A 2025 Guide to Black-Eyed Pea Sorting Machines

Selecting the ideal black eyed peas sorting machine enhances product quality and operational efficiency. Each leading model offers distinct advantages for specific business needs.

- Bühler SORTEX A Series: Delivers the best overall value for growing operations.

- TOMRA 3C: Provides the highest accuracy for premium product lines.

- Satake PIKASEN FMS-2000: A budget-friendly choice for new businesses.

- Key Technology VERYX B140: Features the most compact design for limited spaces.

- Meyer M-Series: Offers the easiest operation for non-technical teams.

How to Choose the Right Sorter for Your Business

Selecting the right sorter involves a careful analysis of your operational needs. Businesses should evaluate several key factors to ensure their investment aligns with production goals and facility constraints.

Sorting Accuracy and Technology

Modern sorters achieve remarkable precision. Many machines deliver a sorting accuracy of ≥99.99% for removing foreign materials and color defects. Key performance indicators help quantify this effectiveness.

- Net Selection Rate: This measures the proportion of high-quality peas correctly identified.

- Rejection Rate: This shows the percentage of unwanted particles removed from the product stream. A higher rejection rate results in a cleaner final product, directly impacting quality.

Throughput and Capacity

Throughput measures the volume of peas a machine can process, typically in kilograms or tons per hour (kg/hr or t/hr). Capacity can range from 500 kg/hr for smaller units to over 8 t/hr for large industrial models. Suppliers often calculate these figures based on a standard contamination rate, so actual performance may vary with your raw material's impurity level.

Footprint and Integration

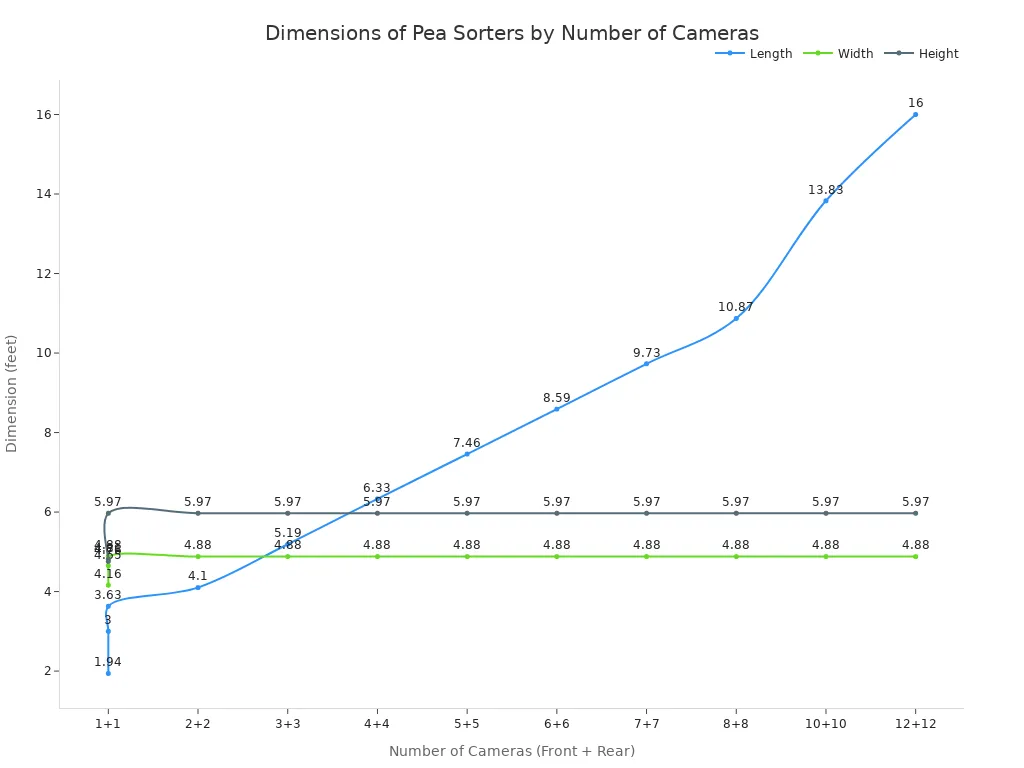

A sorter must fit within your existing facility. Machine dimensions increase with capacity, particularly the number of cameras used for inspection.

Integration requires compatibility with existing equipment. The black eyed peas sorting machine must match the flow rate of conveyors and have its control system link with the plant's automation network.

Integration requires compatibility with existing equipment. The black eyed peas sorting machine must match the flow rate of conveyors and have its control system link with the plant's automation network.

Budget and Return on Investment

The initial purchase price is only part of the total investment. Long-term value comes from durability, efficiency, and reduced labor costs.

Pro Tip: Look for features that enhance long-term reliability. A stainless steel construction provides corrosion resistance, while CE certification ensures the machine meets high safety standards, contributing to a stronger return on investment.

Detailed Reviews: The Top 5 Black Eyed Peas Sorting Machine Models

Choosing the right machine requires a close look at what each model offers. This section breaks down the top five sorters, highlighting their unique strengths to help you match a machine to your specific production goals.

1. Bühler SORTEX A Series: Best Overall Value

The Bühler SORTEX A Series represents a powerful balance of performance, durability, and cost-effectiveness. It is an excellent choice for growing businesses that need reliable, high-volume sorting without the premium price tag of ultra-specialized machines. The series is known for its robust construction and adaptable technology.

