The 2025 Guide to 2507 Duplex Steel Elbow

A 2507 Duplex Steel Elbow is a high-performance pipe fitting that changes flow direction in critical systems. This component uses super duplex stainless steel UNS S32750, a grade offering superior performance over the standard duplex grade UNS S31803. Industries select it for exceptional mechanical strength and corrosion resistance, with capabilities that often exceed those of components like 904L Stainless Steel Pipe Fittings. It provides reliability in demanding environments such as offshore oil and gas, chemical processing, and desalination plants.

Key Takeaways

- A 2507 Duplex Steel Elbow is a strong pipe part. It changes the direction of flow in important systems. It works well in tough places like oil rigs and chemical plants.

- This steel is better than other types. It has more chromium, molybdenum, and nitrogen. These parts make it very good at fighting rust and corrosion.

- The 2507 steel is very strong. It lets engineers use thinner pipes. This saves money and makes systems lighter.

- Choosing the right supplier is important. Look for companies with ISO 9001 certification. This means they have good quality control.

- Ask suppliers important questions. Ask about delivery times and how they check quality. This helps you find a reliable partner.

Technical Specifications: UNS S32750 vs. S31803

Understanding the technical differences between super duplex UNS S32750 and standard duplex UNS S31803 is crucial for selecting the right material. The enhanced properties of S32750 stem directly from its enriched chemical makeup and superior mechanical capabilities.

Chemical Composition Comparison

The performance of a duplex steel is largely determined by its alloying elements. UNS S32750 contains higher percentages of chromium, molybdenum, and nitrogen. These elements significantly boost its resistance to corrosion. The table below outlines the key elemental differences based on ASTM/ASME standards.

| Element | UNS S31803 (%) | UNS S32750 (%) |

|---|---|---|

| Chromium (Cr) | 21.0–23.0 | 24.0–26.0 |

| Molybdenum (Mo) | 2.5–3.5 | 3.0–5.0 |

| Nitrogen (N) | 0.08–0.20 | 0.24–0.32 |

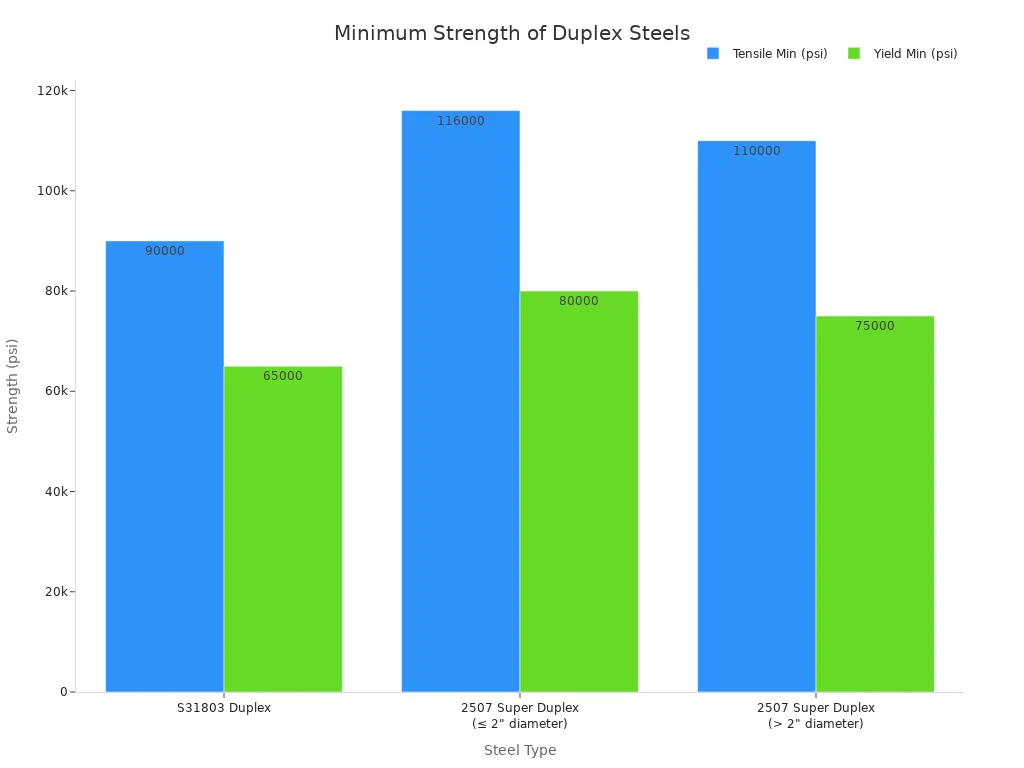

Mechanical Properties and Performance

A 2507 Duplex Steel Elbow delivers substantially higher mechanical strength than its S31803 counterpart. This increased strength allows for the design of lighter systems with thinner walls, reducing overall weight and cost. The Pitting Resistance Equivalent Number (PREN) for 2507 steel typically exceeds 42, giving it approximately twice the pitting corrosion resistance of 316L stainless steel.

