Data-backed ways to boost 2 5-Furandicarboxylic acid sustainability

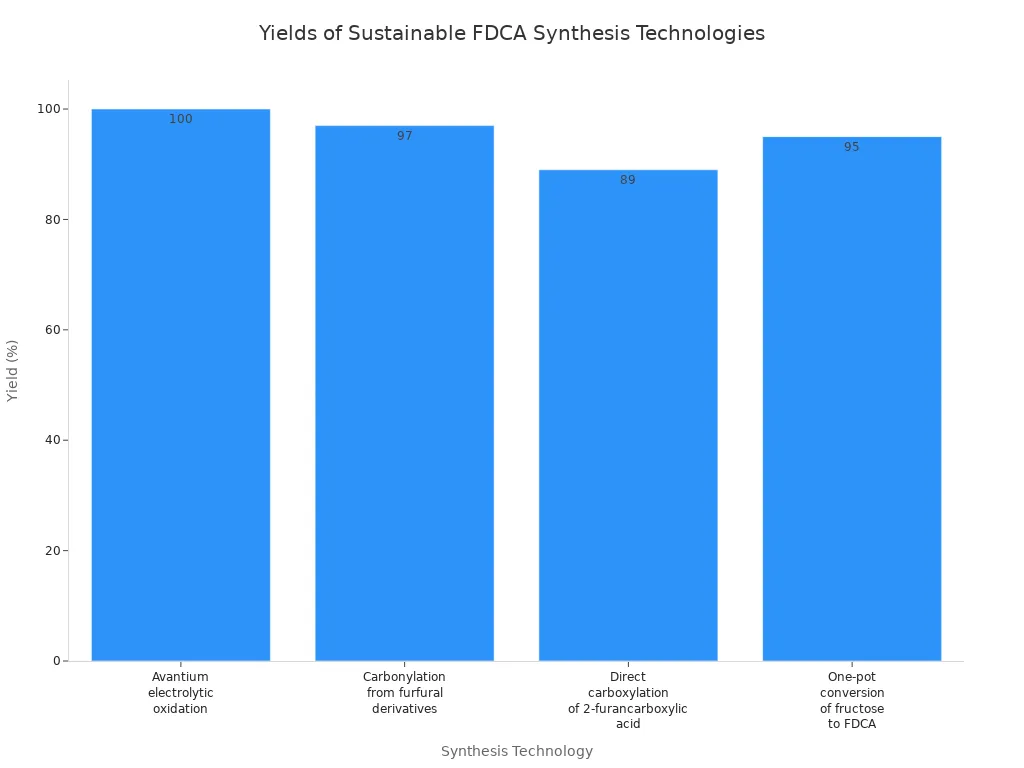

You see rapid growth in demand for 2 5-Furandicarboxylic acid, driven by advancements in biobased synthesis and catalytic innovations. Technologies like one-pot conversion of fructose yield up to 95%, minimizing hazardous by-products.

Life cycle assessment highlights electrocatalytic routes as environmentally preferable, emphasizing continuous improvement in process efficiency.

Key Takeaways

- Use renewable biomass and biobased synthesis methods to produce 2 5-Furandicarboxylic acid, which lowers carbon emissions and supports a circular economy.

- Adopt green catalysts, solvents, and optimized reaction conditions to increase yield, reduce waste, and improve process efficiency.

- Focus on process improvements like enzyme selection, reactor design, and feedstock choice to make production scalable, cost-effective, and environmentally friendly.

Sustainable Synthesis Technologies for 2 5-Furandicarboxylic acid

Biobased Routes and HMF Oxidation

You can boost the sustainability of 2 5-Furandicarboxylic acid by choosing biobased synthesis routes. The most widely adopted method uses catalytic oxidation of 5-hydroxymethylfurfural (HMF) with gold-based catalysts. This process efficiently converts HMF, which comes from renewable biomass, into FDCA. When you use glucose or fructose as starting materials, you support a renewable alternative to petroleum-based chemicals.