Bühler has demonstrated the SORTEX A's capabilities in demanding industrial applications. Case studies on maize processing show the machine's effectiveness at removing defective kernels and foreign material. This same precision technology, featuring advanced cameras, is adaptable to legumes. Bühler's reputation as a leading vendor in seed processing provides confidence in the machine's long-term performance and support, solidifying its position as a top value investment.

2. TOMRA 3C: Highest Sorting Accuracy

The TOMRA 3C sets the industry standard for sorting precision. Processors aiming for a premium product with near-zero defects will find this machine indispensable. It excels at identifying and removing the most challenging imperfections, from subtle color variations to foreign materials that mimic the size and shape of black-eyed peas.

This exceptional accuracy comes from a sophisticated combination of detection technologies.

- It integrates high-resolution color cameras with dual lasers for unparalleled detection of color, shape, and foreign matter.

- The camera and laser units provide bilateral inspection, viewing each pea from both sides.

- An intelligent rejection system uses high-speed air jets to remove defects just milliseconds after detection.

Note: The TOMRA 3C's precision minimizes the rejection of good products, maximizing yield and profitability for high-end product lines.

3. Satake PIKASEN FMS-2000: Most Budget-Friendly

New businesses and smaller operations often face tight capital constraints. The Satake PIKASEN FMS-2000 addresses this need directly, offering reliable full-color RGB sorting at an accessible price point. This machine provides a significant upgrade from manual sorting, enabling startups to improve quality control and efficiency from day one.

While it may not have the advanced features of higher-end models, its performance is more than adequate for standard quality requirements. The PIKASEN is a workhorse designed for simplicity and effectiveness. For businesses entering the market, its affordability makes it a practical first step into automated sorting. A look at the used market often reveals its attractive entry-level cost.

| Feature | Detail |

|---|---|

| Example Price (Used) | ~$50,000.00 |

| Typical Warranty | Manufacturer warranties are often transferable. |

4. Key Technology VERYX B140: Most Compact Design

Floor space is a premium in many processing facilities. The Key Technology VERYX B140 is engineered specifically for plants with limited room, delivering high-capacity sorting in a compact footprint. This belt-fed black eyed peas sorting machine proves that a smaller size does not mean a sacrifice in performance.

The VERYX B140's design cleverly maximizes its processing capability.

- It features a 1400-mm wide inspection zone, which is about 15% wider than many comparable sorters.

- This extra width boosts throughput, allowing it to process up to 10 metric tons per hour.

- The wider belt also improves product singulation, giving cameras a clearer view of each pea and enhancing sorting accuracy.

5. Meyer M-Series: Easiest to Operate

Technology is only effective if your team can use it confidently. The Meyer M-Series excels with its intuitive design and user-friendly interface, making it the top choice for facilities with limited technical staff. The machine simplifies complex sorting tasks into straightforward operations, reducing the learning curve and minimizing operator error.

Operator Focus: The M-Series often features one-button start-up, pre-programmed sorting modes for different products, and a clear touchscreen display. This focus on usability ensures consistent performance regardless of who is operating the machine, reducing downtime and training costs. It empowers your existing team to manage quality control effectively without needing specialized engineers on staff.

Comparison at a Glance: 2025 Sorter Showdown

To simplify your decision-making process, this table provides a direct comparison of the top models. Each black eyed peas sorting machine is evaluated on its price, capacity, and standout features to help you identify the best fit for your operational needs.

Machine Model

Price Range

Throughput (kg/hr)

Key Feature

Best For

| Machine Model | Price Range | Throughput (kg/hr) | Key Feature | Best For |

|---|---|---|---|---|

| Bühler SORTEX A | Mid-High | 1,000 - 8,000 | Adaptable camera technology | Growing operations needing value. |

| TOMRA 3C | Premium | 1,000 - 5,000 | Dual laser & camera inspection | Premium product lines needing accuracy. |

| Satake PIKASEN FMS-2000 | Entry-Level | 500 - 3,000 | Full-color RGB sorting | New businesses on a tight budget. |

| Key Technology VERYX B140 | High | Up to 10,000 | Wide belt for high capacity | Space-limited facilities. |

| Meyer M-Series | Mid-Range | 500 - 6,000 | Intuitive, one-button operation | Teams with limited technical staff. |

Quick Tip: Throughput figures are often based on ideal conditions. Always discuss your specific product and contamination levels with the manufacturer to get a more accurate performance estimate for your facility.

The best black eyed peas sorting machine directly aligns with your business needs for budget, volume, and quality. This equipment is a critical investment in your operational future.

A sorter enhances quality control, protects brand reputation, and can reduce labor costs by up to 30% in logistics.

Use our comparison table to find the model that best matches your 2025 goals and secure your investment.

FAQ

How much maintenance do these sorters require?

Most modern sorters require minimal daily maintenance. Operators perform routine cleaning and calibration checks. Manufacturers recommend annual professional servicing to ensure long-term reliability and optimal performance.

Can one machine sort different types of beans?

Yes, many sorters are versatile. Operators can load pre-programmed settings for different products. This allows a single machine to process black-eyed peas, lentils, and other legumes efficiently.

How does a sorter impact overall product yield?

A high-precision sorter maximizes yield. It accurately removes only defective items. This process minimizes the rejection of good products, increasing the final volume of saleable goods.

See Also

Essential Capsule Checkweighers: A 2025 Buyer's Guide for Smart Investments

Crucial Industrial Checkweighers: Every Food Plant's Must-Have for Efficiency

Next-Gen Folder Gluer Innovations: Enhancing 2025 Carton Line Performance

Tablet Sampling Machines: The Definitive Lab Selection Guide for Precision

Sourcing X-Ray Inspection Machines: Top Chinese Suppliers for Quality