Note: Engineers must consider temperature limitations. UNS S32750 faces a risk of embrittlement with prolonged exposure to temperatures above 250 °C (482 °F), making it unsuitable for high-temperature service.

Common Elbow Types and Dimensions

Manufacturers produce these fittings to meet diverse piping requirements. The dimensions and tolerances for buttweld elbows are governed by the ASME B16.9 standard. Common configurations include:

- Angles: 45°, 90°, and 180° returns.

- Bend Radii: Short Radius (1D), Long Radius (1.5D), and custom radii such as 3D, 5D, and 10D to accommodate various flow requirements.

This versatility ensures that a 2507 Duplex Steel Elbow can be integrated into nearly any high-performance piping layout.

Key Benefits of a 2507 Duplex Steel Elbow

Choosing a 2507 Duplex Steel Elbow provides significant operational and financial advantages for critical systems. Its advanced alloy composition translates directly into superior performance, long-term reliability, and enhanced safety in harsh operating conditions.

Advantages for Modern Industries

Modern industries gain a competitive edge by using UNS S32750 components. The high strength of 2507 duplex steel allows engineers to use a lighter gauge material. This achieves the same design strength as thicker nickel alloys. The reduction in material thickness leads to significant weight savings in piping systems and can lower overall fabrication costs.

Key advantages include:

- Exceptional Corrosion Resistance: It offers outstanding protection against pitting, crevice corrosion, and chloride stress corrosion cracking (SCC), extending the service life of equipment.

- Superior Mechanical Strength: Its high tensile and yield strength supports systems with higher pressure ratings and allows for thinner pipe walls, reducing material expenses.

- Cost-Effectiveness: The extended lifespan and reduced maintenance needs provide a lower total cost of ownership compared to less robust alloys.

Pro Tip: The combination of strength and corrosion resistance makes the 2507 Duplex Steel Elbow an ideal upgrade from standard stainless steels or even standard duplex grades in aggressive environments.

Primary Industrial Applications

The robust properties of UNS S32750 make it a first-choice material for industries where system failure is not an option. Fittings like elbows are critical components for directing fluid flow in these demanding sectors.

The oil and gas industry frequently uses Duplex 2507 stainless steel for offshore platforms and pipelines.

- Offshore Oil and Gas: Petro Canada successfully implemented Super Duplex 2507 piping in an offshore oil field near Newfoundland. This strategy was chosen specifically to combat severe saltwater corrosion.

- Chemical Processing: It handles aggressive chemicals, acids, and chlorides without degrading, ensuring process integrity.

- Desalination Plants: The material excels in reverse osmosis and brine handling systems due to its high resistance to chloride-rich seawater.

- Marine Systems: Shipbuilders use it for seawater cooling systems, ballast water treatment, and exhaust gas scrubbers.

How to Select a Manufacturer and Supplier in 2025

Selecting the right partner to source 2507 Duplex Steel Elbows is as critical as choosing the material itself. A reliable supply chain ensures project timelines are met, quality standards are upheld, and long-term performance is guaranteed. In 2025, procurement managers must look beyond price and evaluate a partner’s technical credentials, logistical capabilities, and commitment to quality.

Vetting a Manufacturer's Credentials

A manufacturer’s qualifications provide the first layer of assurance. Verifiable certifications and robust quality control systems separate premier manufacturers from the rest.

One of the most important credentials is ISO 9001 certification. This standard demonstrates a manufacturer's commitment to a comprehensive Quality Management System (QMS). An ISO 9001-certified facility adheres to strict principles that directly impact product quality:

- Raw Material Control: They implement processes to verify the quality of incoming steel billets, preventing defects from the start.

- Manufacturing Consistency: Production stages like forming and heat treatment are tightly controlled to ensure every elbow meets precise dimensional specifications.

- Rigorous Testing: Products undergo mandatory testing to confirm they meet material and performance standards.

- Documentation and Traceability: Each batch is documented from raw material to finished product, ensuring full traceability and accountability.

For projects in Europe, manufacturers may also hold a Pressure Equipment Directive (PED 2014/68/EU) Material Manufacturing Certification. While individual pipe fittings do not receive a CE mark, this certification confirms the manufacturer is approved to produce materials for PED-compliant pressure systems.

