the workshop.

- Reduced Transportation Expenses: Shipping lighter and smaller components to the project site is less expensive.

- Simplified Installation: On-site assembly requires less heavy-lifting equipment and fewer support structures.

Although the initial investment for a Super Duplex Steel S32750 Round Bar may be higher than for other materials, its overall cost-effectiveness is a critical factor. The material's high strength and durability significantly reduce long-term maintenance costs.

Lifecycle Cost Advantage 💡 The initial price of S32750 is only one part of the financial equation. Its long life and low maintenance requirements provide significant economic advantages over the entire asset lifecycle. This makes the higher upfront investment a strategic decision that pays off by preventing costly repairs and replacements down the line.

Ultimately, the ability to design lighter, more durable systems makes the 2507 alloy an economically sound choice for large-scale projects. The savings in fabrication, logistics, and long-term upkeep often outweigh the higher initial material price, delivering a lower total cost of ownership.

Super Duplex S32750 is the premium material choice for extreme conditions. Its superior strength and a Pitting Resistance Equivalent Number (PREN) over 40 make it essential where performance is non-negotiable. Engineers specify the 2507 alloy for the most demanding applications.

- Offshore oil drilling and production

- Subsea equipment

- Desalination and high-pressure RO plants

For less severe environments, standard Duplex 2205 or Austenitic 316L offer a more cost-effective balance of properties, making them suitable for a broader range of general-purpose uses.

FAQ

Why is S32750 more expensive than 316L?

S32750 contains higher amounts of critical alloying elements like chromium, molybdenum, and nitrogen. These elements provide its superior strength and corrosion resistance. The complex manufacturing process required to create this advanced alloy also contributes to its higher initial cost.

Can I substitute S32750 for all stainless steel applications?

Engineers reserve S32750 for the most demanding environments where other steels would fail. For less critical applications, grades like 2205 or 316L provide a sufficient and more cost-effective solution. The choice depends entirely on the specific service conditions.

What does a high PREN mean for S32750?

PREN stands for Pitting Resistance Equivalent Number. It predicts a steel's ability to resist pitting corrosion in chloride environments.

S32750's high PREN value (over 40) confirms its exceptional performance in aggressive settings like seawater, making it a highly reliable choice.

Is Super Duplex S32750 difficult to weld?

Welding S32750 requires specific procedures and skilled professionals. Welders must control heat input to maintain the alloy's balanced austenitic-ferritic microstructure. Following established industry guidelines ensures strong, corrosion-resistant welds that preserve the material's superior properties.

See Also

Achieving Optimal Outcomes: Steel Processing for Heat Exchanger Performance

Mastering Pass Partition Plate Welding: Expert Techniques for 2025

Industrial Semi-Welded Plate Heat Exchangers: A Comprehensive 2025 Overview

Molybdenum Plugs Assessment: Seamless Steel Pipe Manufacturing in 2025

Hygienic Design Standards: EHEDG Guidelines Versus 3A SSI Comparison