Biobased synthesis offers several advantages:

- You use renewable resources, which helps reduce your carbon footprint.

- FDCA-based polymers show better thermal stability and gas barrier properties than traditional plastics.

- Techno-economic studies show that producing FDCA from starch, glucose, or high-fructose corn syrup is both feasible and scalable.

- Electrocatalytic oxidation with advanced anion exchange membranes increases process efficiency and supports large-scale production.

You can also use enzymatic cascades and whole-cell biocatalysis to convert HMF to FDCA. Enzymatic cascades, such as those involving Bacillus pumilus laccase and Colletotrichum gloeosporioides alcohol oxidase, achieve up to 97.5% FDCA yield at small scale and maintain high selectivity. These biocatalytic methods avoid harsh chemicals and operate under mild conditions, making them eco-friendly and cost-effective.

| Catalyst | HMF Conversion (%) | FDCA Yield (%) | Reaction Time | Temperature | O2 Pressure | FDCA Formation Rate (μmol min⁻¹ g⁻¹) |

|---|---|---|---|---|---|---|

| Co1.3-N-C | 100 | 99.6 | 1 hour | 90 °C | 0.1 MPa | 52.34 |

| CoOx nanoparticles | N/A | 95 | 30 hours | 80 °C | 0.5 MPa | N/A |

| Co-Cu-CNx | N/A | 96 | 12 hours | N/A | N/A | N/A |

| FeNPs@NH2-SBA-15 | 100 | 89.4 | N/A | N/A | 0.6 MPa | N/A |

Tip: When you select biomass-derived HMF as your feedstock, you directly support a circular bioeconomy and lower the environmental impact of 2 5-Furandicarboxylic acid manufacturing.