Expert Insight: A top-tier manufacturer validates product integrity using multiple non-destructive testing (NDT) methods. These tests detect surface and internal flaws without damaging the part. Common NDT methods for 2507 duplex steel elbows include Ultrasonic Testing (UT), Radiographic Testing (RT), and Liquid Penetrant Testing (LPT).

Finally, project managers can insist on third-party inspections for added confidence. Globally recognized agencies like Pro QC International and Benchmark International offer independent verification of a manufacturer's processes and final products, ensuring conformity to international standards.

Evaluating a Supplier's Reliability

A supplier acts as the crucial link between the manufacturer and the end-user. Their reliability hinges on logistical expertise, inventory management, and customer support. When sourcing internationally, buyers face potential logistical challenges, including communication barriers across time zones, complex customs documentation, and geopolitical tensions that can disrupt supply chains.

A dependable supplier mitigates these risks with a proven logistics network. Key performance indicators (KPIs) offer insight into their capabilities. For instance, an on-time delivery (OTD) rate is a powerful measure of reliability. While benchmarks vary, an OTD rate of 95% or higher is considered exemplary in industrial manufacturing.

Beyond delivery, a supplier’s value is evident in its after-sales service. Effective support policies build long-term partnerships and provide peace of mind. Look for suppliers who offer:

- Technical Documentation: Easy access to product training materials, installation guides, and data sheets.

- Responsive Support: Multiple contact channels (phone, email, chat) for quick resolution of technical queries or issues.

- Proactive Communication: Clear updates on order status and potential delays.

Key Questions for Your Potential Supplier

Engaging a potential supplier with specific, targeted questions is the best way to assess their capabilities and transparency. A prepared supplier should be able to answer the following with confidence and detail.

Key Inquiry Checklist 📝

- What are your typical lead times for a bulk order of 2507 elbows?

- A supplier's answer reveals their inventory strategy. In-stock items may ship in 5-10 days, while new production orders can range from 15 to 50 days, depending on quantity and complexity.

- Can you describe your quality control checkpoints during manufacturing?

- A detailed response should include checkpoints like material verification (spectral analysis), dimensional inspection (using calibrated tools), non-destructive testing (UT, RT), and pressure testing (hydrostatic tests).

- Can you provide client references or case studies from the oil and gas or chemical processing industries?

- Proven experience in demanding sectors demonstrates an understanding of critical application requirements and a history of success.

- What is your policy for handling non-conforming products or warranty claims?

- A clear policy should outline the process for returning a non-conforming product, the available remedies (repair, replacement, or refund), and any warranty exclusions.

Asking these questions helps procurement teams make an informed decision, ensuring they partner with a supplier who can deliver high-quality 2507 Duplex Steel Elbows on time and with the necessary documentation.

For applications demanding high strength and superior corrosion resistance, the 2507 Duplex Steel Elbow is the optimal choice. Selecting a qualified partner is critical for project success, helping to prevent delays caused by quality issues or late deliveries. Procurement teams should prioritize suppliers with verified ISO 9001 certification, complete material traceability (MTCs), and a high on-time delivery rate. Engaging a certified supplier ensures project managers secure the right components for their critical systems in 2025.

FAQ

Why choose a 2507 elbow over a standard duplex S31803?

Engineers select 2507 (UNS S32750) for its superior performance in highly corrosive environments. Its enhanced chemical composition provides greater resistance to pitting and crevice corrosion. The material’s higher strength also allows for designs with thinner walls, reducing overall system weight and cost.

Is 2507 duplex steel difficult to weld?

Welding 2507 duplex steel requires specific procedures. Fabricators must use appropriate filler metals and control heat input to maintain the alloy's balanced microstructure. Proper welding ensures the component retains its excellent mechanical strength and corrosion resistance in the heat-affected zone.

How does the cost of 2507 compare to 316L stainless steel?

A 2507 Duplex Steel Elbow has a higher initial material cost than a 316L stainless steel fitting. However, its extended service life and minimal maintenance needs in harsh conditions often result in a lower total cost of ownership over the project's lifetime.

What is a Material Test Certificate (MTC)?

A Material Test Certificate (MTC), or EN 10204 3.1 certificate, is a quality assurance document. It provides complete traceability by detailing the elbow's specific chemical composition, mechanical properties, and the results of any non-destructive tests, confirming its compliance with international standards.

See Also

Industrial Semi-welded Plate Heat Exchangers: A Comprehensive 2025 Operational Guide

Welding Pass Partition Plates: Expert Techniques and Best Practices for 2025

Molybdenum Plugs in Seamless Steel Pipe Production: A 2025 Performance Review

Hygienic Design: Comparing EHEDG Guidelines with 3A SSI Standards Effectively

Shell and Plate Heat Exchangers: Performance Comparison and Analysis for 2025