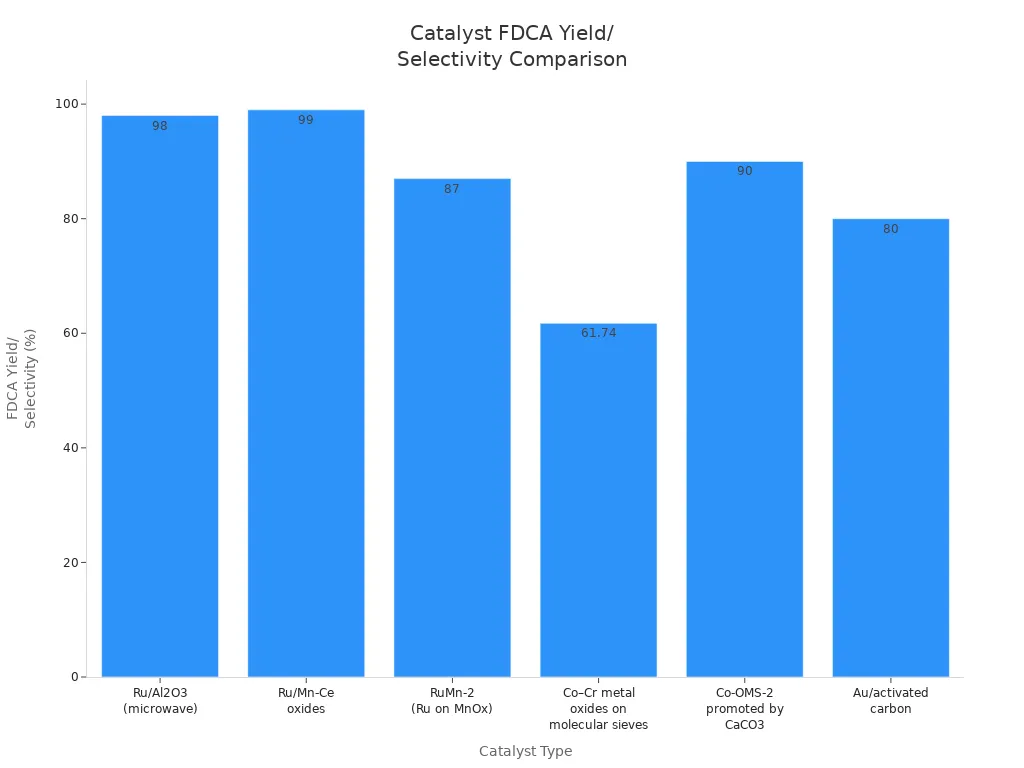

Catalytic and Green Chemistry Approaches

You can further improve sustainability by adopting advanced catalytic and green chemistry strategies. Recent progress includes chemocatalysis, biocatalysis, photocatalysis, and electrocatalysis. Biocatalysis stands out for its mild reaction conditions, lower cost, and high selectivity. You can use enzymes or engineered microbes to convert HMF and related compounds into FDCA, which reduces the need for harsh chemicals.

Green chemistry approaches focus on using heterogeneous catalysts, such as alloyed AuPd(2:1)/C, which show high activity and resist deactivation from impurities in unrefined biomass. This allows you to process crude HMF directly, skipping purification steps and reducing waste. Optimizing the amount of base in the reaction can further increase FDCA yield.

You can also use green solvents like γ-valerolactone (GVL) mixed with water. This solvent system improves FDCA solubility, enables easier product separation, and eliminates the need for corrosive acids or bases. Heterogeneous catalysts like Pt/C provide high yields and can be reused, which lowers costs and waste.

| Catalyst Type | FDCA Yield/Selectivity | Stability/Recyclability | Reaction Conditions/Notes |

|---|---|---|---|

| Ru/Al2O3 (microwave) | Up to 98% selectivity | Excellent recyclability and sustained activity | 140 °C, 30 bar O2, alkaline aqueous solution (Na2CO3) |

| Ru/Mn-Ce oxides | ≥99% yield | Remarkable stability over multiple cycles | Oxygen and water as green oxidants, strong metal-support interaction |

| Co–Cr metal oxides | 61.74% yield | Retains 99.95% activity over 5 cycles | One-pot conversion from biomass, sustainable and cost-effective |

| Co-OMS-2 + CaCO3 | 90% yield | Enhanced oxidation capacity and stability | Neutral conditions, 120 °C, 1 MPa O2, CaCO3 additive |

| Au/activated carbon | Up to 80% yield | Some stability limitations for Pt and Pd | 3 bar O2, 60 °C, NaOH solvent |

Note: By choosing green solvents and recyclable catalysts, you help reduce waste, energy use, and environmental impact in 2 5-Furandicarboxylic acid production.

Process Optimization and Feedstock Selection

You can maximize efficiency and sustainability by optimizing your process and carefully selecting feedstocks. Enzyme selection plays a key role. For example, hydroxymethylfurfural oxidase (HMFO) offers better stability and performance than other enzymes, especially when you use variants like V367R and 8BxHMFO. Adding catalase to remove hydrogen peroxide can increase FDCA yield up to ninefold.

Operational parameters matter. Setting the pH at 8.0 and managing oxygen concentration ensures optimal FDCA production. Reactor design improvements, such as continuous-flow microreactors, boost oxygen transfer and scalability.

| Optimization Strategy | Description & Impact |

|---|---|

| Enzyme Selection | HMFO preferred for stability and efficient oxidation of FFCA, the limiting step in FDCA production. |

| Enzyme Variants | V367R and 8BxHMFO achieve full conversion of 6 mM HMF to FDCA in 48 hours. |

| Catalase Addition | Removes inhibitory H2O2, increasing enzyme half-life and FDCA yield (up to 9-fold improvement). |

| Operational Parameters | Optimal pH 8.0, atmospheric O2 sufficient for variants, higher O2 may enhance scalability. |

| Reactor Design Improvements | Continuous-flow microreactors improve oxygen transfer rates and scalability. |

| Cost Considerations | FAD cofactor addition is cost-prohibitive and excluded from optimized conditions. |

Feedstock selection also shapes sustainability. When you use biomass-derived HMF from glucose or fructose, you replace fossil resources and support renewable chemical production. Nickel-based catalysts can convert crude HMF from glucose dehydration, offering recyclability and reducing reliance on noble metals.

You can further reduce energy consumption by optimizing media components, such as substrate concentration, pH, and temperature. Using cheap feedstocks like thermal algal hydrolyzate and optimizing recovery parameters can lower both costs and energy use.

By focusing on process optimization and renewable feedstocks, you ensure that 2 5-Furandicarboxylic acid production remains efficient, scalable, and environmentally responsible.

Environmental Impact and Life Cycle Assessment of 2 5-Furandicarboxylic acid Production

Carbon Footprint and Resource Efficiency

You can significantly lower your environmental impact by choosing 2 5-Furandicarboxylic acid made from renewable biomass. When you use plant-based sugars instead of petroleum, you help reduce greenhouse gas emissions. Studies show that producing PEF from 2 5-Furandicarboxylic acid can cut the carbon footprint by up to 50% compared to PET. The process uses less energy and locks CO₂ in the polymer, which further reduces emissions. If you use waste lignocellulosic biomass and CO₂ as raw materials, you also lower production costs and avoid fossil fuels. Life cycle assessments (LCAs) highlight that the environmental benefits depend on process efficiency, production scale, and how you allocate impacts from biomass cultivation.

Waste Generation and Process Intensification

You can improve sustainability by focusing on waste reduction and process intensification. Laboratory-scale production of 2 5-Furandicarboxylic acid often creates more waste due to high use of consumables. Industrial-scale processes, however, show better resource efficiency. When you use advanced catalysts and continuous-flow reactors, you minimize by-products and energy use. LCAs also examine marine and freshwater eutrophication, which can result from biomass-derived chemical production. By optimizing your process and using renewable feedstocks, you help reduce waste and lower the risk of environmental harm.

Challenges and Data-Driven Opportunities

You face several challenges in sustainable 2 5-Furandicarboxylic acid production:

| Challenge | Explanation |

|---|---|

| High production costs | Bio-based production needs expensive feedstocks and energy, raising costs. |

| Fluctuating raw material prices | Prices for renewable feedstocks change often, making planning difficult. |

| Stringent environmental regulations | Strict rules increase compliance costs and limit growth. |

| Lack of economies of scale | Limited large-scale infrastructure keeps costs high. |

You can address these challenges with data-driven solutions:

- Use AI and machine learning to optimize chemical processes and reduce waste.

- Discover new catalysts that make production more efficient.

- Apply real-time monitoring and process simulation to improve quality and efficiency.

- Shift to diverse renewable biomass sources, including agricultural waste.

- Integrate lifecycle assessment and circular economy principles for better product development and recycling.

By adopting these strategies, you can make 2 5-Furandicarboxylic acid production more sustainable and cost-effective.

You drive sustainability by using biomass feedstocks, optimizing energy use, and adopting green catalysts. Focus on developing bio-based polymers, expanding production, and collaborating across sectors. Keep collecting process data and innovating with new biocatalysts and reactor designs. These best practices ensure continuous improvement and a greener future.

FAQ

What makes biobased FDCA more sustainable than petroleum-based alternatives?

You use renewable feedstocks, which lowers greenhouse gas emissions. Biobased FDCA also supports a circular economy and reduces reliance on fossil resources.

How can you improve FDCA yield during synthesis?

You optimize catalyst choice, reaction conditions, and feedstock purity.

Tip: Use continuous-flow reactors for better oxygen transfer and higher yields.

Which data should you track for sustainable FDCA production?

You monitor energy use, carbon footprint, waste generation, and product yield.

- Life cycle assessment (LCA) data helps you identify improvement opportunities.